Throughout the years, one thing we’ve always understood at E-Fab is very straightforward, in aerospace engineering, there’s no room for error. Cruising at altitudes of 35,000 feet and beyond, where pressures drop, temperatures plunge, and systems run at the edge of performance, every component must function flawlessly. Among these critical components are aerospace fluid filters and performance filtration screens, the often-forgotten filtration products that ensure everything from fuel purity to electronic signal clarity, as well as protection from particulates, operates consistently and reliably, from take-off to landing.

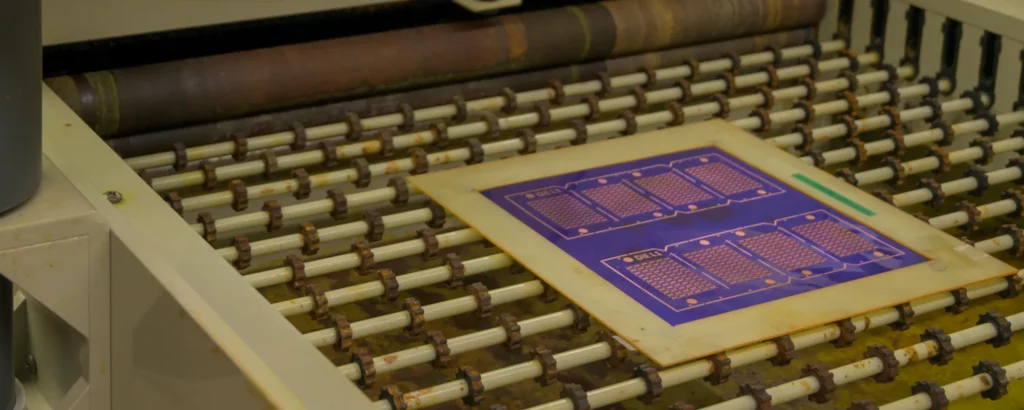

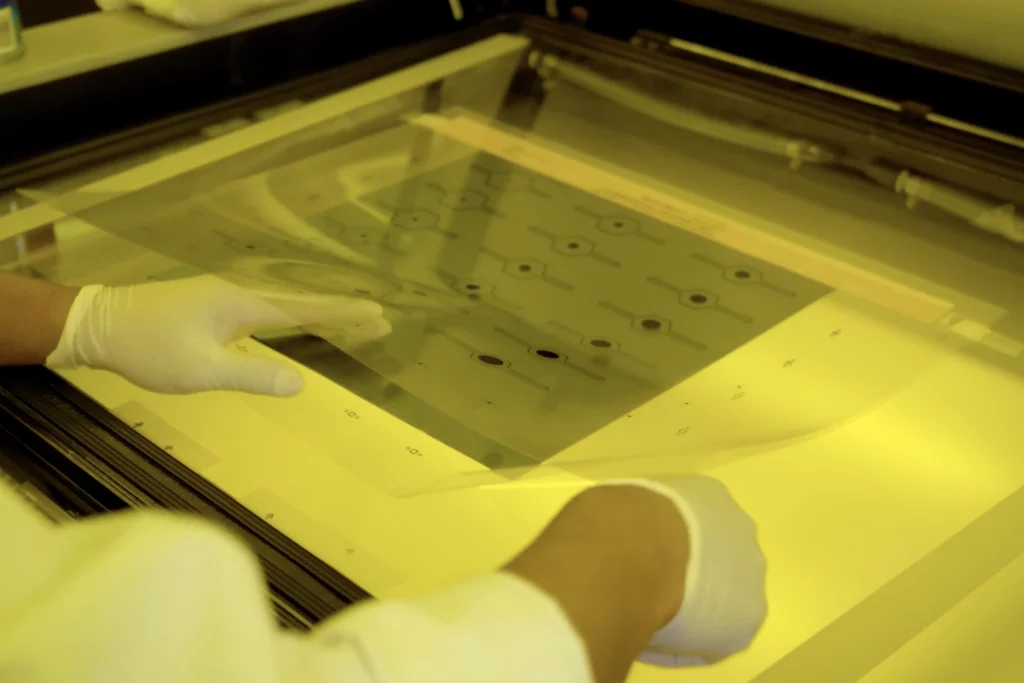

In aerospace, precision isn’t optional, it’s the difference between safe operation and catastrophic failure. That’s why engineers in the aerospace industry turn to photochemical machining (PCM), a specialized manufacturing process that delivers unmatched precision for high-performance aerospace filters and screens. E-Fab has decades of experience helping numerous customers pioneer innovative technology to make air travel exceptionally safe and reliable.

