Optimize thermal management with E-Fab, Inc.’s custom-etched heat sinks engineered for precision, performance, and reliability in compact, high-power systems.

E-Fab, Inc. is a certified precision etching manufacturer serving the heat sink and thermal management industry, committed to quality, industry standards, and exceptional customer service.

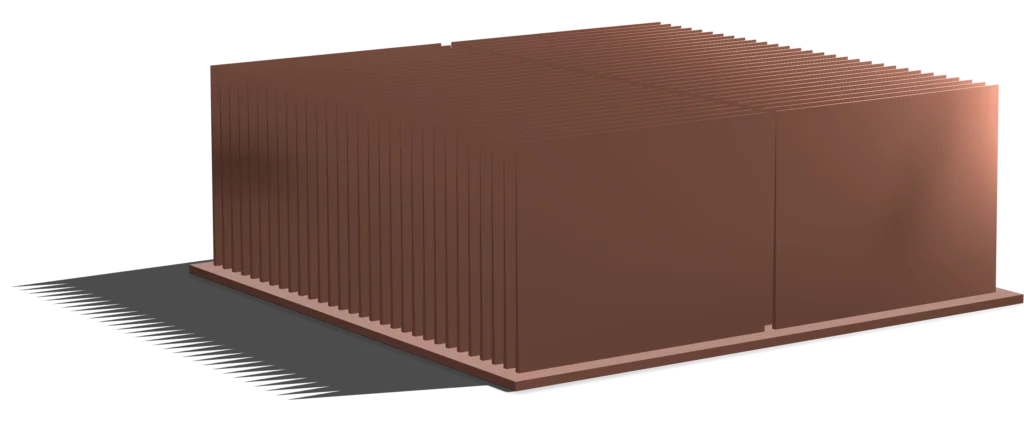

Modern electronic devices generate significant heat in increasingly compact footprints. Managing that thermal load is essential to maintaining reliability and performance. Heat sinks work by dissipating heat away from sensitive components, making sure they remain properly cooled and functional. E-Fab manufactures custom heatsink and thermal spreader solutions using advanced photochemical etching, enabling complex geometries, ultra-thin profiles, and stress-free results unmatched by traditional machining or stamping. After photochemical etching, heat sinks can be finished with anodizing or powder coating to enhance durability and corrosion resistance. Extruded or etched heat sinks are cut to the required dimensions as part of the manufacturing process. E-Fab has the depth of expertise in custom heatsink design and manufacturing to address complex thermal management needs. Our team can produce custom heatsinks efficiently and at various volumes using advanced photochemical etching.

E-Fab offers extensive customization options, including the ability to create heat sinks in a variety of shapes and with features such as holes for mounting or assembly, ensuring solutions are tailored to each application.

With decades of experience serving aerospace, defense, semiconductor, energy, and industrial sectors, E-Fab helps design engineers achieve high-density, lightweight thermal solutions with total control over design and performance by selecting materials with the needed properties for each application.

E-Fab is dedicated to thorough validation and quality assurance processes before shipping products to customers, making heat sinks with complex shapes and features to meet demanding requirements.

Heatsinks are critical components that transfer thermal energy away from heat-generating devices such as power transistors, laser diodes, and RF modules to prevent overheating and ensure stable operation. Heatsinks are responsible for dissipating heat away from the heat source to maintain safe operating temperatures. A wide range of heatsinks, including forged, machined, and skived copper heatsinks, are available to provide custom solutions for electronic cooling.

Traditional extruded or stamped sinks often limit design freedom due to tooling constraints and material stress. By contrast, custom-etched heat sinks enable engineers to define fin geometry, spacing, and thickness precisely, optimizing heat transfer through conduction and convection while maintaining consistent flatness for superior thermal contact.

Key performance factors:

Effective thermal management is essential to the performance, reliability, and longevity of modern electronic devices, and engineers have a variety of cooling solutions available to address different levels of heat generation and environmental demands. Air cooling remains the most widely used method, relying on heat sinks and fans to channel heat away from sensitive components and disperse it into the surrounding air. Its appeal lies in its simplicity, affordability, and proven reliability across countless consumer and industrial applications.

