Readily available, easy to machine, and affordable, copper is a popular metal for precision manufacturing. Malleable enough to be used in a range of manufacturing processes, copper is used to create accurate, reliable parts for some of the world’s leading industries.

E-Fab boasts extensive experience in copper manufacturing, producing a wide variety of precision copper parts, including flex circuit parts, stiffeners, busbars, and micro bumps. As a leading supplier of precision copper parts, we’re the trusted partner for clients in the electronics, defense, industrial, technology, and communications industries.

Discover the difference copper can make for your precision parts.

The Unique Properties of Copper

Copper’s unique chemical and physical properties make it an ideal candidate for photochemical etching. Its exceptional conductivity and malleability make it a versatile material for intricate processes like the chemical etching copper process. Its inherent resistance to corrosion ensures that the final etched copper components maintain durability and longevity. At the same time, its moderate atomic weight and stability enable the creation of detailed and finely defined features during the copper etching process.

These properties, coupled with its cost-effectiveness and wide availability, make copper a preferred choice for photochemical etching, enabling the production of intricate and high-precision metal components used in various industries, from electronics to aerospace.

The Common Applications of Copper

With the ability to produce intricate and high-precision metal components, photochemical etching of copper is widely used for key applications across diverse industries. This versatile and precise manufacturing process is especially valuable for applications where intricacy, durability, and reliability are paramount.

In the electronics industry, chemical etching copper is commonly used to manufacture intricate circuit boards, ensuring precision in the placement of electrical components. Chemical etching copper fabricates heat exchangers, sensor components, and other complex parts for the aerospace industry. In the medical field, copper etching is instrumental in producing precise components for devices like stents and surgical instruments. The automotive sector leverages copper etching for manufacturing complex parts like fuel injector nozzles and sensors.

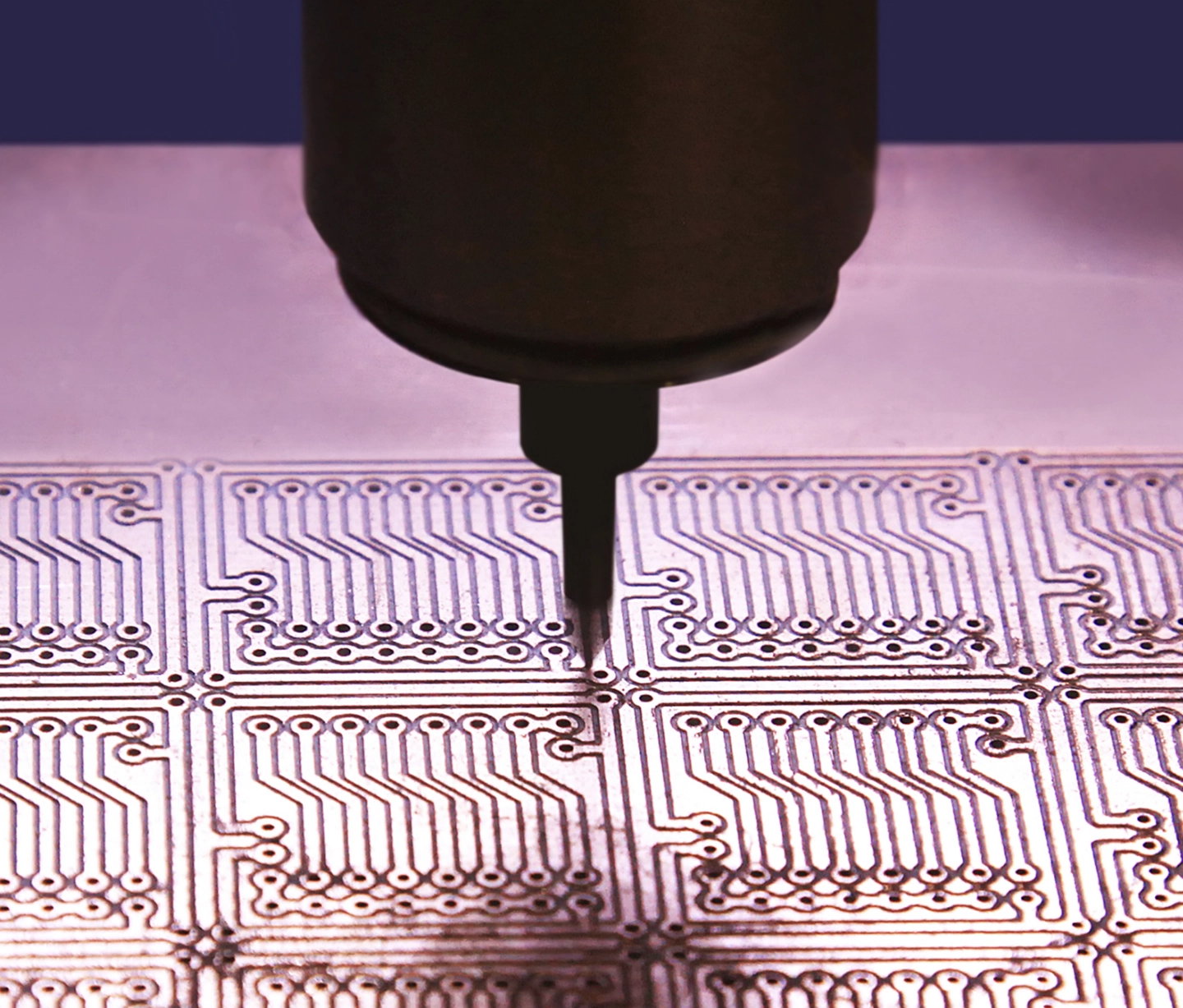

Photochemical Etching – How To Etch Copper

The photochemical etching of copper process is a sophisticated technique used to consistently produce intricate and high-precision metal components.

The process typically begins with a copper sheet or copper alloy coated with a photosensitive material. A detailed photomask is then applied to the material, protecting specific areas from exposure to light. The exposed portions undergo a chemical reaction, making them susceptible to an etching solution. Acid etching, commonly utilizing ferric chloride as a commonly used etchant, is then employed to selectively remove the unprotected copper, leaving intricately defined patterns and features. The final step is to rinse in water. This process allows for producing finely detailed components with high precision and repeatability.

Why Choose Copper: The Advantages of Etched Copper

Copper’s numerous benefits make it a preferred metal for engineers and designers. In addition to the material’s conductivity and flexibility, copper is easy to work with while manufacturing precision parts, will accept nearly any finish, and conforming coatings can provide anti-oxidation protection for PCB applications.

The precision achievable through photochemical etching copper is unparalleled, allowing for the creation of intricate and finely detailed components with exceptional accuracy. Copper’s inherent conductivity makes it an ideal choice for applications in electronics, where precise circuitry is paramount. Copper’s durability ensures the longevity of etched components, making them resilient in various operating conditions.

Compared to other materials, such as aluminum and steel, copper’s combination of precision, conductivity, and durability positions it as a standout choice, particularly for applications requiring intricate designs and high performance.