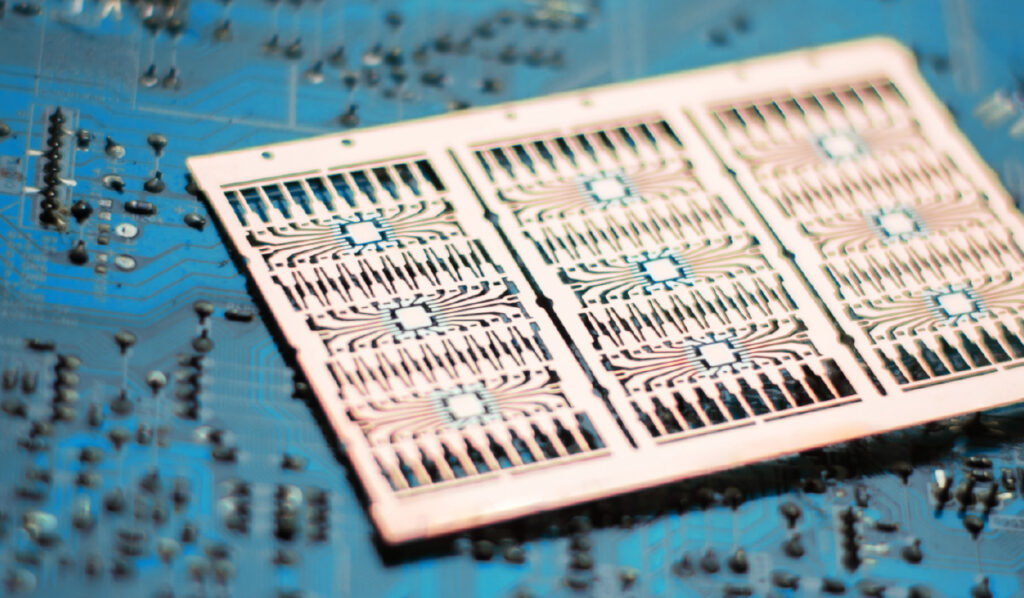

Semiconductor Etching for Precision Components

E-Fab, Delivering accuracy, repeatability, and innovation in semiconductor manufacturing, without compromise.

Powering Modern Semiconductor Manufacturing Technology

From smartphones and medical devices to automobiles and next-generation communication systems, semiconductors drive today’s innovations. At the core of these devices are precision components that must meet exacting standards to keep pace with smaller, faster, and more efficient chips.

As advanced devices increased in complexity and miniaturization, the demand for more sophisticated etching methods has grown. These intricate architectures require cutting-edge etching technologies to achieve the necessary accuracy and control.

For engineers, sourcing managers, and procurement teams, the challenge is finding a partner who can deliver components that support miniaturization, precision, and high-volume production—without sacrificing speed or cost-effectiveness.

That’s where E-Fab comes in. With decades of expertise in photochemical etching, we manufacture burr-free, stress-free, and highly repeatable components tailored to semiconductor applications.

What is Semiconductor Etching? Let's Break It Down Quickly

Etching refers to the process of removing material from a wafer or metal surface with extreme precision to create patterns, circuits, or structural features. Its primary role in manufacturing is to enable microscale features essential for modern chips, devices, and supporting components.

There are two basic mechanisms involved in etching: physical and chemical.

- Physical etching – ion bombardment, sputtering

- Chemical etching – chemical reactions with etchants

- Most processes combine both

These basic mechanisms underpin all semiconductor etching processes, allowing for precise pattern transfer and the fabrication of high-aspect-ratio microstructures

Etching Methods: Wet Etching and More

Wet Etching

- Uses chemical solutions (also known as wet chemical methods)

- Characterized by its isotropic nature, meaning wet etch removes material uniformly in all directions

- Simple, good for large wafer areas

- Risk of undercutting → reduced pattern fidelity

- Wet etch processes are often used in the initial etching steps for cleaning or large-area patterning

Dry etching (Plasma, RIE)

- Anisotropic (directional) → high precision

- Controlled by gas composition, chamber pressure, power density

- Enables deep trenches, narrow vias (VLSI/ULSI)