For devices with higher thermal loads or demanding performance requirements, liquid cooling provides a more capable alternative. By circulating coolant through cold plates or micro-channel structures attached to heat-generating components, liquid cooling systems transfer heat more efficiently and maintain lower, more stable operating temperatures. Hybrid cooling solutions, which blend air and liquid-based methods, are often used in high-power, space-constrained, or mission-critical electronics to achieve both performance and system-level resilience.

Selecting the right thermal solution involves assessing a range of design factors, heat output, footprint, weight, environmental conditions, manufacturability, and long-term reliability. This is where E-Fab’s experience becomes especially valuable. With decades of expertise in precision fabrication, materials engineering, and thermal-focused design support, E-Fab is uniquely positioned to help customers evaluate, prototype, and deliver the ideal cooling approach. Their capabilities in producing complex metal structures, custom heat-spreading components, micro-features, and precision assemblies enable them to support everything from standard air-cooled designs to advanced liquid and hybrid systems.

Whether the goal is to optimize thermal performance, reduce system weight, or integrate cooling into a compact mechanical envelope, E-Fab provides end-to-end guidance and fabrication expertise. Their proven track record in managing complex thermal applications and program requirements ensures that customers receive robust, application-specific solutions that keep devices operating reliably, even in the most demanding environments.

E-Fab’s photochemical etching (PCE) process unlocks design possibilities impossible with machining, stamping, or traditional cutting methods. Unlike conventional cut techniques that are limited in complexity, etching allows for the creation of intricate and complex shapes with high precision. The process removes material chemically, producing burr-free, stress-free components with exacting detail and repeatability. E-Fab’s in-house shop capabilities enable rapid prototyping and production, supporting quick turnaround times for a variety of industries.

Etched heat sinks can also be further modified after the initial etching process to meet specific thermal or dimensional requirements, providing additional flexibility for custom applications. Photochemical etching offers extensive customization options, including the ability to engineer unique shapes and geometries tailored to specific device needs and applications.

Engineers can specify intricate fin arrays, optimized flow paths, and ultra-thin structures that improve cooling efficiency without adding bulk, critical in RF, power electronics, and miniaturized systems.

Different thermal challenges demand the right material, and E-Fab’s expertise covers a wide range of metals optimized for heat dissipation and mechanical stability. The choice of material and finish depends on the needed thermal and mechanical properties for each application. For example, finishing processes such as anodizing and powder coating can be applied to aluminum heat sinks to improve corrosion resistance and appearance.

Key Benefit:

Highest thermal conductivity for maximum heat transfer

Thermal Conductivity (approx.):

~400 W/m·K

Key Benefit:

Excellent conductivity with low weight

Thermal Conductivity (approx.):

~235 W/m·K

Key Benefit:

Controlled thermal expansion for hybrid assemblies

Thermal Conductivity (approx.):

—

Key Benefit:

Corrosion resistance where conductivity is secondary

Thermal Conductivity (approx.):

—

E-Fab fine-tunes etch chemistries, time, and temperature to each alloy, maintaining consistent thickness, edge quality, and surface finish, ensuring every component performs exactly as designed.

Heat sinks can be provided ready for integration or with optional treatments.

E-Fab partners with design engineers from concept through production, applying deep knowledge of Design for Manufacturability (DFM) to refine thermal solutions. E-Fab offers extensive customization options to ensure each heat sink design is complete and meets all customer requirements.

This collaborative process ensures optimized fin spacing, uniform contact surfaces, and predictable thermal resistance, critical for high-reliability electronic assemblies.

E-Fab’s precision-etched heat sinks and spreaders are ideal for applications where space, weight, and performance are tightly constrained, and where it is critical to keep devices properly cooled:

Engineers in these sectors rely on E-Fab’s process control and material expertise to achieve efficient, repeatable thermal performance without compromise, making sure electronics in these demanding applications remain reliable through effective thermal management and are consistently cooled.

When thermal performance, precision, and reliability matter, E-Fab delivers unmatched value. Our engineering team is ready to collaborate on your next design, from initial concept through production.

Order or purchase your custom heat sinks from E-Fab to ensure reliable cooling for your electronics. We also provide expert support for installation to guarantee optimal performance.

Click here to contact our engineers, download a data sheet, or learn more about how precision photochemical etching can transform your heat sink or thermal management solution.