Accuracy and durability are the hallmarks of well-designed and manufactured parts produced by precision metal forming. E-Fab’s expert forming capability starts with CAD modeling by our engineering team. From there, our manufacturing floor, where engineers take machine code to form precise metal parts to exacting standards and specifications.

Our manufacturing experts perform a wide range of precision forming techniques and processes, delivering accurate and reliable parts. We send each piece through careful finishing and an exacting Quality Assurance process before delivery.

Heat Treating

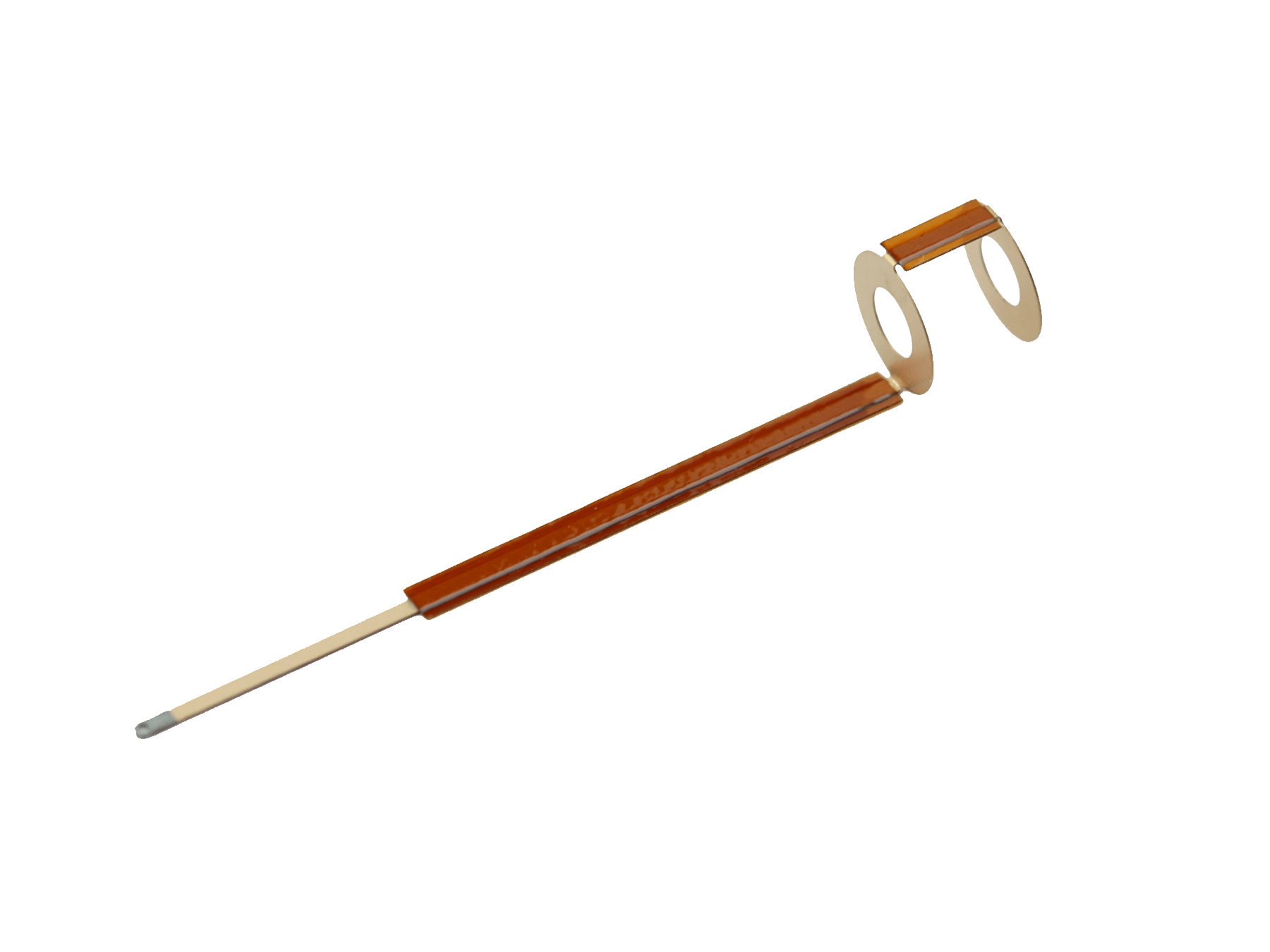

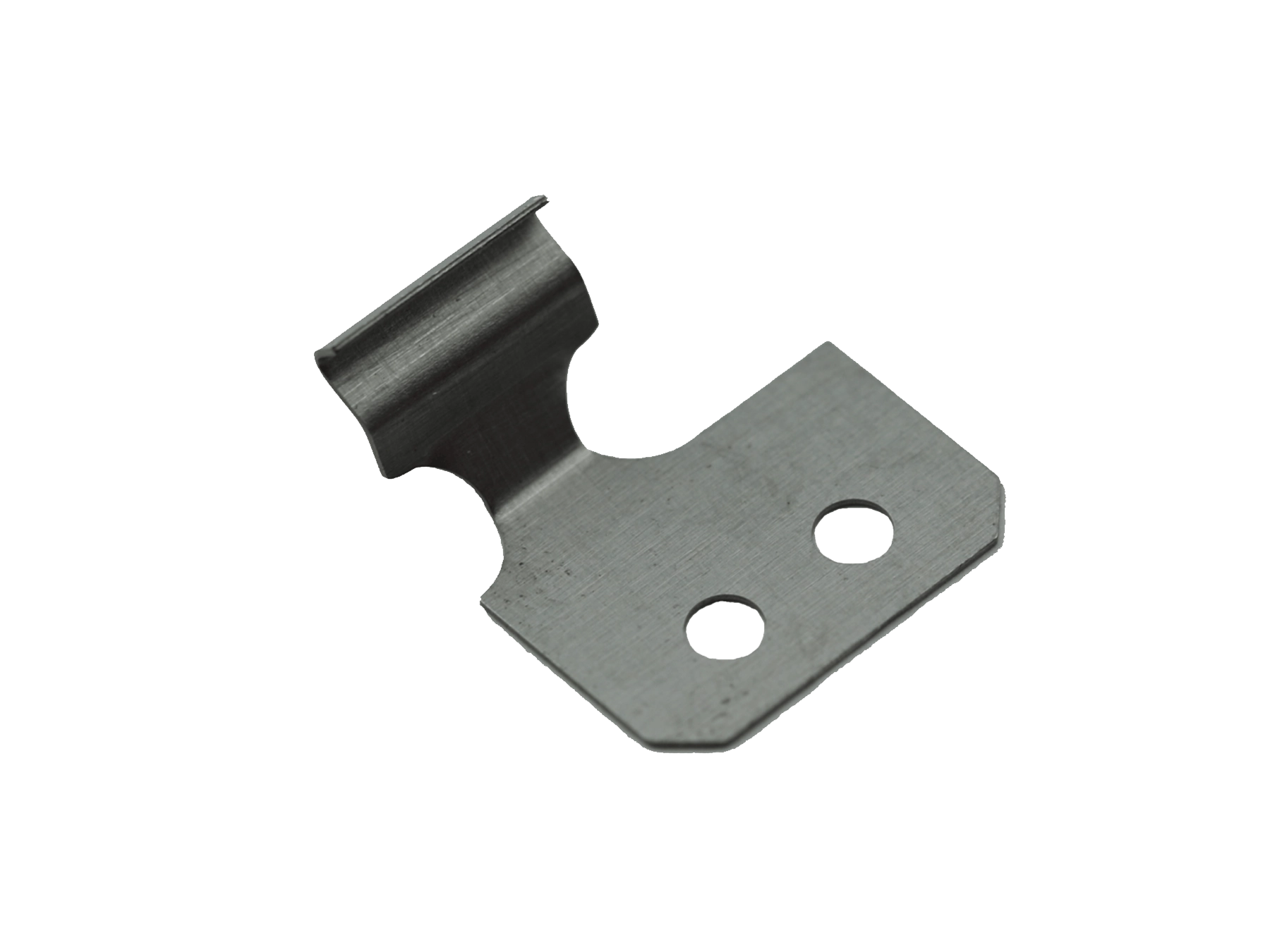

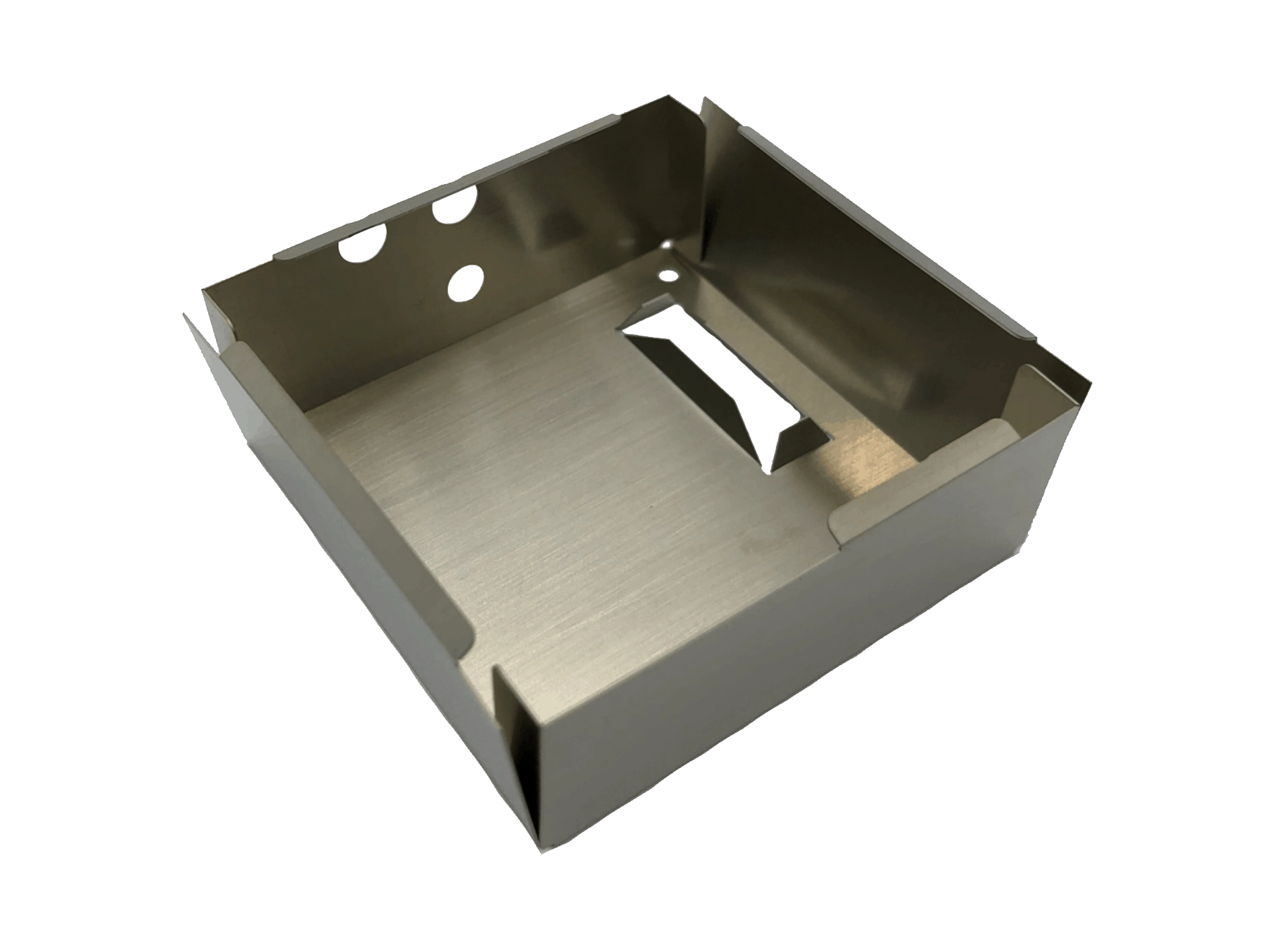

