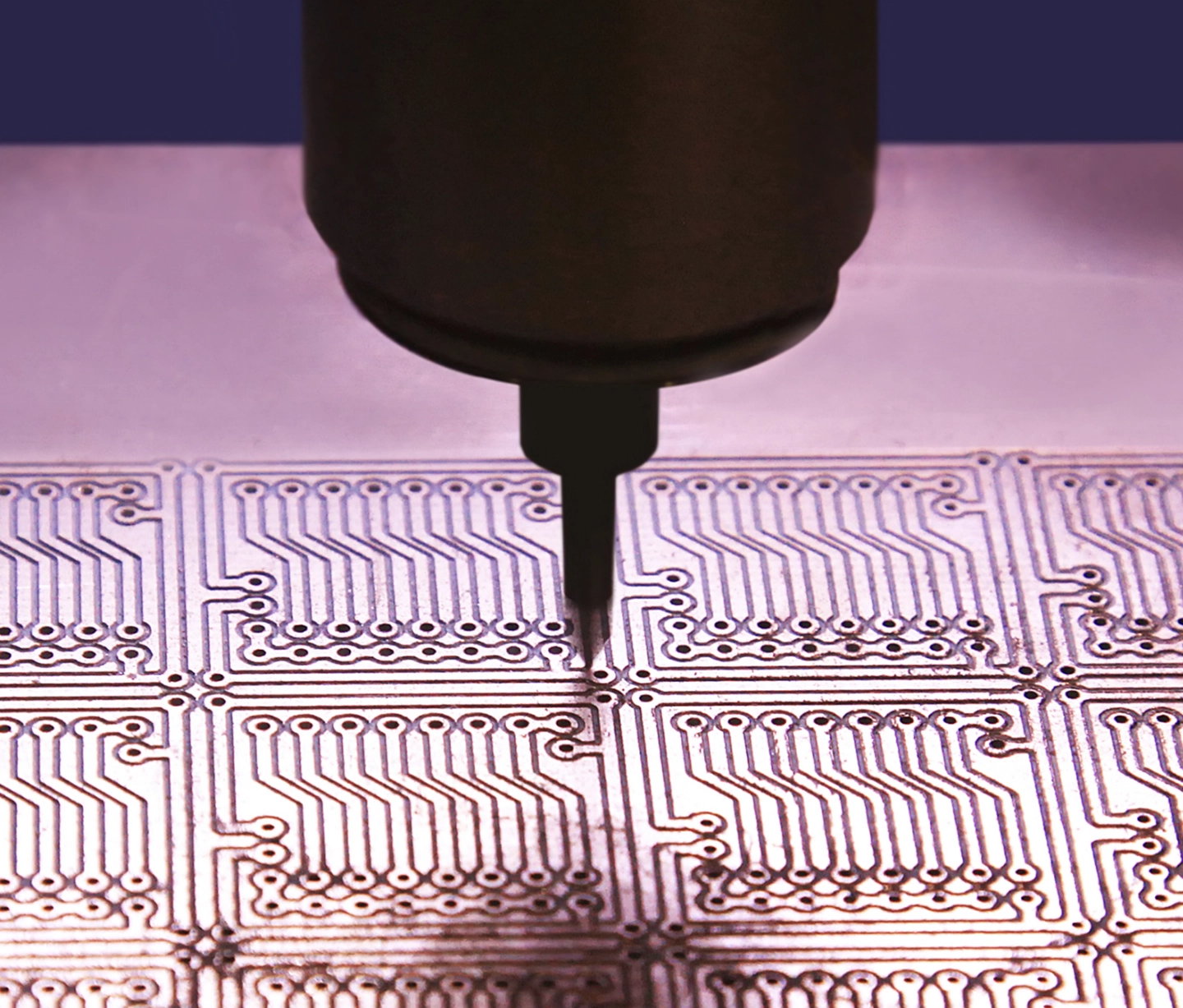

Picking a metal that can withstand several compromising environments is crucial for part dependability and longevity. Inconel is a material that offers impressive strength, elemental resistance, and flexibility.

E-Fab customers ask us to manufacture precision parts from Inconel for industrial, aerospace, electronics, and green energy applications.

We welcome your questions about how to use Inconel for your parts.