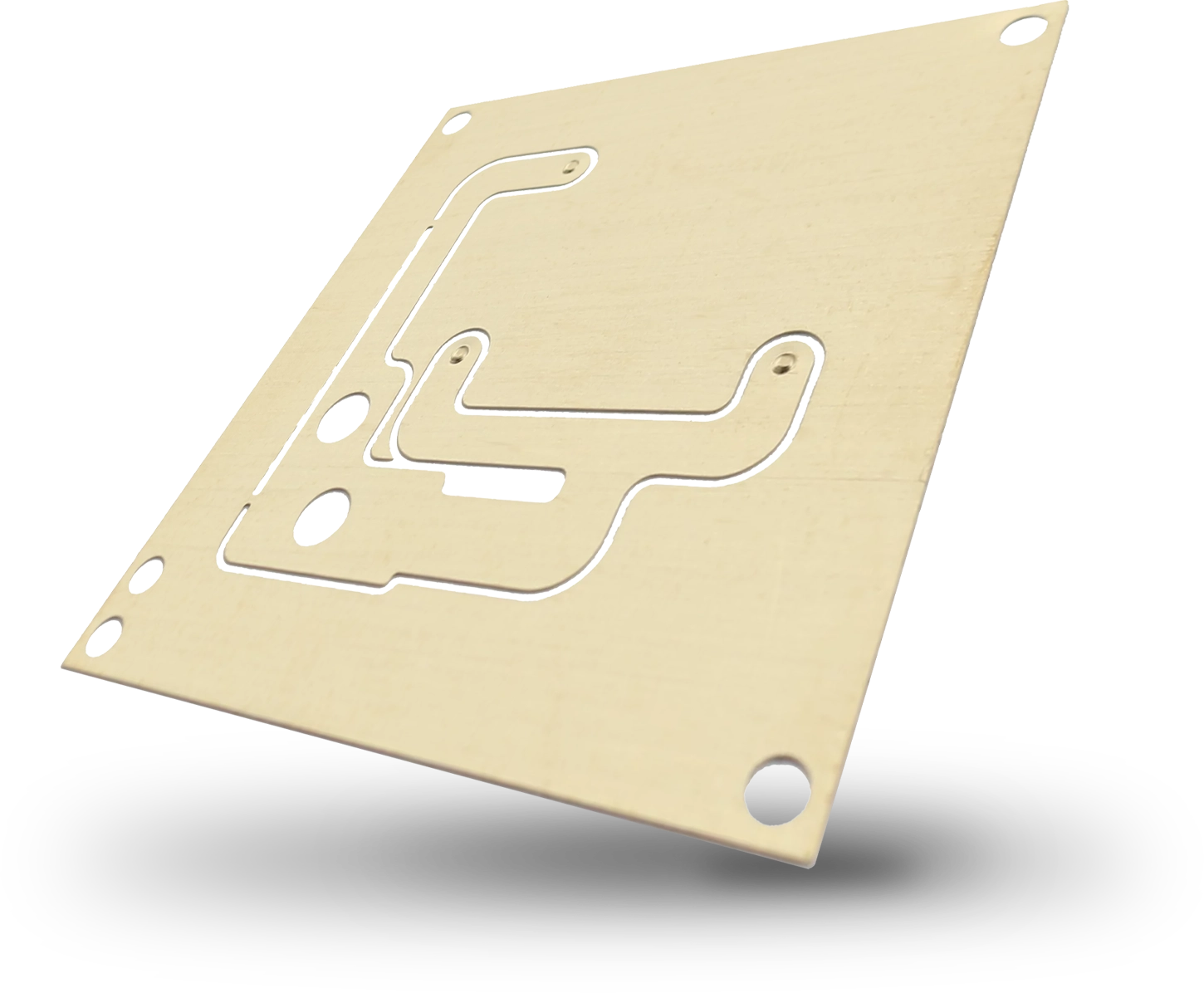

Photochemical etching/machining (E-Fab specialty)

- Uses photoresist + chemical solutions on metals

- Produces sharp, burr-free, stress-free thin metal components

- Superior to laser cutting (avoids heat damage/slag) and stamping (avoids burrs, geometry limits)

