Precision metal components for the Energy industry

Boasting unrivaled experience and an unwavering commitment to innovation, E-FAB has firmly positioned itself as a leader in etching precision custom components tailored to the unique requirements of critical energy applications.

Collaborating closely with our partners in both traditional and renewable energy industries, our dedicated team of engineers, manufacturers, and quality assurance experts consistently pushes the boundaries of what’s achievable.

No matter how complex the challenge, we’ve got the solution. It’s what’s made us the trusted choice for precision components for leading energy sector clients right across the globe.

Powering the Energy industry with Precision and Performance

Pioneers in precision, E-Fab has delivered precision metal components to top-tier industries within the energy sector for over four decades.

Working with collaboration at our core, we work closely with energy clients to conceptualize and fabricate precision components that meet the most rigorous tolerances and quality benchmarks, guaranteeing the structural robustness and dependability of the end products.

We specialize in energy-grade alloys, manufacturing exceptionally accurate and precise components built to perform in critical energy sector applications.

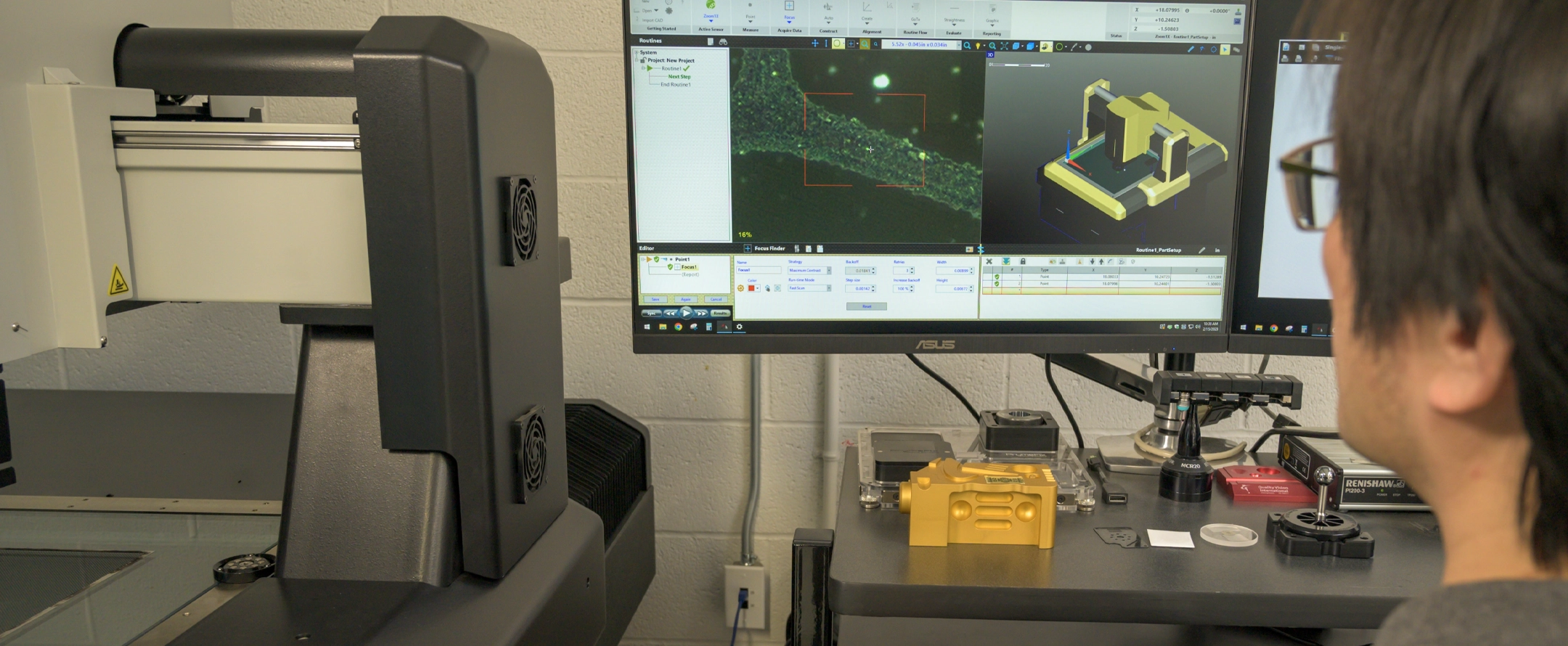

We’re proudly ISO9001:2015 certified, so you can rest assured knowing that every component we manufacture meets the highest quality standards and regulatory compliance.