Bending

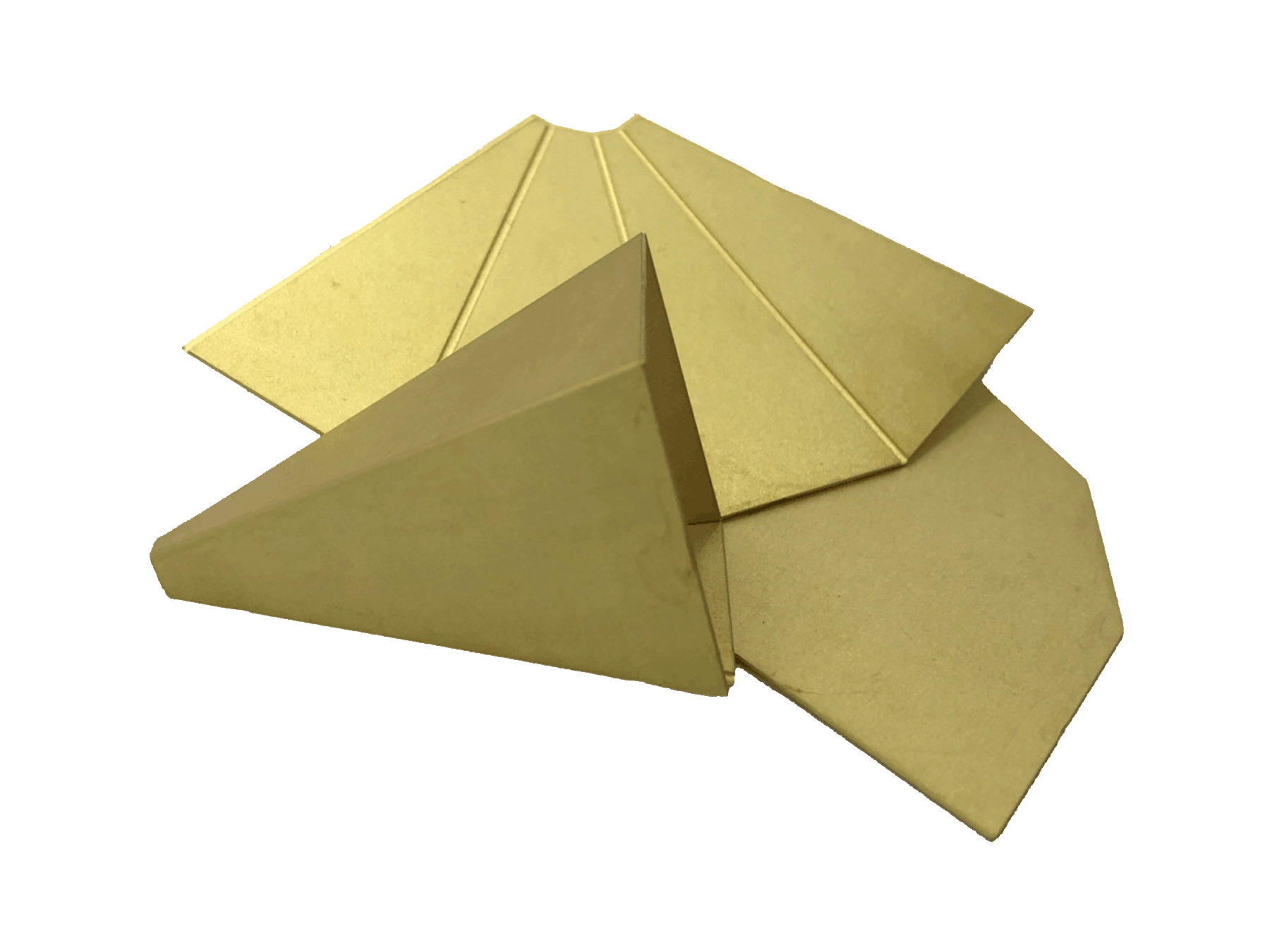

Press Forming

Drilling

Finishing

Coating

Painting

We are experts at forming the exact part from metal materials that work with existing components or detailed design specifications.

