Specialized applications often require rigid circuit board stiffeners, copper bus bars with high current carrying capacity, large ground planes, or other advanced circuits. E-Fab, trusted by leading companies across a variety of industries, is renowned for producing stiffeners and busbars used in printed circuit boards that can assist in engineering and manufacturing lead-free certified Printed Circuit Boards (PCBs), multilayers, and backplanes for multiple end-use applications.

As a leading formed busbar fabricator, we’re your go-to custom manufacturer for all your custom copper bus bar needs, from low-volume production to high-volume, low-cost runs.

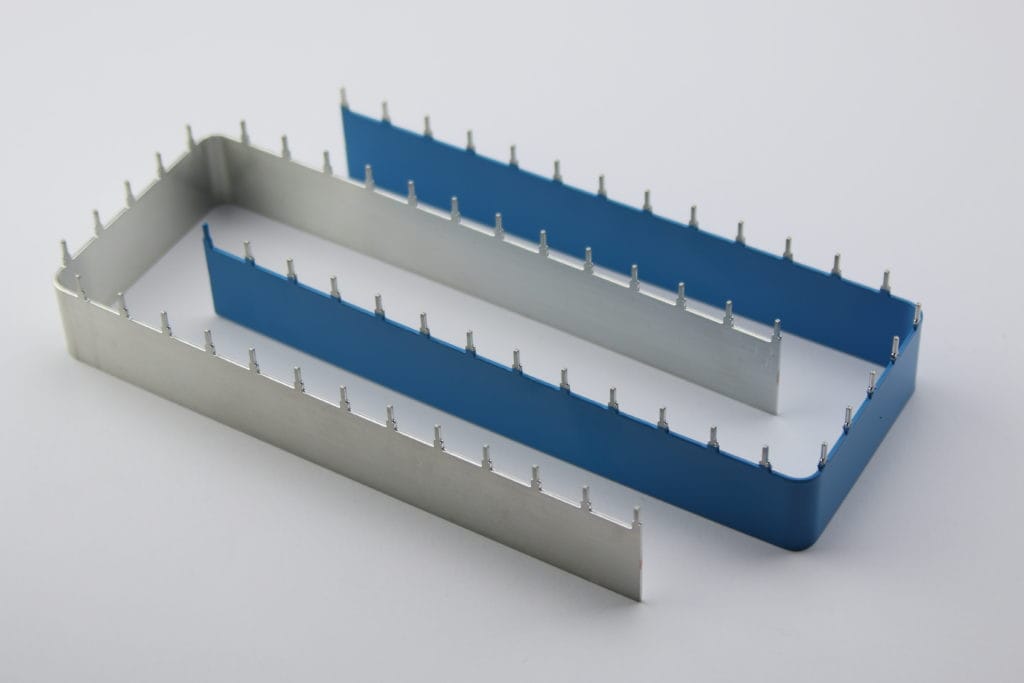

Leaders in photochemical etching (PCE) (also known as photochemical machining or chemical blanking), E-Fab manufactures precision stiffeners and custom bus bars that are the highest quality, direct replacements for the old Circuit Components, Inc. (CCI) type. Say goodbye to short circuits with high-quality busbars and stiffeners manufactured from copper, copper alloy, and brass. Our cutting-edge precision metal manufacturing techniques ensure that our busbars and stiffeners are not only RoHS and ISO 9001 compliant, meeting stringent environmental standards, but also benefit from a durable epoxy coating that enhances both their longevity and electrical performance.

