Precision metal fabrication, including sheet metal fabrication, plays a crucial role in the medical industry. From minimally invasive surgical tools to implantable components and diagnostic devices, the demand for reliable, high-precision parts is growing exponentially. Medical equipment often consists of dozens of unique parts, each requiring precise fabrication to ensure optimal performance and safety. But as medical technologies advance, so do the challenges involved in fabricating the metal parts that power them.

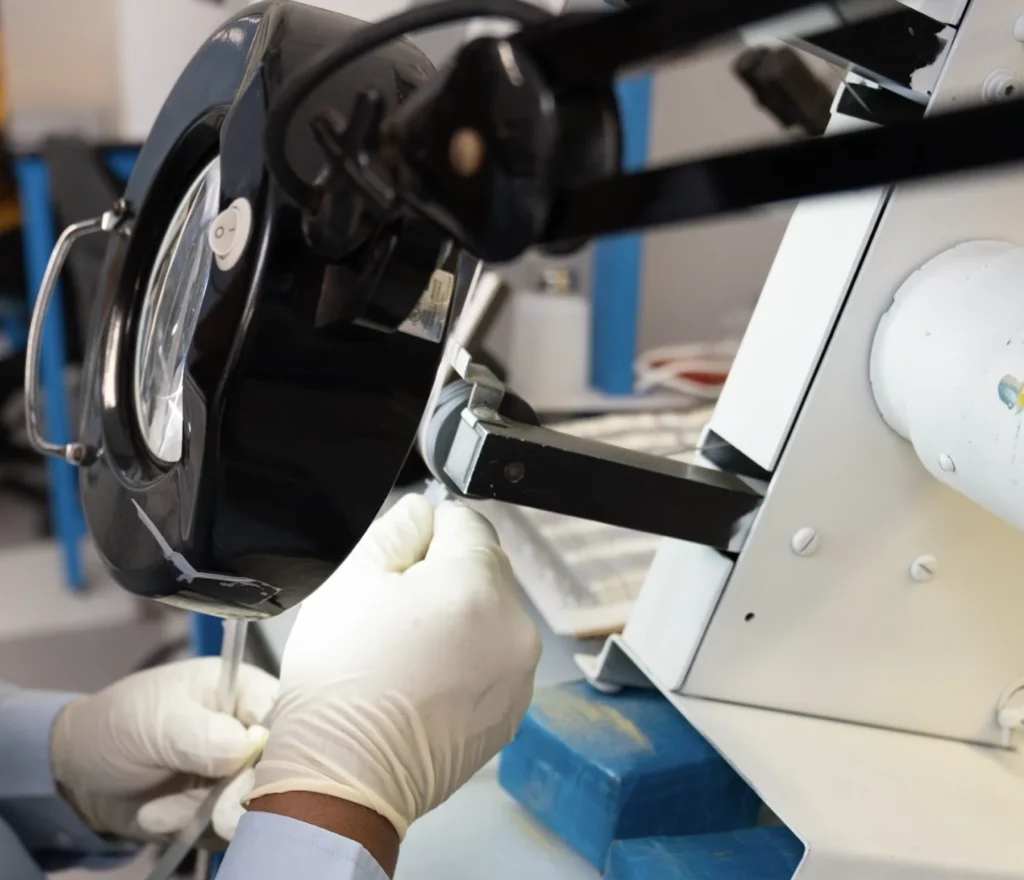

At E-Fab, we understand the increasing complexity, regulatory requirements, and performance expectations facing medical device manufacturers. We fabricate custom metal components using advanced photochemical etching capabilities engineered to meet these demands, offering precision, flexibility, and cleanliness that traditional fabrication methods struggle to match. In addition to photochemical etching, the medical device industry relies on a variety of fabrication methods and materials to produce components for a wide range of applications.

Our team works closely with customers in the medical industry to meet their specific sheet metal needs. In this article, we will explore the most common challenges in medical equipment fabrication and how E-Fab provides exceptional solutions to address them.