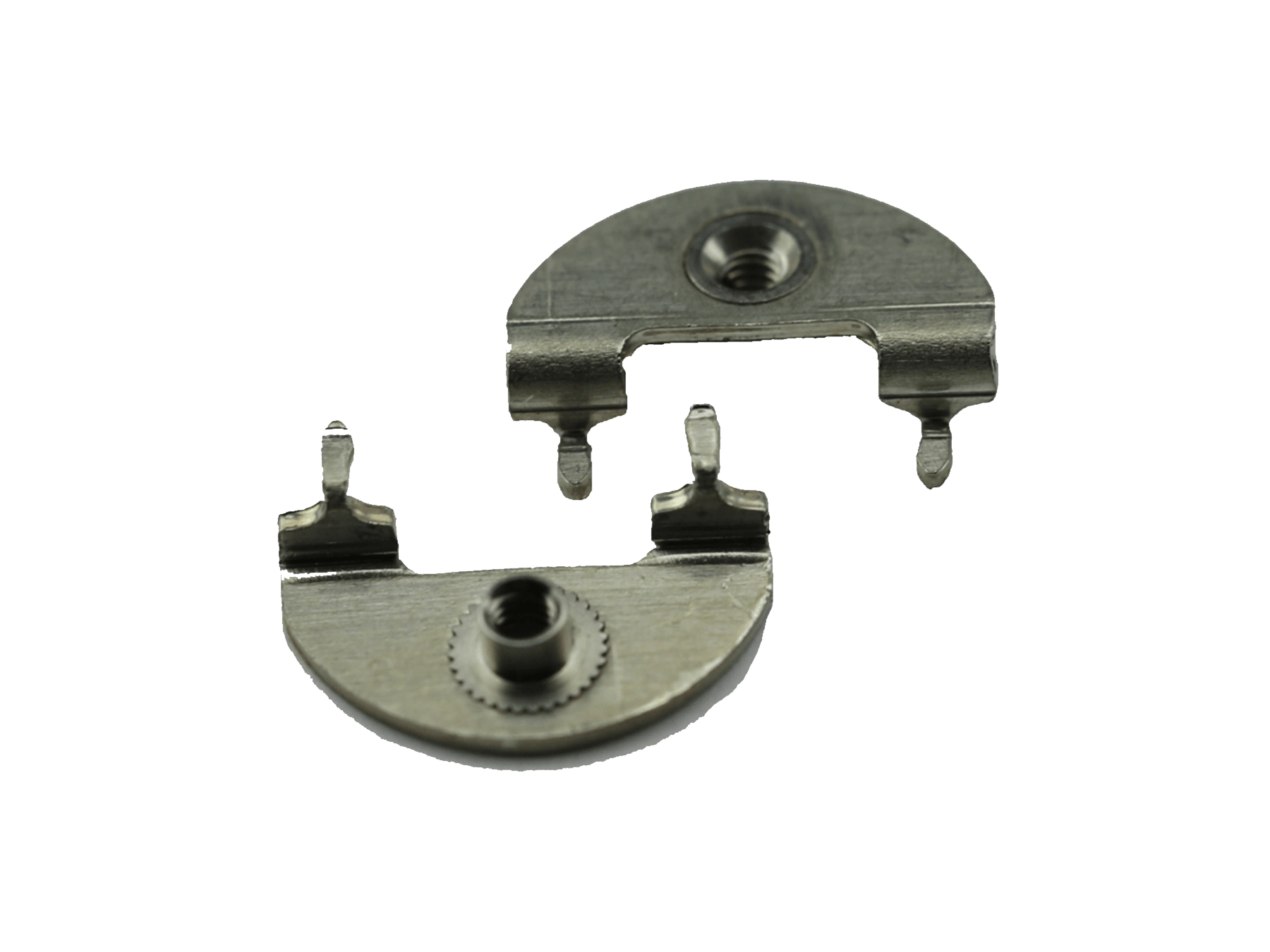

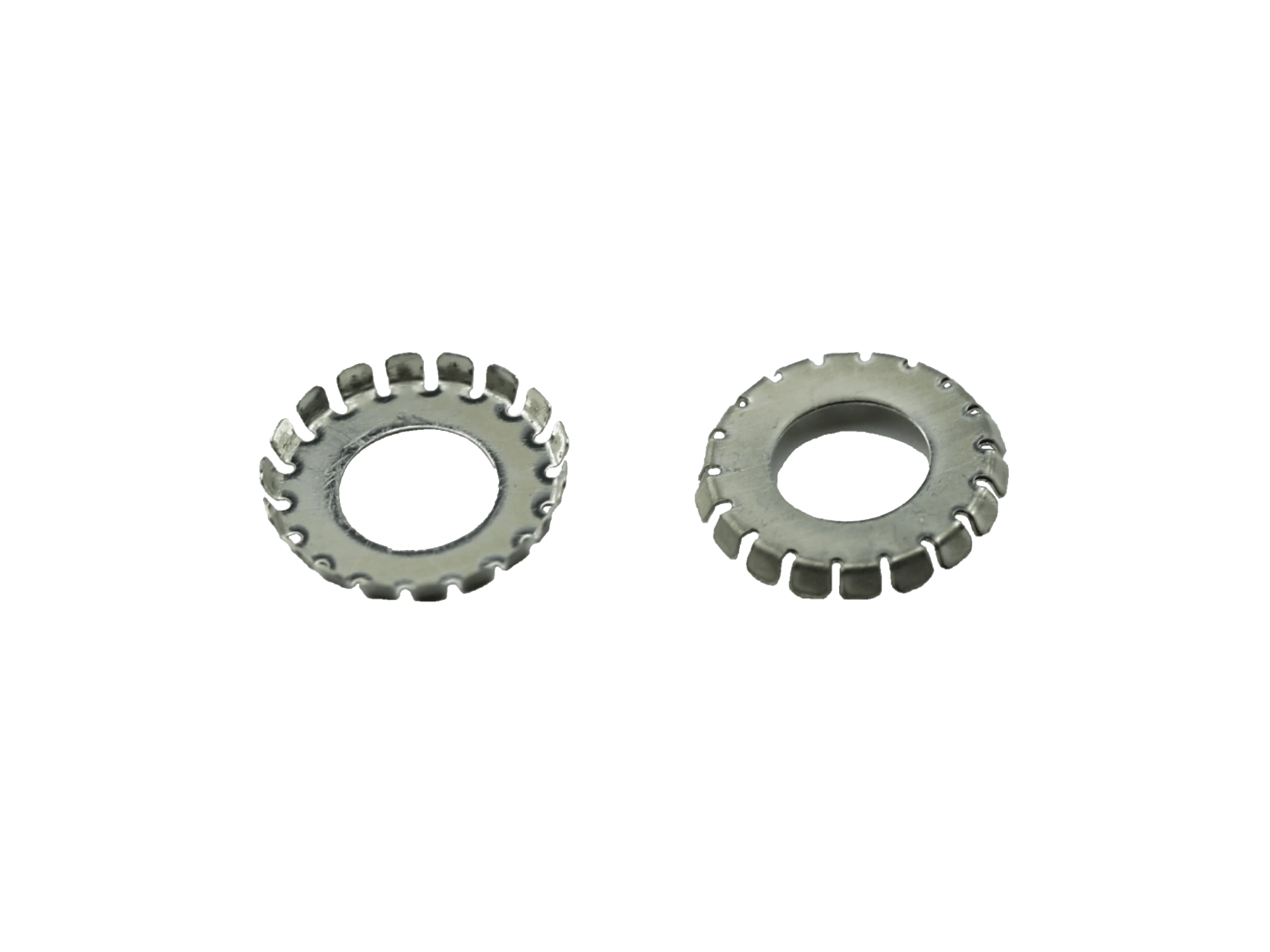

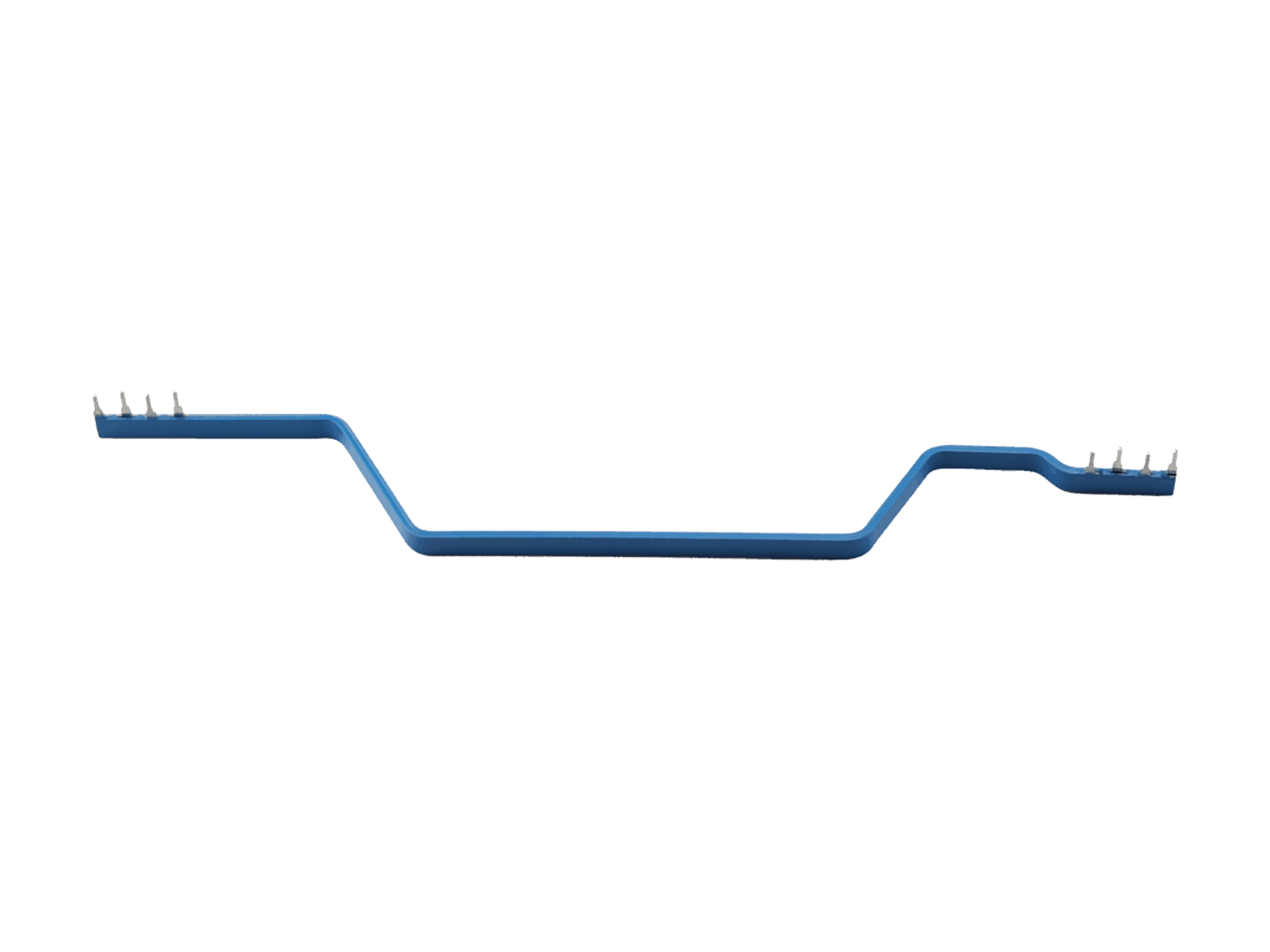

| Dimpling | A proprietary forming process developed at E-Fab used to ensure electrical contact is available on the part surface |

| RFI & EMI Shielding | Manufacture of materials into precise shields for use in highly sensitive applications |

| Waveguide Forming | Used in complex seamless structures to direct and control electromagnetic energy |

| Angle Forming | For times when maximum alloy strength is required for a part |

| Industries Served | Aerospace, Military, Defense, Energy, Fuel Cells, Medical, Microwave, Semiconductor, Telecommunications, Colleges, Secondary Schools, Federal Agencies, State Government, Agriculture, Automotive/Transportation/Mobility, Electronics, Instrumentation & Control Systems, Manufacturing, Technology |

| Materials Used | Copper, Beryllium Copper, Brass, Phosphor Bronze, Nickel, Nickel Silver, Nickel Iron, Steel, Stainless Steel, Spring Steels, Aluminum, Kovar, and other common and exotic materials |

E-Fab is a proud member of The Partner Companies group of specialty manufacturers. Our network shares experience, materials, capabilities, and expertise to serve the defense, aerospace, medical, telecommunications, semiconductor, and renewable energy industries.

If you need a capability that we do not offer at E-Fab, please let us know, and we will connect you with a TPC company that can help.

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

1009 Timothy Drive

San Jose, CA 95133

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us