Our Energy capabilities

E-FAB is powering the future of energy innovation by delivering a wide range of precision metal components designed specifically for energy applications. We’re committed to quality, producing the highest level of precision, and ensuring consistent performance for an industry where failure is never an option.

E-FAB provides a comprehensive range of precision components that include, but are not limited to:

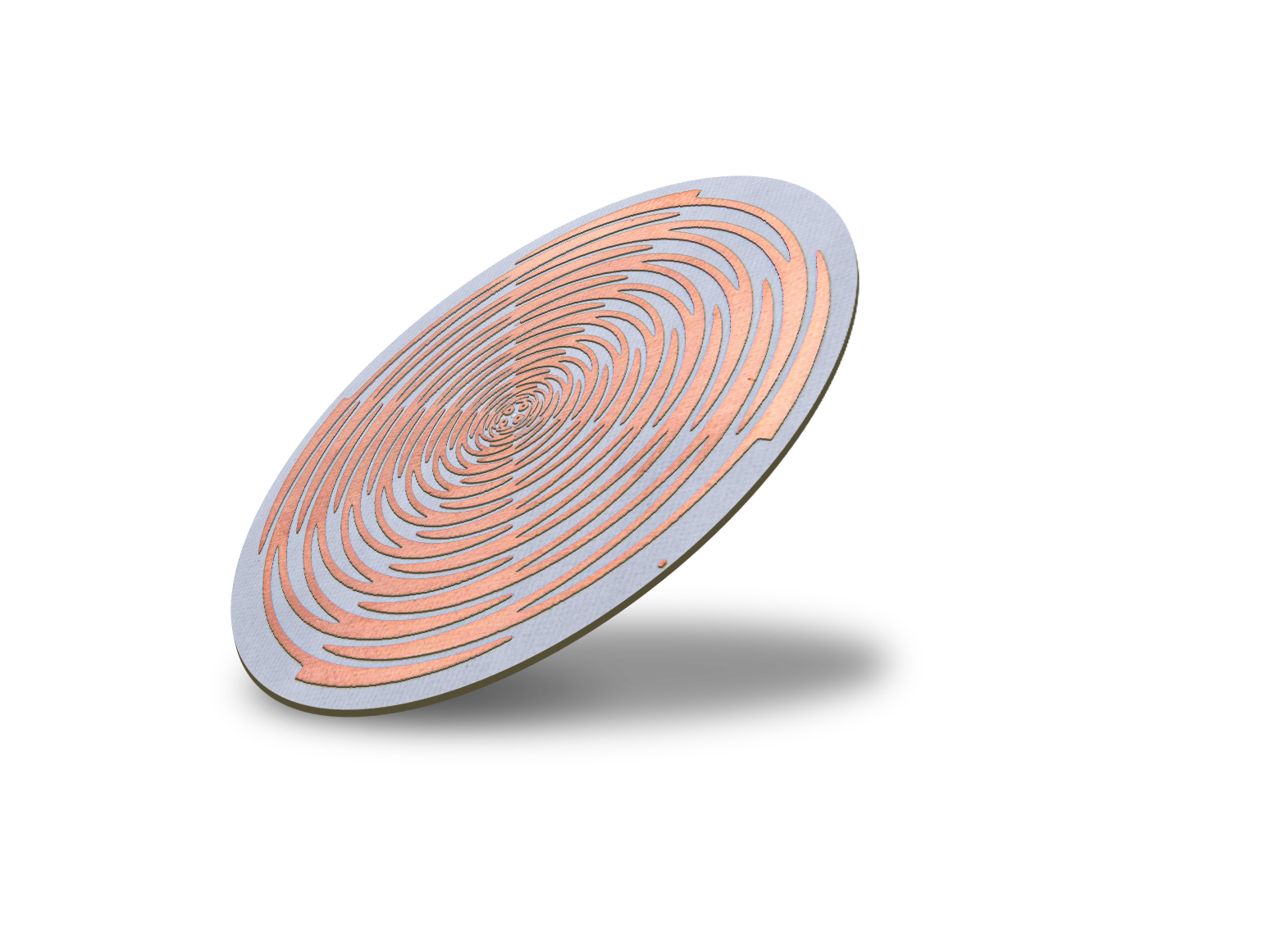

Energy Sensor Elements:

We design and manufacture specialized sensor elements that are critical for precisely monitoring and controlling various energy applications. These sensor elements are integral in renewable energy systems like solar and wind farms, ensuring optimal energy production and efficient resource management. The key benefit here is the enhanced capability to accurately monitor environmental conditions, improving energy production efficiency and reliability.

