The advantages of nickel — including corrosion and thermal resistance, strength, and durability — and the variety of nickel alloys make it a metal that’s suitable for many industries and applications.

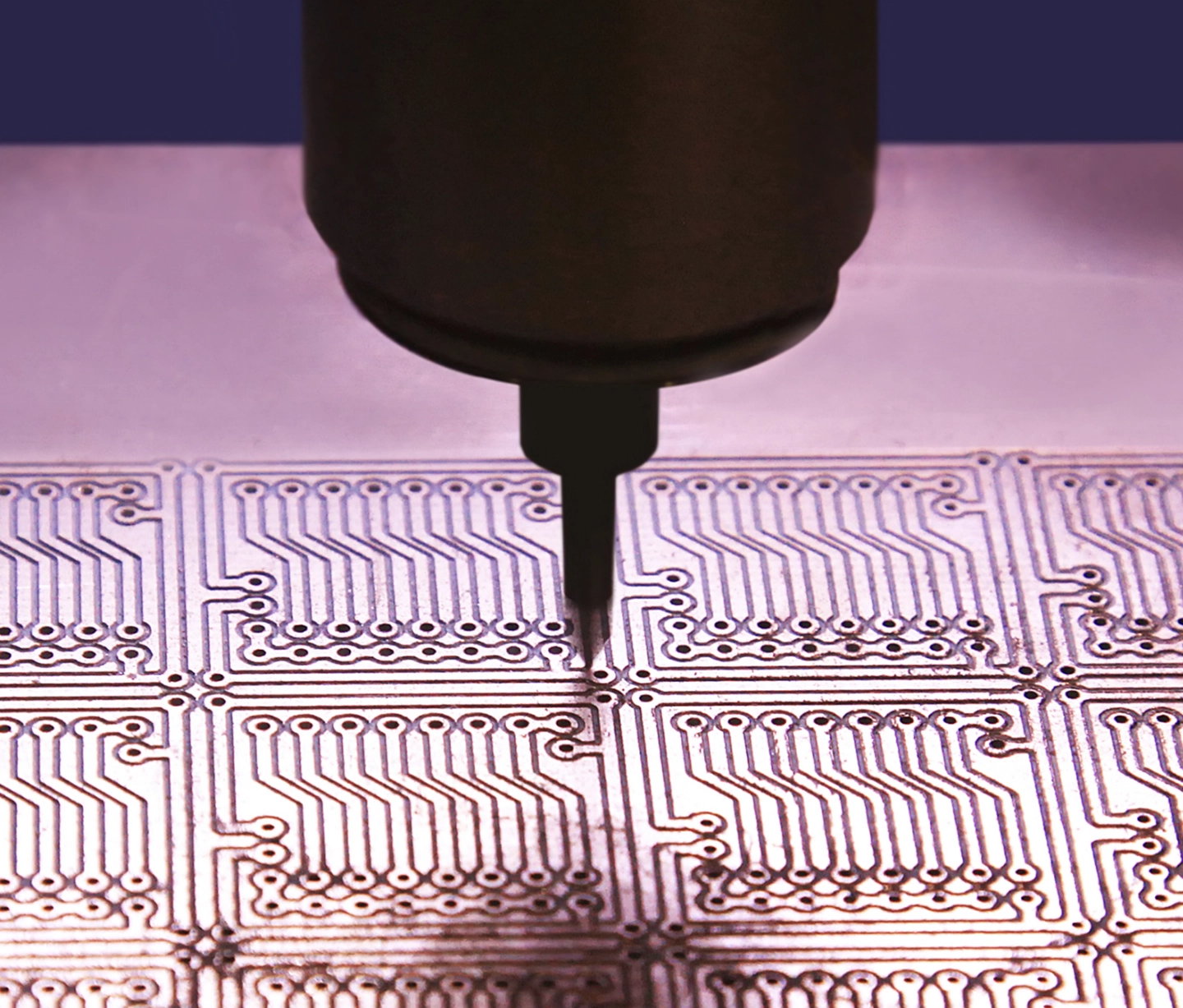

We leverage nickel’s flexibility, shielding properties, and corrosion resistance while manufacturing precision parts used in aerospace, electronics, communications, and defense industries.

We welcome your questions about how to use nickel for your parts.