Why Aerospace Filters Are Critical Components

Aerospace filters and screens are purpose-built to defend vital systems from contaminants, pressure surges, temperature extremes, and electromagnetic interference. These high-performance components are designed with demanding specifications and operate in some of the harshest environments on Earth, and beyond. The design and selection of aerospace filters and screens depend on the specific case or operational scenario they are intended for, ensuring optimal performance under unique environmental and functional requirements.

Key Functions of Aerospace Filters & Screens

- Debris Filtration: Prevents particulate contamination in critical systems like fuel, hydraulics, and pneumatics.

- Fluid Flow Control: Ensures regulated, uninterrupted flow in fuel lines, lubrication paths, and cooling systems.

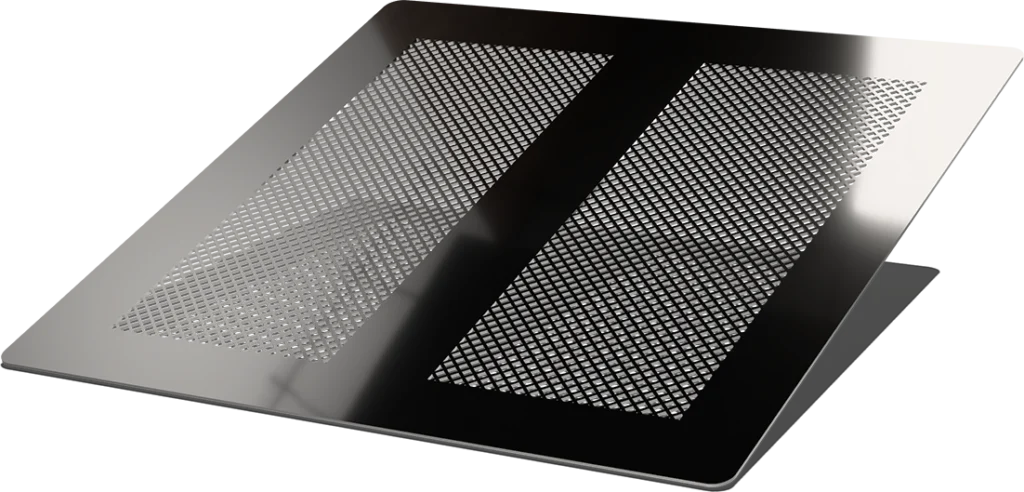

- Wire Mesh and Screens: High-resolution etched mesh blocks interference while allowing ventilation and visibility for heat-sensitive or display electronics.

Application Areas in the Aerospace Industry

- Jet Engines: Protect turbine blades and fuel systems from foreign object damage.

- Avionics: Safeguard sensitive circuits with EMI shielding screens.

- Fuel & Hydraulic Systems: Filter micro-contaminants to protect pumps, valves, and actuators.

Environmental Challenges

- High Vibration: Sustained turbulence and engine operation.

- Extreme Temperatures: From subzero stratospheric conditions to high engine heat.

- Pressure Swings: Rapid decompression and pressurization cycles.

These filters must be extremely lightweight, corrosion resistant, and geometrically precise, traits that can be difficult to achieve through traditional manufacturing. This is where photochemical machining stands out, and where E-Fab steps in.

The Precision Advantage of Photochemical Machining

Photochemical machining (PCM), also known as chemical etching, is the go-to method for producing delicate, high-precision metal components without the stresses introduced by mechanical tooling.

Key Advantages

- Stress-Free Processing: PCM doesn’t involve cutting forces, so components retain their material integrity with zero mechanical distortion.

