Engineers and designers choose aluminum as their material of choice thanks to its versatile, strong, and lightweight properties. Plus, aluminum comes in a wide range of alloys that are useful in industrial, mechanical, and technical applications.

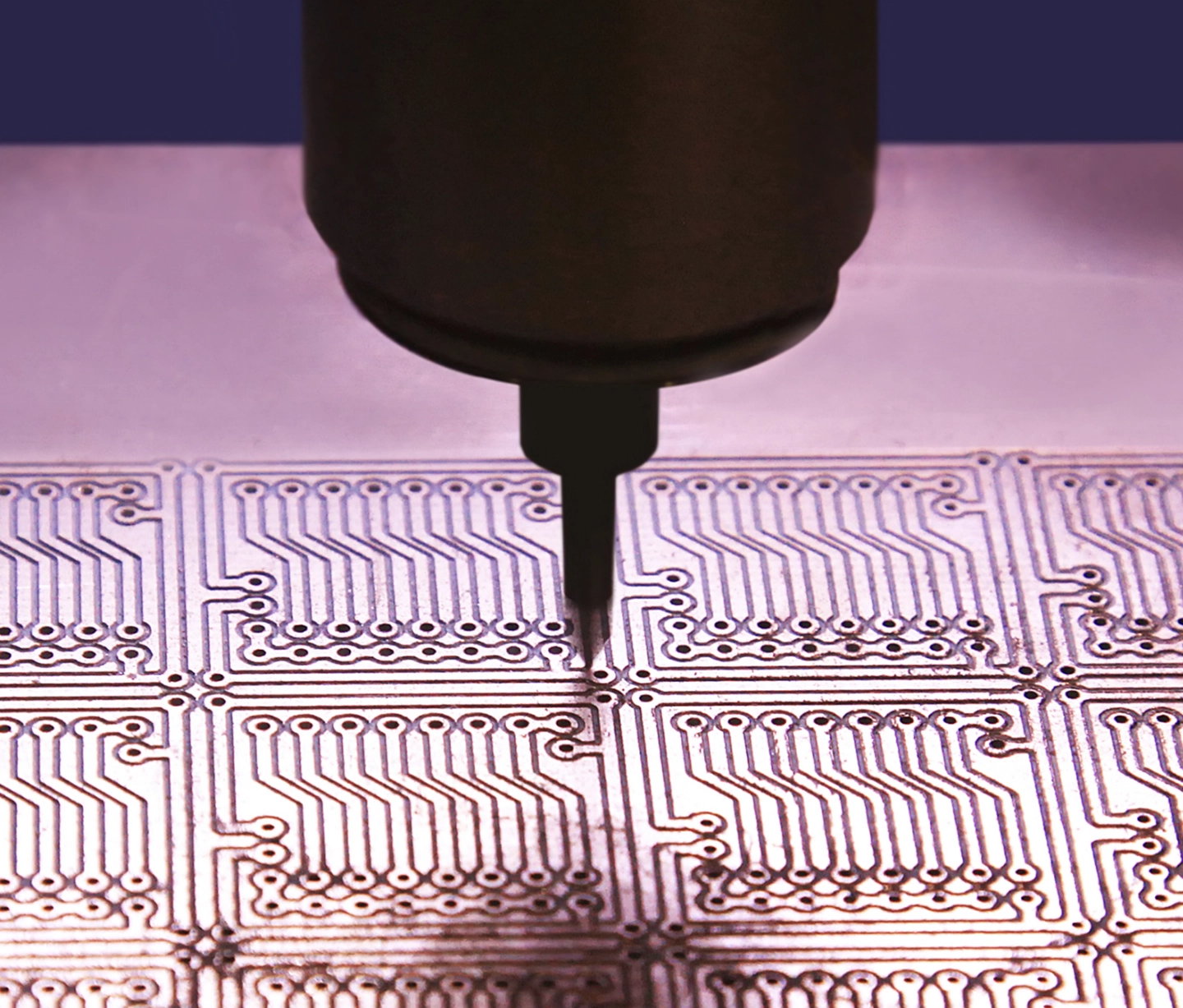

E-Fab’s experience manufacturing precision parts from aluminum includes RF shields, circuits, and flex circuit boards. We supply these parts to defense, technology, and industrial clients.

We welcome your questions about how to use aluminum for your parts.