Challenge #1: Tight Tolerances and Complex Geometries

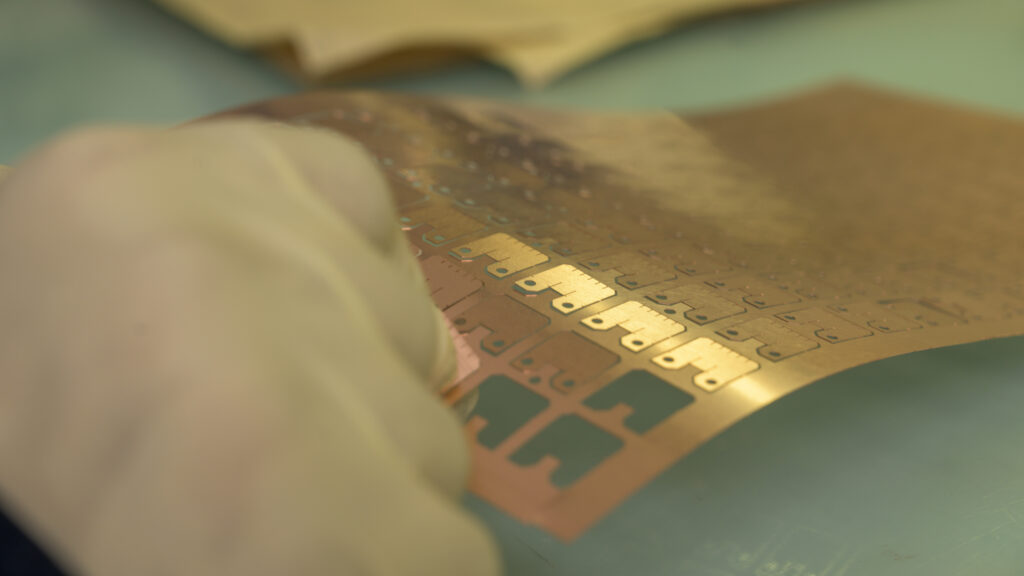

Medical components often require micron-level tolerances and intricate designs that leave no room for error. Complex assemblies often require precise integration of multiple components to ensure the functionality and reliability of a vast range of medical devices. Whether it’s a stent component, catheter part, or sensor housing, the margin for deviation is razor thin.

The problem: Traditional methods like laser cutting or stamping can create burrs, introduce heat-affected zones, or deform thin materials, compromising performance and reliability.

E-Fab’s Approach:

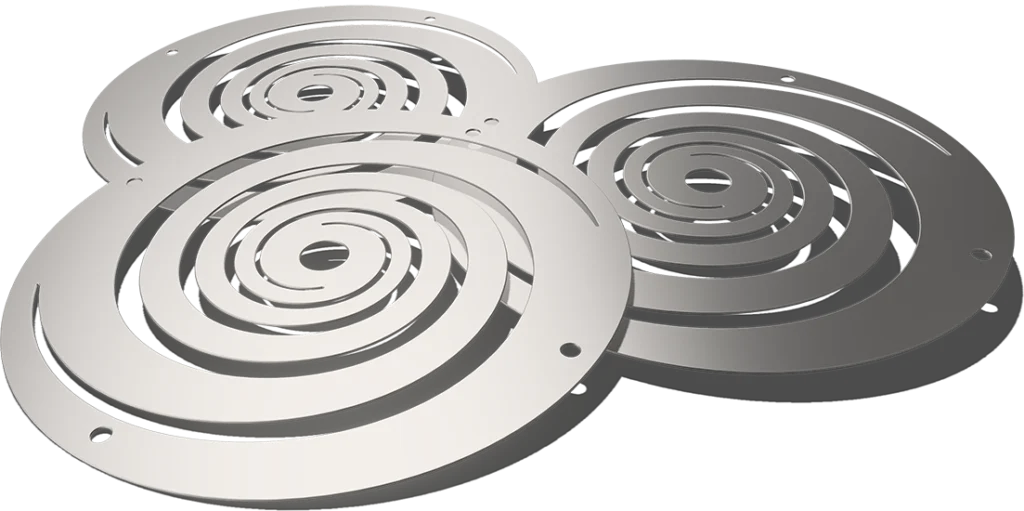

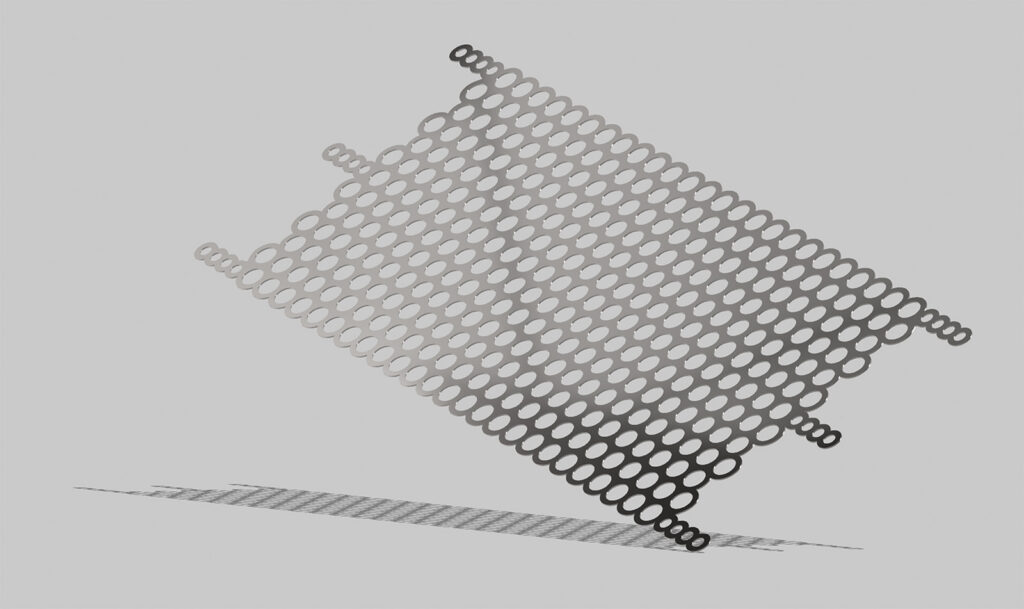

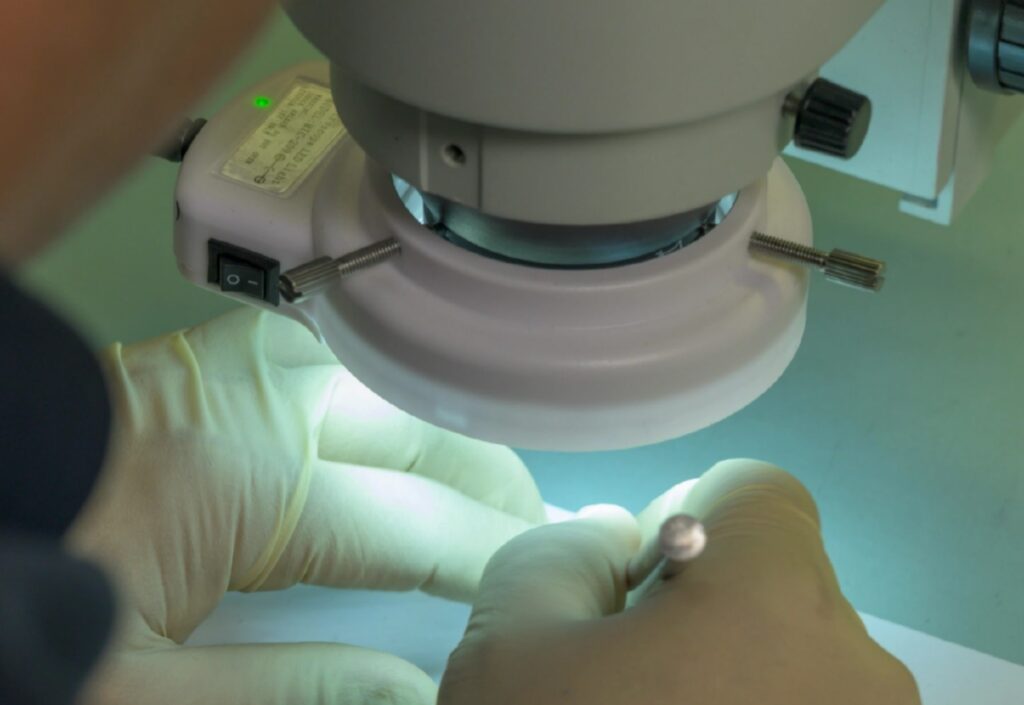

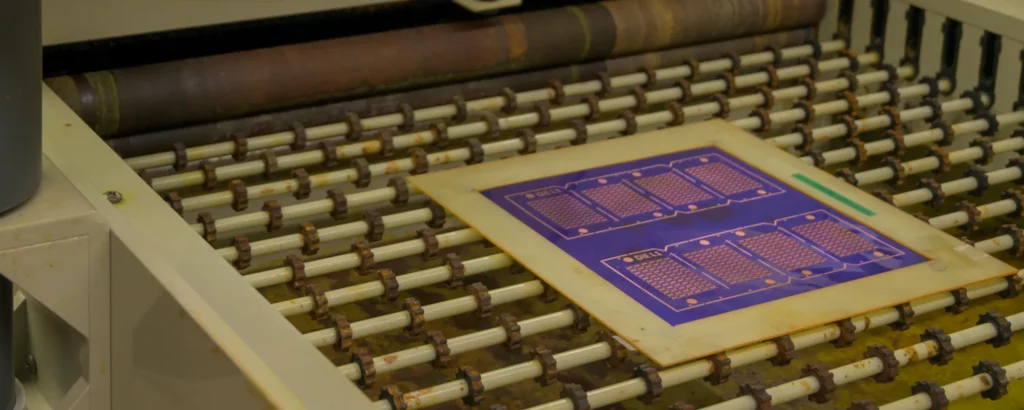

Our photochemical etching process uses a controlled chemical reaction to remove material without applying heat or mechanical force. This non-invasive technique achieves tight tolerances with high repeatability, producing parts that meet the exacting standards of modern medical devices. This process enables the manufacture of highly detailed parts for advanced medical device assemblies.

Challenge #2: Biocompatibility and Material Selection

Medical devices must be made from materials that are safe for human contact, resistant to corrosion, and compliant with biomedical standards.