- Best suited for semiconductor precision metal parts

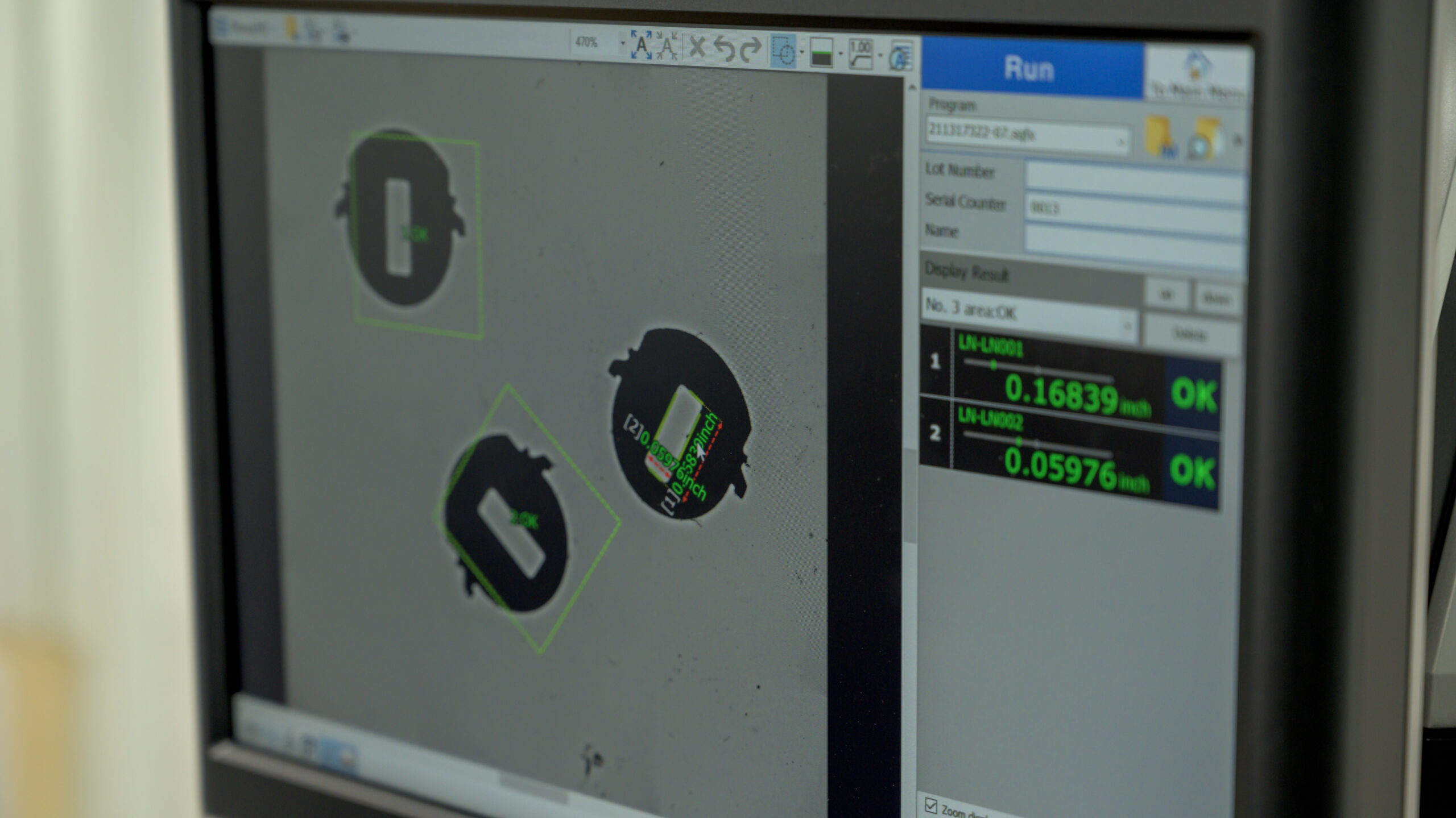

Key Process Parameters - Photochemical Etching

Etch Rate:

- Determines throughput & dimensional accuracy

- Controlled by material type, etchant chemistry (e.g., ferric chloride), temperature, concentration & agitation

Etch Depth & Undercut

- Full-thickness etching of thin metals

- PCE is an isotropic process, which means it etches laterally as well as vertically → lateral undercut must be controlled (etch time, resist adhesion and quality, solution stability)

Photoresist & Mask Quality

- Accurate UV imaging and strong resist adhesion and conformity along features for multi-step etching are critical for fine features & tight tolerances

Material Properties

- Alloy composition, grain structure, hardness and material thickness influence etch rate and feature tolerances

Etchant Management

- To maintain product quality, etching chemistry must be maintained. Such factors include: concentration control, temperature and pH regulation, filtration to remove reaction by-products, and continuous replenishment.

Summary

- Etching plays a critical role across various stages of semiconductor manufacturing, enabling the creation of high-precision micro- and nanostructures.

- Etching is essential for forming structures and removing materials to create precise device features and complex geometries.

- Success in semiconductor etching depends on precise control of etch rate, depth, aspect ratio, and chemistry.

- Wet etching = simple, large-area processing; dry etching = precision, anisotropic features.

- Photochemical etching = ideal for burr-free, stress-free semiconductor metal components.

