Precision-Crafted, High-Performance Etched Aluminum Components

1100 1145 1235 2024 3003 4057 5051 5052 6061 6063 7075

Call us to discuss which aluminum alloy is right for your part.

Aluminum is one of the most versatile and widely used metals in modern manufacturing, prized for its lightweight nature, high strength-to-weight ratio, corrosion resistance, and excellent electrical conductivity. As one of the primary strong but lightweight materials used in industry, aluminum is essential for applications where minimizing weight without sacrificing strength is critical. These properties make it an ideal choice as aluminum alloys are engineered to meet the demanding performance standards of today’s industries, and their response to chemical etching, particularly photochemical machining (PCM), varies based on composition and alloy series. Understanding these differences is essential for producing high-quality aluminum components with the precision and reliability required in sectors like aerospace, automotive, electronics, and medical devices.

Each aluminum alloy brings a unique blend of mechanical strength, electrical conductivity, and corrosion resistance, influencing how it behaves during the etching process. By tailoring the approach to each alloy’s characteristics, E-Fab can produce lightweight, high-strength aluminum parts that meet tight tolerances and deliver consistent, high-performance results.

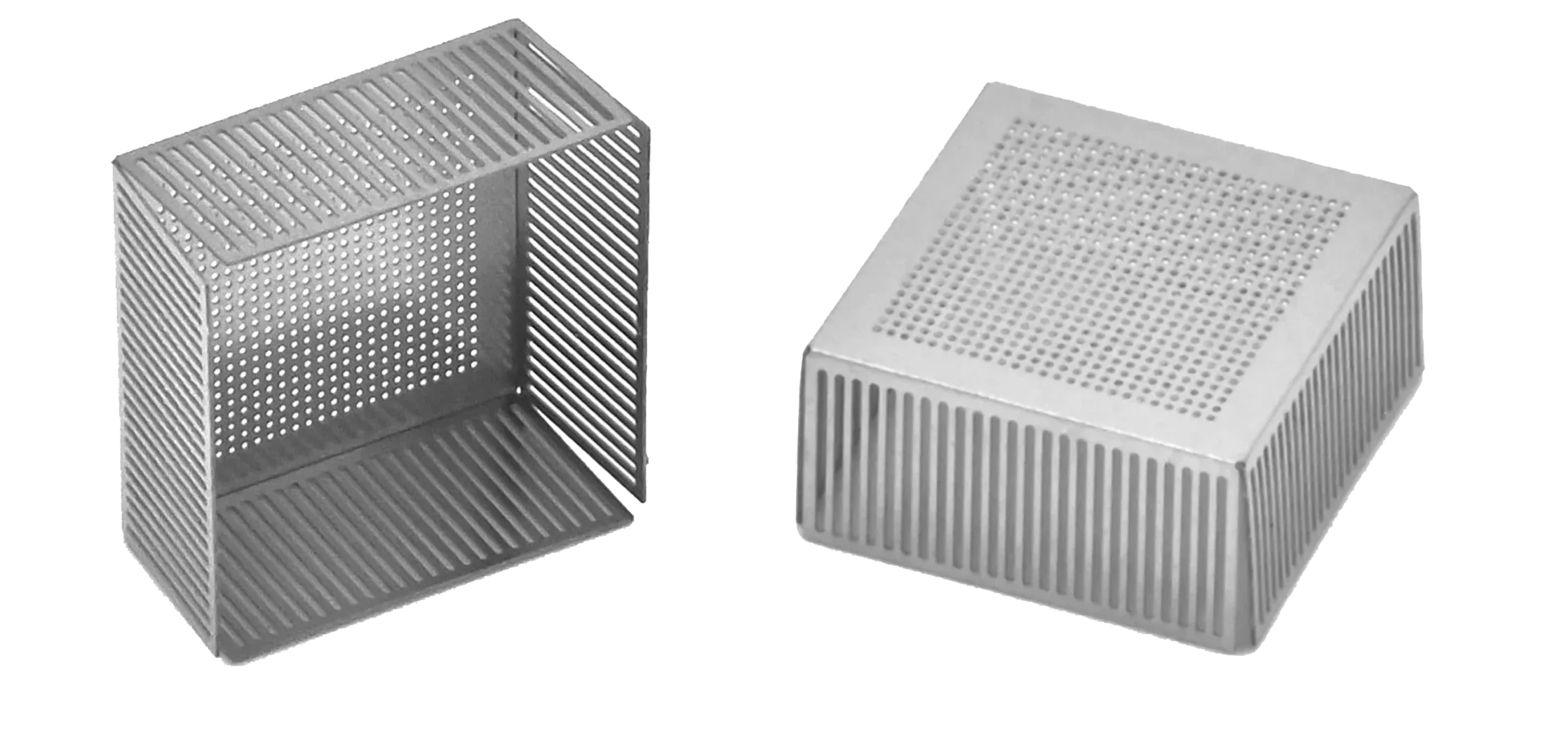

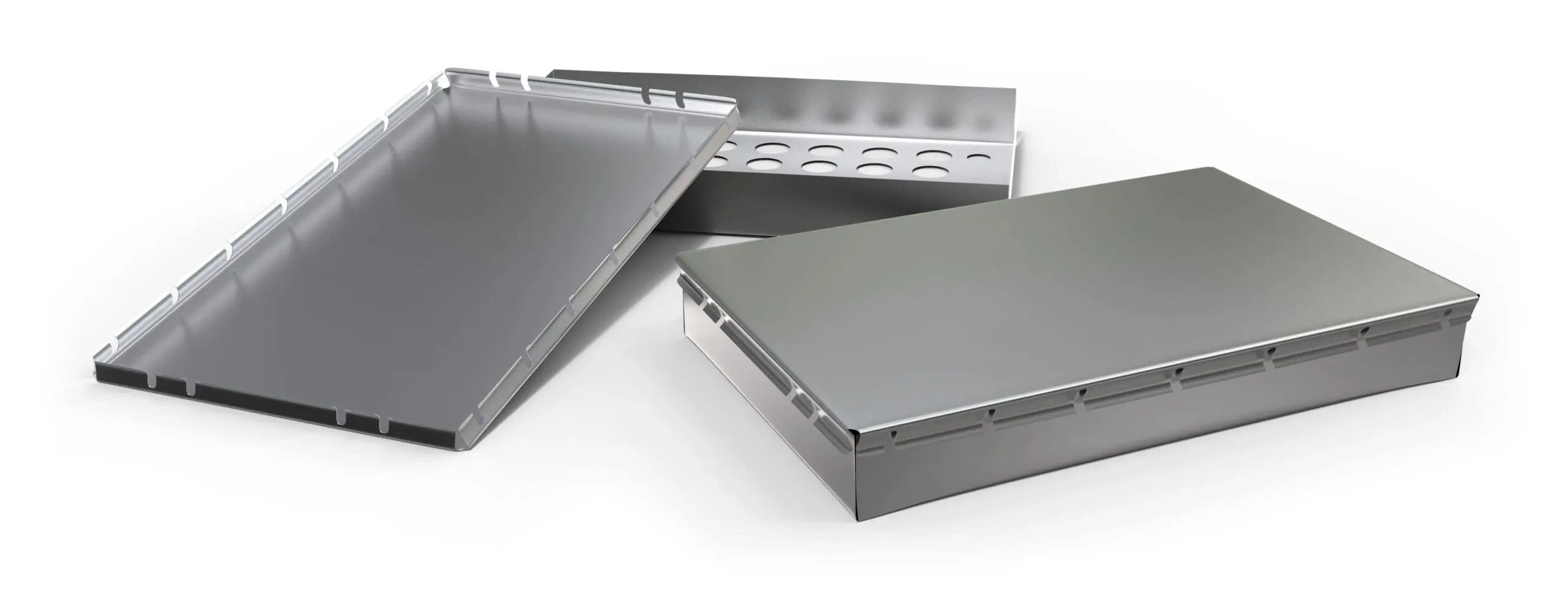

Among the various etching techniques available, photochemical etching (PCE) stands out for its ability to create complex geometries, microfeatures, and burr-free edges without introducing heat. This stress-free process preserves the alloy’s original properties, avoids heat-affected zones, and allows for simultaneous etching on both sides of the material, improving efficiency and reducing lead times. It’s particularly well-suited for manufacturing heatsinks/heat exchangers, EMI shielding components, and other detailed parts with intricate patterns.

Compared to methods like laser cutting and wire EDM, which may distort material properties due to localized heating, aluminum photochemical etching offers a cost-effective and precise solution for both prototyping and high-volume production. With no tooling costs, fast design iterations, and the ability to process thin profiles and custom shapes, photochemical etching provides unmatched flexibility for manufacturers.

At E-Fab, we specialize in etching aluminum alloys, including 1100, 5052, and 6061, using advanced chemical etching techniques to deliver clean, accurate, and reliable results. Our etching process ensures high-definition features, superior surface finish, and complete design freedom, ideal for industries that demand precision without compromise.