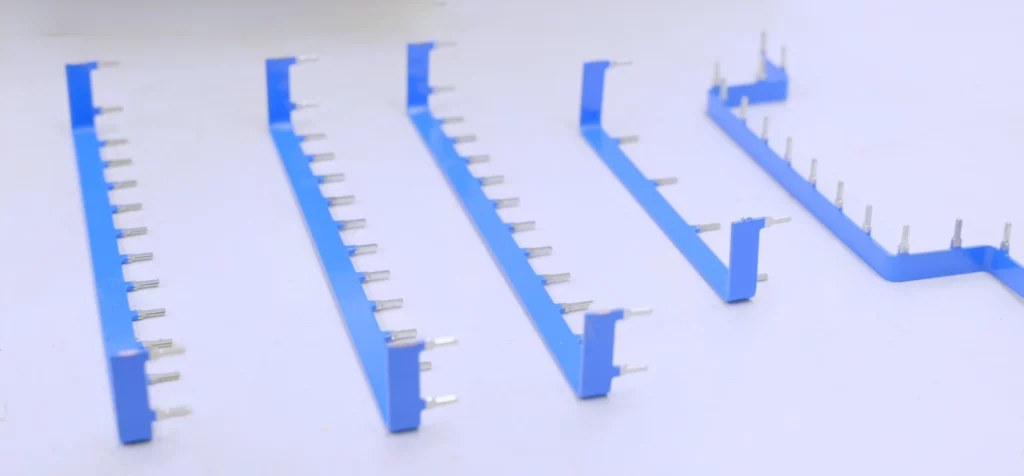

Fully customizable, our bus bars and stiffeners are available in many sizes, shapes, materials, and finishes depending on the specifications, delivering your complete control over board thickness. As a leading supplier of custom busbars, we work with various materials to provide precise, accurate bus bars for application in almost any industry.

PCB Stiffeners keep PC boards flat, straight, and rigid. They require very little space and allow for the close proximity of other on-board components. Generally, a stiffener is used to rigidize the PCB during and after assembly. It protects the board from cracks on solder joints and traces and helps decrease vibration and shock damage.

E-Fab manufactures stiffeners in various lengths, any number of pins, and numerous selections of pin grid patterns. We also have double-layer and ‘L’ shaped circuit board stiffeners available.

A busbar is a dielectrically coated stiffener with the added benefit of carrying ground and power distribution up to 128 amps, which eliminates the need for heavy traces. The use of busbars fabricated at E-Fab allows for efficient current management while maintaining a compact design.

In electrical power distribution, a busbar (also spelled bus bar, buss bar, or busbar) is a metallic strip or bar that conducts electricity within various systems like distribution boards, circuit boards, battery banks, power supply units, or other electrical apparatus. Bus bars, often crafted from copper or brass, are preferred for their high electrical conductivity, which is essential for efficient energy transfer.

The primary purpose of a bus bar is to facilitate the conduction of a high current, much more than standard power and ground traces can handle. This electrical conducting bus achieves its impressive energy management capability due to its dielectric powder coating, which supports a hipot of up to 2000 volts.

Features. Circuit boards can be designed around various types of busbar features, such as custom-designed pinning configurations, including different widths of the pins or connector tabs for high current distributions onboard a PCB. Some application requirements are ideal for heat sinking or mounting other hardware devices, electronic components, or connectors to the circuit board. All busbar features are customizable by E-Fab, including:

E-Fab manufactures aluminum busbars in addition to two or more layers and multi-layer busbars, all tailored to precise specifications. These 2-layer busbars are versatile and can be used on panel boards, busway enclosures, power supplies, or other power distribution applications to manage both power(s) and ground simultaneously, even in electrical switchyards handling high currents.

The 2-layer busbar functions as a multilayer component, with two conducting copper layers separated by an insulating layer. These copper layers are manufactured with a staggered pin configuration (custom configurations are also available), allowing every other pin to serve as power or ground. The advantage of using a 2-layer busbar on a circuit board is that it combines the advanced features of a stiffener with the addition of extra power and ground buses in one compact, efficient design.

View E-Fab’s Proprietary Stiffener drawing page.

Circuit boards and printed circuit boards (PCBs) hold the brains of the world’s most important technology.