The problem: Not all fabrication methods are suitable for delicate, biocompatible metals, including common sheet metal parts. Mechanical stress, contamination, or heat can alter the material’s properties.

E-Fab’s Resolution:

We specialize in etching biocompatible metals such as titanium, stainless steel, and nickel alloys, materials commonly used in implantable devices and surgical tools, showcasing our proven track record.Because photochemical etching introduces no mechanical stress or heat, the material retains its original structural and chemical integrity, ensuring both safety and long-term performance.

Challenge #3: Cleanliness and Burr-Free Finishes

For surgical instruments, implantable components, and diagnostic devices, surface cleanliness is paramount. Burrs and micro-contaminants can pose serious risks in sterile environments.

The problem: Mechanical processes often leave sharp edges or micro-debris that require secondary cleaning and finishing.

E-Fab’s Answer:

Photochemical etching delivers clean, burr-free components right off the production line, enhancing efficiency. With smooth edges and consistent finishes, our parts help reduce contamination risk and eliminate the need for additional processing, saving time and preserving quality. Similar standards of cleanliness are required in food and pharmaceutical equipment fabrication, where strict quality requirements ensure safety and compliance.

Challenge #4: Scalability from Prototype to Production

Medical device innovation moves fast. Companies must prototype quickly, iterate confidently, and scale without sacrificing precision.

The problem: Some manufacturing processes require costly tooling or introduce inconsistencies when moving from prototyping to production.

E-Fab’s Methodology:

We offer rapid prototyping with production-level precision, using the same etching techniques and equipment throughout the product lifecycle. This ensures consistent quality, reduces transition risks, and supports agile development timelines. Our processes also enable efficient integration of components at the final assembly line, streamlining the move to full-scale production.

Challenge #5: Traceability and Quality Assurance

Manufacturing medical devices requires unwavering adherence to strict regulatory standards to ensure product safety, performance, and marketability. Guidelines from agencies like the FDA and standards such as ISO 13485 and 21 CFR Part 820 govern every aspect of production, from material sourcing and design to labeling and post-market surveillance.

The challenge: Without robust traceability and documentation, manufacturers risk compliance issues that can delay approval, compromise patient safety, or result in costly recalls.

Here’s our Solution:

E-Fab maintains rigorous process documentation, lot-level traceability, and quality assurance protocols across all projects. Our team is deeply experienced in medical manufacturing requirements, and our operations are ISO 9001 certified, RoHS compliant, and ITAR registered. These practices ensure full regulatory alignment and instill confidence that every part we deliver meets the highest quality and compliance standards.

By prioritizing transparency and regulatory rigor, E-Fab helps medical device manufacturers navigate an array of complex requirements while delivering components that support patient safety and long-term device reliability.

Why Choose E-Fab for Medical Component Fabrication?

With decades of experience delivering high-precision metal parts to the medical industry, E-Fab is a trusted partner for engineers and sourcing professionals seeking:

- Proven expertise in critical medical applications

- Engineering support to optimize part designs for manufacturability

- Micro-scale accuracy and consistent performance across batches

- Deep understanding of biocompatibility, sterility, and compliance

- A partner you can rely on for consistent quality and regulatory compliance

At E-Fab, we’ve fabricated everything from catheter components and implantable housings to diagnostic sensors and surgical tool parts, all with the precision and care that medical applications demand. Our team of experts offers comprehensive fabrication and manufacturing services for medical device projects, supporting every stage from concept to production. As an experienced manufacturer, we’ve found that most of these devices require a wide range of custom metal components, and E-Fab is equipped to deliver everything from brackets, adapters, welded frames, and more. Our cost-efficient fabrication solutions help keep your project on budget without sacrificing quality. We help bring your medical device concepts to life through expert sheet metal fabrication and technical support. We have put together a team with decades of combined experience to complete even the most complex fabrication and welding projects for the medical industry.

Get Started with E-Fab Today

Metal fabrication and advanced manufacturing techniques remain fundamental to the production of high-quality, safe, and effective medical devices. As the medical device industry continues to evolve, E-Fab continues to stay ahead of the curve by embracing new technologies, adapting to changing regulatory requirements, and responding to the needs of patients and healthcare providers.

The future of medical device manufacturing will be shaped by ongoing innovation, a commitment to quality and safety, and the ability to deliver reliable solutions in a competitive market. By prioritizing excellence in fabrication, compliance, services, and product development, companies that work with E-Fab can continue to make a meaningful impact on patient care and the broader healthcare industry.

If you’re facing metal fabrication challenges in your medical device manufacturing development, E-Fab is here to help. Our photochemical etching process offers the accuracy, cleanliness, and flexibility your project needs, from concept to prototype, all the way to full-scale production.

Contact our team or Request a Quote to discuss your custom medical component needs.