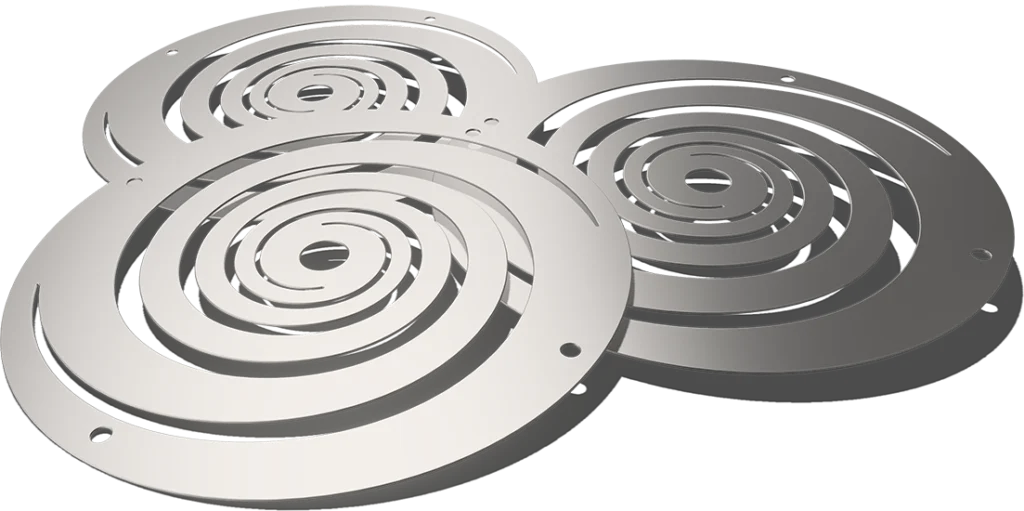

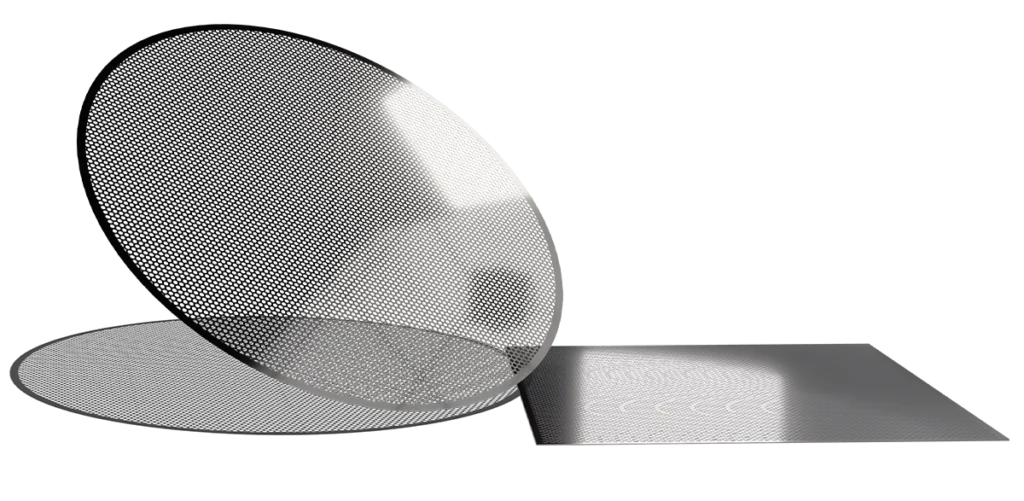

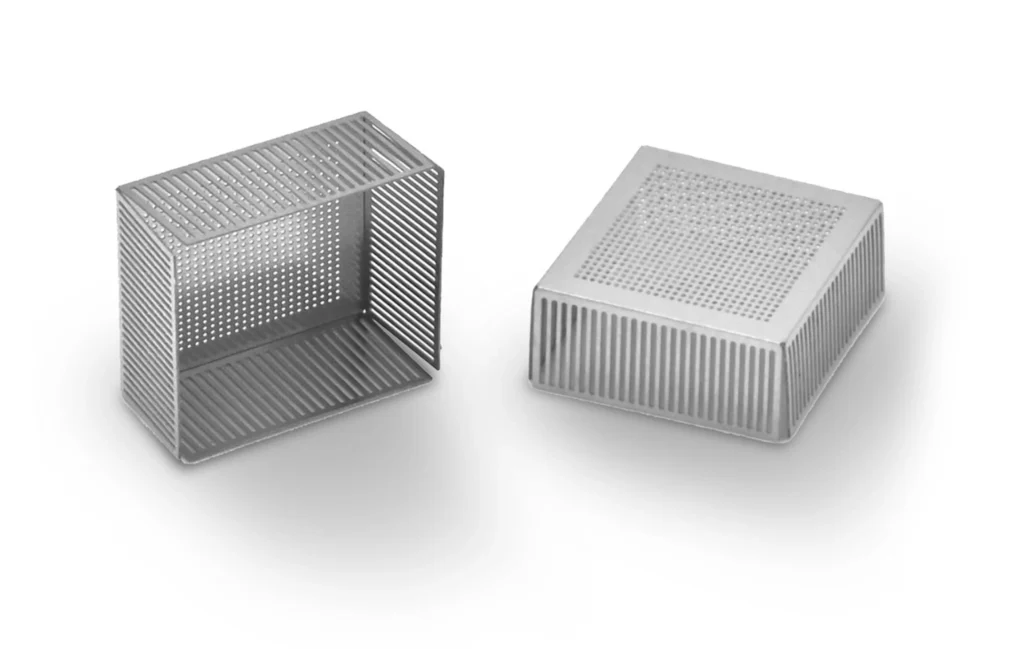

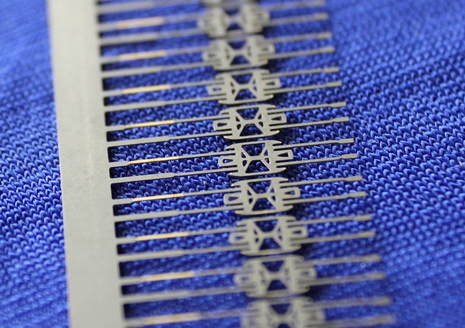

E-Fab’s photochemical etching process produces highly precise products and intricate parts without mechanical stress, burrs, or heat distortion. Using photoresist imaging and chemical etchants, E-Fab creates complex geometries with exceptional accuracy and repeatability.