A busbar is a metallic strip or bar, typically manufactured in copper or brass, that conducts electricity within a distribution board, circuit board, battery bank, power supply unit, or other electrical apparatuses. Engineers design these parts to conduct a substantial current of electricity, more than can be provided by standard circuit board traces.

Quick note: You might see other places spell busbars differently, including bus bar, BusBar, or busbar. We spell it busbar.

A stiffener is a metal or material sheet attached to a PCB to strengthen the board and increase rigidity. Stiffeners are important when circuit boards are used in stressful situations.

Busbars can serve the dual purpose of being a conducting bus and providing structural integrity to a circuit board. Stiffeners are not recommended as buses since brass is said to have 28% of the International Annealed Copper Standard (IACS) (Copper Development Association Inc.).

As a leading formed busbar fabricator, E-Fab’s manufactured stiffeners and busbars will enable you to increase PCB yields, reliability, and longevity of your circuit boards. They are also cost savers; mounting rivets and installation screws are not required for circuit board assembly.

Additional advantages of stiffeners and busbars include:

Increasing the rigidity of modern circuit boards is more important than ever. The adaptation of lead-free solder to meet the Restriction of Hazardous Substances Directive (RoHS) requires increased temperatures in wave soldering, and the required use of different metals and alloys places significant strain on the circuit boards.

Keeping circuit boards and backplanes flat through the manufacturing and assembly process is critical for producing high-quality and reliable boards. There is, however, another reason for using PCB stiffeners. Consider the natural elements of thermal expansion and contraction through hot and cold operating temperatures, the warming and cooling cycles when a circuit board is in use, and the normal vibration factors during usage. These operating conditions can cause early board failures resulting from cracked traces and cold solder joints developing at the circuit components’ connections. These are typical applications where the PCB stiffener solution should be applied.

Using stiffeners and busbars gives strength and rigidity to applications intended for use in unforgiving environments. Other applications that benefit from these products include power and/or ground circuits on PCBs and power supply circuits. E-Fab has served customers in industries such as:

Copper bus bars are unsung heroes of electrical connectivity, powering, and optimizing operations across a wide range of leading industries. This is due mainly to their incredible versatility, which makes them perfect for demanding applications in even the harshest conditions.

From aerospace and defense to technology, semiconductors, and medical, critical electrical systems rely on these essential components to ensure seamless transmission of power and data.

Discover the versatile applications of copper bus bars across various industries.

E-Fab’s busbars are designed with two conducting copper layers separated by an insulation layer, making it a multilayer solution. The copper layers are designed and manufactured with a staggered pin configuration (custom configurations are also available) so that every other pin is power and ground.

The two-layer busbar fabricated at E-Fab offers customers the advantages of a PCB stiffener, plus extra power and ground busses rolled into one space-saving design.

Depending on customer requirements and part applications, E-Fab manufactures its busbars and stiffeners uncoated or coated with epoxy, depending on customer requirements and part applications.

Find out how to Choose the Right Busbar Manufacturer

We’ve been producing busbars and stiffeners since our earliest days, producing these parts for the telecommunications, defense, medical, and electronics industries.

At E-Fab, we are well-versed in working with the two main metals used for busbars and stiffeners: copper and brass.

Plus, our skilled team guides clients through a project toward the finest solution that precisely meets their needs.

Our areas of expertise include

E-Fab uses industry-leading equipment and is an ISO 9001:2015 certified facility. Our innovative processes and expert staff ensure that every component we fabricate is of the highest quality. Learn more about our photochemical etching services here.

We have the resources and capabilities to take on challenging projects. As a trusted custom manufacturer, our engineering team doesn’t stop until the parts and services meet your specifications and perform as expected.

Our fabrication experience and ability to think creatively have made E-Fab a trusted partner to our customers and a leading custom copper busbar supplier. With unmatched capabilities, contact us today to request a quote for your project.

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

1009 Timothy Drive

San Jose, CA 95133

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us