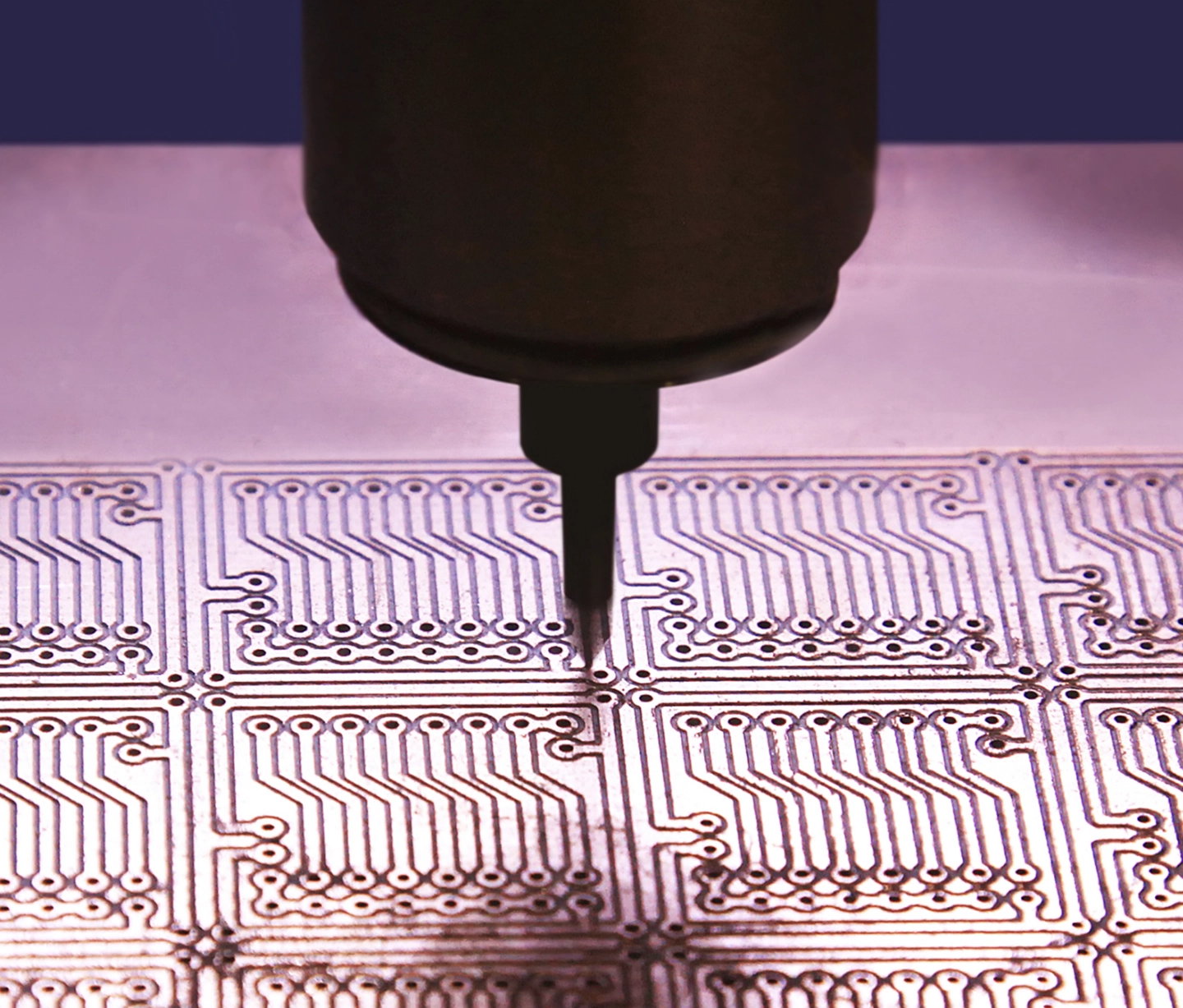

The advantages of using brass over many other metals are many and varied, making it a good choice for applications in electronics, automotive, and telecommunications industries.

E-Fab’s engineers and manufacturers leverage brass’s affordability, flexibility, and machinability for precision part manufacturing. Also, since brass does not conduct electricity as efficiently as other metals, it’s a good choice for use in shields or other parts where low-spark risks are required.

We welcome your questions about how to use brass for your parts.