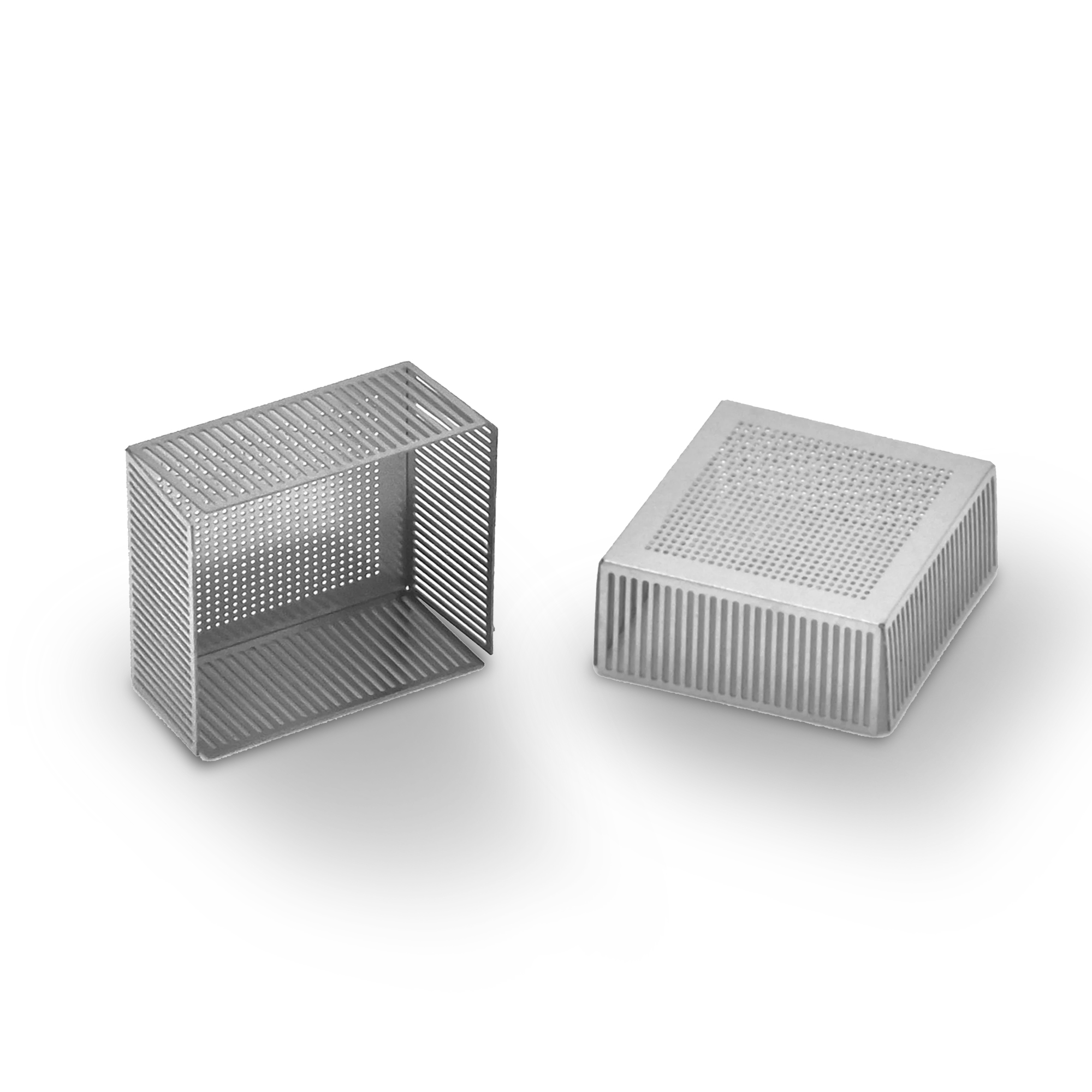

High-Precision Screens and Filters:

Our high-precision screens and filters play a crucial role in maintaining the integrity and efficiency of energy systems. They are particularly essential in applications such as biofuel production and water purification in hydroelectric plants. These components ensure the removal of impurities and the smooth operation of energy systems, thereby contributing to the longevity and reliability of these installations.

Energy Systems:

Specializing in intricate components, we ensure the seamless operation of energy systems and infrastructure. Our precision components are used in advanced applications such as smart grid technology and energy storage systems, supporting these sophisticated infrastructures. The benefit here is the enhanced system integration and performance, ensuring that energy distribution is both efficient and reliable.

Energy Sensors:

Our precision-engineered sensor components are designed to enhance the accuracy and reliability of energy monitoring and control devices. They find applications in residential and commercial renewable energy installations, where precise energy measurement and monitoring are crucial. These sensors contribute to better energy management and help in optimizing the performance of renewable energy systems.

Energy Instrumentation:

Our precision components play a vital role in energy instrumentation, ensuring precise measurements and effective control. These components are crucial in research institutions and for conducting energy efficiency studies, where accurate data collection and analysis are fundamental. The benefit is the assurance of high-quality, reliable data essential for developing and improving energy technologies.

Customized Energy Parts:

We offer customized solutions to address the unique needs of energy companies, ensuring optimal performance and efficiency. These tailor-made components are ideal for innovative renewable energy projects and experimental energy applications, where standard parts may not suffice. The advantage here is the ability to provide bespoke solutions that perfectly fit the specific requirements of a project, enhancing its overall performance and efficiency.

Miniaturized Parts for Energy Technology:

Excelling in the production of compact yet highly effective components, we cater to the needs of cutting-edge energy technology. These miniaturized parts are perfect for portable solar devices and small-scale wind energy solutions, where space efficiency and high functionality are paramount. The benefit of these components lies in their ability to deliver high performance in a compact form, making them ideal for innovative, space-conscious energy applications.

You can also choose from a wide range of general, value-added, and finishing options tailored to the unique requirements of your energy application. These include:

Rapid prototyping: Fast-track the development and testing of new energy devices and components.

Chemical blanking: Ensure optimal performance through precision cutting and material shaping.

Plating & Finishing: Enhance component durability and resistance to harsh environmental conditions.

High-Frequency Laminates Processing: Meet the specific needs of high-frequency energy applications.

Bonding: Ensure secure connections and seamless integration.

Forming: Create components that fit seamlessly into energy systems.

Blending Collaboration with Innovation

What makes E-FAB the premier choice for precision metal etching in the ever-evolving energy sector? It’s our unique approach. Seamlessly blending innovation and collaboration, we work closely with our energy partners to deliver innovative, customized solutions tailored to the unique demands of this vital sector.