Material selection is critical to the performance and reliability of the etched part, and E-Fab has extensive experience working with a wide range of metals, such as stainless steel, copper, brass, nickel, titanium, and specialty alloys, ensuring optimal durability and functionality for each application.

With expert engineering support from concept to production, E-Fab helps customers choose the right materials and optimize designs, delivering high-performance photo-etched parts that meet exacting standards.

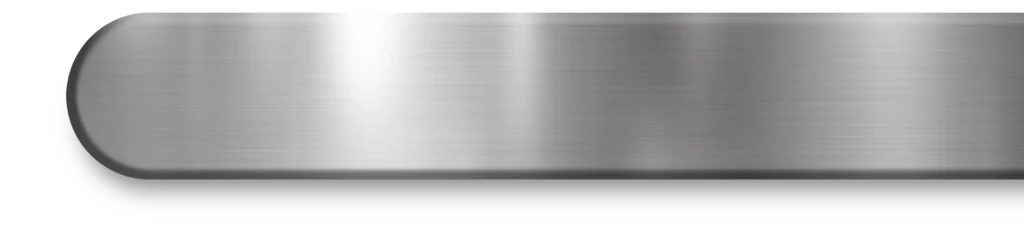

Type: 301, 304, 316 + More

Thickness Range: Min. 0.001″, Max. 0.050″

Performance Metrics: Formability

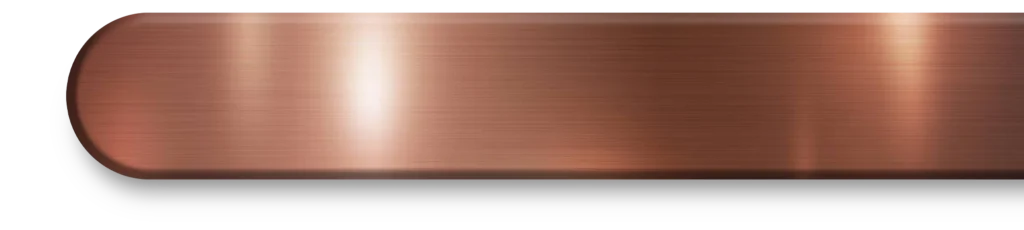

Type: C110, Brass, Bronze, + More

Thickness Range: Min. 0.0005″, max. 0.063”

Performance Metrics: High conductivity

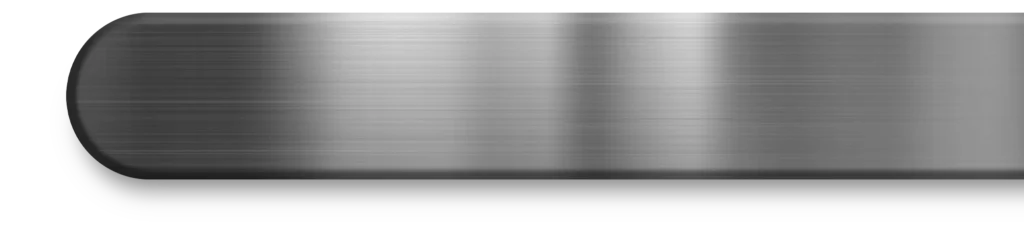

Type: Ni200, Invar, Monel + More

Thickness Range: Min. 0.001”, max. 0.040”

Performance Metrics: Thermal Durability and High corrosion resistance

Type: Ti-6Al-4V / Ti-6-2-4-6

Thickness Range: Min. 0.001”, max 0.040”

Performance Metrics: Superior Strength and Biocompatible, High corrosion resistance

Type: Molybdenum, Tungsten, + More

Thickness Range: Min. 0.001”, max 0.040”

Performance Metrics: Thermal and Electrical Performance

Material selection plays a critical role in determining the rate of success when it comes to photochemical etching, E-Fab understands the key areas to consider from edge quality, feature intricacy and most importantly, dimensional accuracy. Each material has a unique response to the etching process based on the metallurgy, hardness and reaction to various etchants.

At E-Fab, we stand behind the products we produce and the services we provide to our clients. This starts with the materials we source, with our CMRT compliance certification for sourcing materials, to our commitment to quality service. Along with that, we’ve created a reliable and robust network of suppliers both locally and nationally to support the services we provide to clients, and we maintain our quality throughout and strictly adhere to our ISO9001:2015 certification.

At E-Fab, the real thing that sets us apart is our engineering team, they’re dedicated to helping you get the most out of your photo-etch components. Our engineers work closely with you to understand your application, recommend the right materials, optimize your design for performance, precision, and cost-efficiency, and overall provide you with a best-fit solution.

As a premier supplier of photo-etched material processing, E-Fab combines advanced technology with personalized engineering support to deliver high-quality, reliable components across industries. Whether you’re developing a prototype or scaling up for production, our experts provide guidance on tolerances, edge quality, and manufacturability, ensuring your etched products meet your exact requirements.

About Our Aluminum Photochemical Etching Capabilities

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

1009 Timothy Drive

San Jose, CA 95133

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us