- Ultra-Fine Geometries: Etching allows for micron-scale apertures and patterns impossible to achieve with CNC or stamping.

- No Burrs, No Warping: Finished parts require no secondary deburring or straightening.

- Material Versatility: Easily processes aerospace-grade alloys like stainless steel, titanium, Inconel, and nickel with consistent results.

Whether for EMI shielding in avionics or fuel filtration in jet engines, the parts produced by PCM meet tight tolerances with repeatable quality, features that are critical in high-reliability aerospace applications and essential for various equipment.

Custom Screens and Filters: What We Can Etch

At E-Fab, we specialize in etching aerospace filters and screens tailored to exact performance specifications for our clients and their projects.

As a company with a long history of innovation and technical development, E-Fab has collaborated with major aerospace manufacturers, to deliver advanced filtration solutions that meet the demanding needs of the industry.

Here’s what we can engineer for you:

Mesh Sizes & Open Area Control

Need precise control overflow rates or filtration thresholds? PCM allows for exact control of hole sizes, shapes, and densities. This enables engineers to fine-tune open area percentages and filter behavior.

Flow-Optimized Patterns

Etched patterns can be customized for laminar flow, pressure drop reduction, or debris separation, optimized for your specific fluid dynamics. This can extend the life of the screen while also optimizing performance.

Fine Apertures & Uniformity

With PCM, micro-apertures can be etched into metal substrates with extreme dimensional accuracy, ensuring uniformity across thousands of parts.

Multilayer or Stacked Filter Designs

By layering multiple etched screens, E-Fab can create filters with graded filtration, mechanical strength, or multi-functional performance, which can include combining EMI shielding and airflow control.

Why PCM Outperforms Traditional Methods

When manufacturing aerospace filters and screens, traditional techniques fall short in key areas. Here’s how PCM compares:

CNC Machining

Strengths: Good for thick metals, structural parts

Limitations: Poor for ultra-thin parts, costly

Stamping

Strengths: Fast for simple geometries

Limitations: Increased tooling cost, limited complexity, potential warping, burrs

Laser Cutting

Strengths: Good for rapid prototyping

Limitations: Heat-affected zones, edge roughness, tapering, slag

Photochemical Machining

Strengths: Ideal for thin, complex, high-precision parts

Limitations: Limited to 2D geometries (can be stacked for 3D function)

PCM excels in flatness, tolerances, and edge quality, making it ideal for aerospace performance filtration screens that cannot afford deviation or defects. Additionally, the low-cost tooling and rapid setup make it perfect for both prototyping and full-scale production.

Why Choose E-Fab as Your Aerospace Filters Manufacturer?

E-Fab brings decades of experience, material science expertise, technology, and process control to every aerospace component we manufacture. As a trusted supplier across the aerospace, medical, and electronics industries, we are known for precision, repeatability, and reliability.

Our Advantages:

- Aerospace Experience: We understand mission-critical components and performance at altitude.

- Short Lead Times: Rapid prototyping and agile production ensure we meet your development cycles.

- In-House Engineering: Our expert team collaborates on design, material selection, and performance optimization.

- Material Expertise: From titanium to Inconel, we process the toughest aerospace materials with ease.

- Certifications & Compliance: We operate under strict quality controls and adhere to aerospace standards, including AS9100 certification.

E-Fab is not just a vendor; we’re your manufacturing partner, ready to solve your toughest performance challenges with precision-etched solutions.

Precision That Flies

In aerospace, the margin for error is zero. Whether you’re developing next-gen propulsion systems, satellite avionics, or ultra-reliable fuel filters, every part must meet the highest standard and include advanced features. That’s why photochemical machining is the ideal solution for manufacturing aerospace filters and screens, components that must meet extreme performance, reliability, and weight requirements at altitude.

With E-Fab, you’re choosing a partner with the technology, experience, and commitment to deliver precision that performs when the stakes are highest, ensuring safety for passengers.

Let’s Build Filters That Won’t Fail

Work with E-Fab to engineer a variety of precision solutions from the inside out.