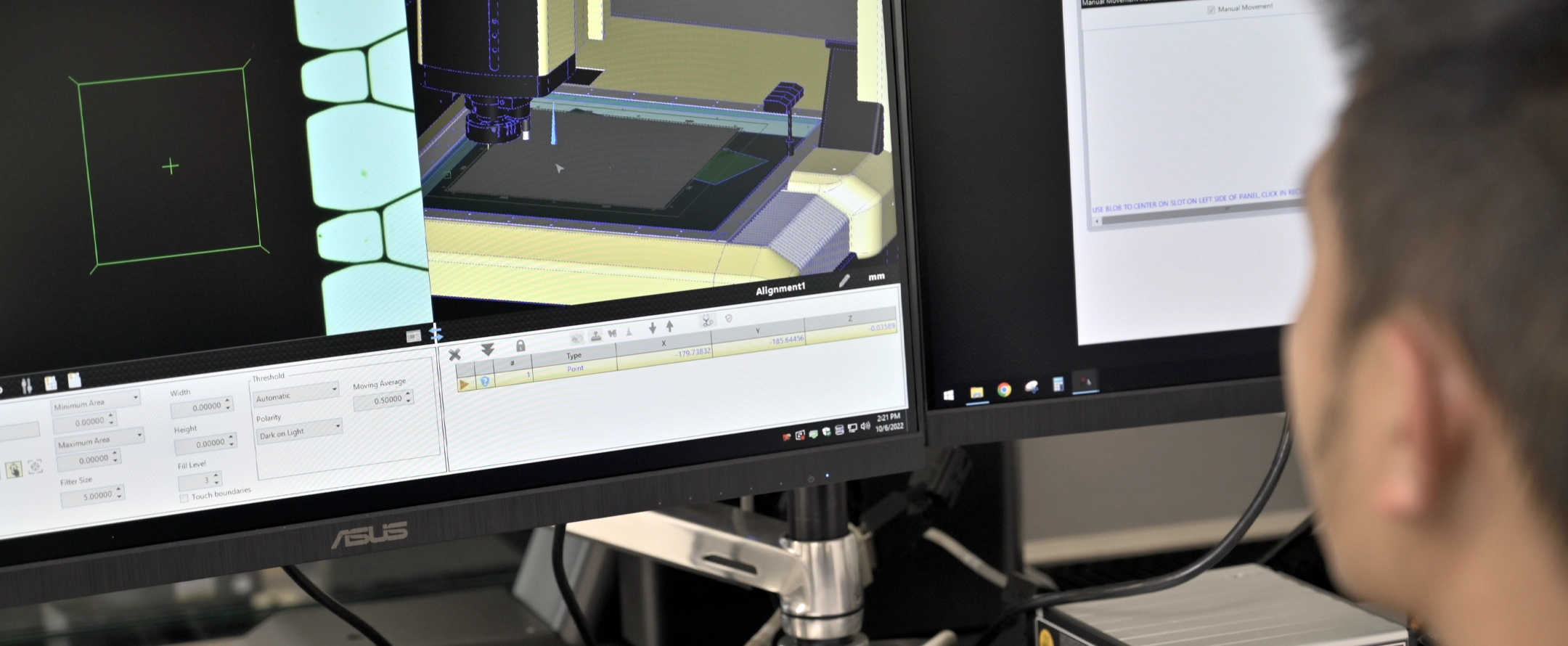

We don’t just meet industry standards; we exceed them, consistently investing in cutting-edge technology, including direct imaging printers, guaranteeing unmatched accuracy and precision that will stand up in even the most challenging energy applications.

With an unwavering commitment to excellence, we lead the way in energy etching services, delivering components that drive innovation and reliability in this dynamic industry.

Contact Our Energy Experts Today

As specialists in precision components for a wide range of energy applications, the team at E-FAB can deliver the highest level of quality and reliability for your energy project.

For precision and innovation in energy fabrication services, talk to us today.