At E-Fab, we specialize in photochemical etching aluminum to deliver reliable, repeatable results. Aluminum chemical etching is a precise and cost-effective chemical process for creating complex, lightweight, and high-quality aluminum components used in industries such as aerospace, automotive, and electronics. This process is used to create detailed designs and burr-free components, making it a preferred method for achieving high precision and handling complex shapes. The chemical process selectively removes unprotected parts of the metal surface of the aluminum to achieve detailed designs and intricate features. The components produced through aluminum chemical etching are known for their high accuracy and superior surface finish.

Whether you’re working with 1100, 5052, or other alloys and tempers, E-Fab ensures clean, accurate results with every etched aluminum component through our precise manufacturing process.

E-Fab’s chemically etched aluminum parts are used in mission-critical industrial applications across a broad range of sectors, including aerospace, electronics, and medical devices for critical uses:

E-Fab produces photo-etched aluminum components for applications that demand high precision and complex part geometries. With E-Fab’s aluminum photo etching expertise, your components are engineered for performance from prototype to production.

E-Fab offers unmatched capability and flexibility when it comes to aluminum etching and forming aluminum to precise standards and specifications, utilizing advanced manufacturing processes:

Our proprietary process breaks through aluminum’s natural oxide layer to ensure crisp, consistent profiles across batches.

E-Fab is not just another metal etching shop. We’re a collaborative, California-based partner trusted by engineers in aerospace, medical, and high-tech industries for over 40 years.

We don’t just etch, we engineer success. When it comes to etched aluminum components, E-Fab delivers results that meet the highest standards in performance and precision.

We are known for our experience and expertise in:

Research & Development

Engineering

Design Support

Photochemical Etching

Forming

Bonding

High-Frequency Substrate

CNC Machining

Plating

Deburring

Micromachining

Prototyping

Supply Chain Acquisitions

Whether you need custom chemical etching of aluminum parts for a new prototype or scalable production, E-Fab is here to help.

Contact us today to see how E-Fab can bring your etched aluminum components to life with precision, speed, and quality.

E-Fab | Precision in Every Element – Specialists in nickel photochemical etching for the world’s most demanding applications.