Benefits of Photochemical Etching for Semiconductor Components

Choosing the right etching method can directly impact semiconductor performance and reliability. With E-Fab, customers gain:

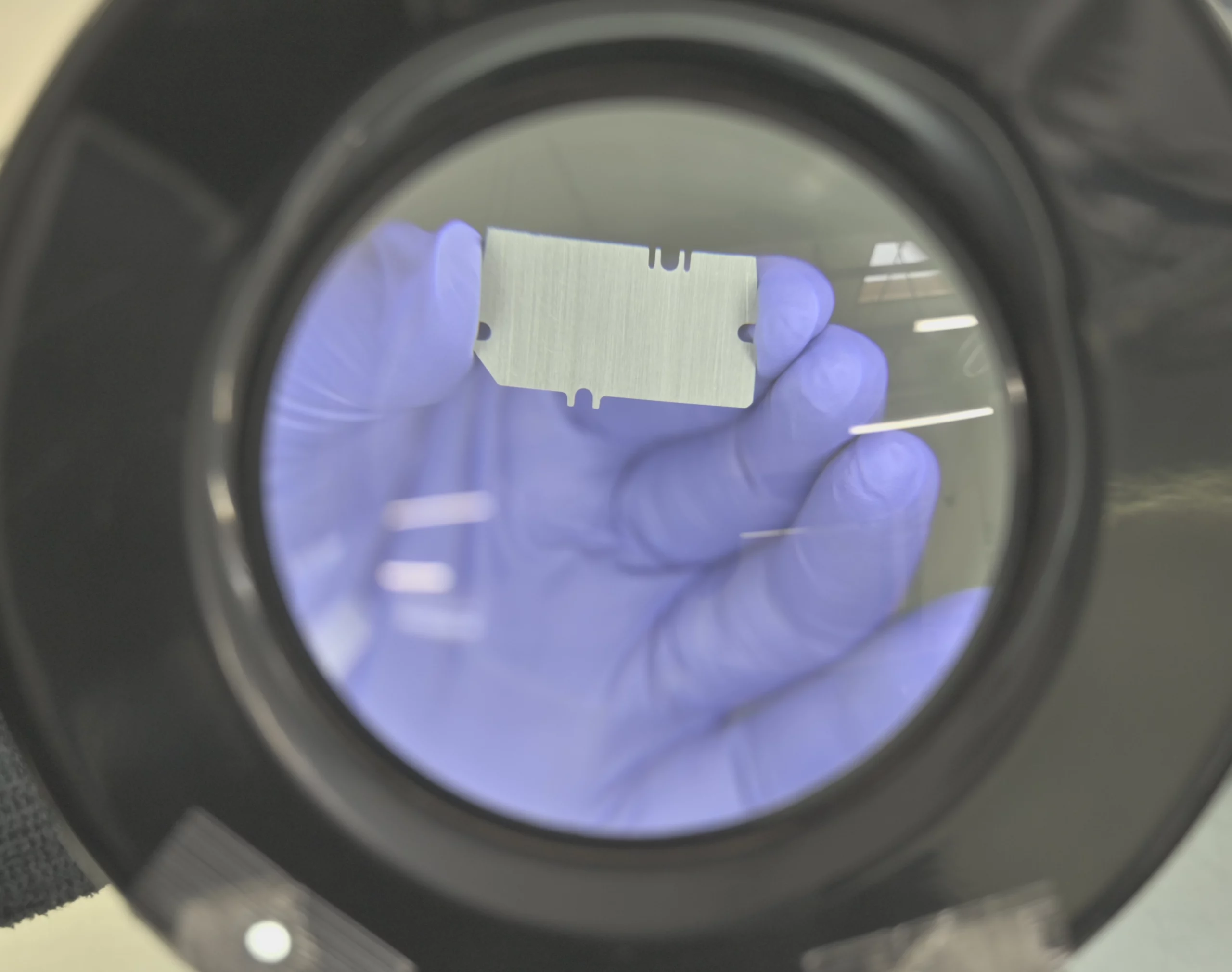

- High precision and repeatability: Tight tolerances for even the most intricate designs.

- Complex geometries: Capability to produce patterns that are impossible with mechanical methods.

- Stress-free, burr-free components: No warping, micro-cracks, or tool-induced damage.

- Cost-effectiveness: Affordable prototyping and efficient scaling for volume production.

- Material versatility: Expertise across stainless steel, copper, nickel, titanium, and more, including thin film and new materials relevant to advanced semiconductor applications.

Components E-Fab Manufactures for Semiconductors

Our expertise spans across semiconductor metal fabrication for critical applications. E-Fab delivers:

- Lead frames for microelectronics, including use in wire bonding applications

- Contact springs for secure electrical connections, also suitable for wire bonding processes

- Heat sinks to manage thermal performance

- EMI/RF shields for EMI/RFI protection

- Fine meshes and filters for particle management

- Custom micro-structures tailored to emerging technologies, enabling fabrication of intricate microscale components

E-Fab’s components are engineered to meet the stringent requirements of VLSI and ULSI designs, as these advanced architectures and ULSI designs demand highly precise, anisotropic etching processes for complex device fabrication.

E-Fab Capabilities & Expertise

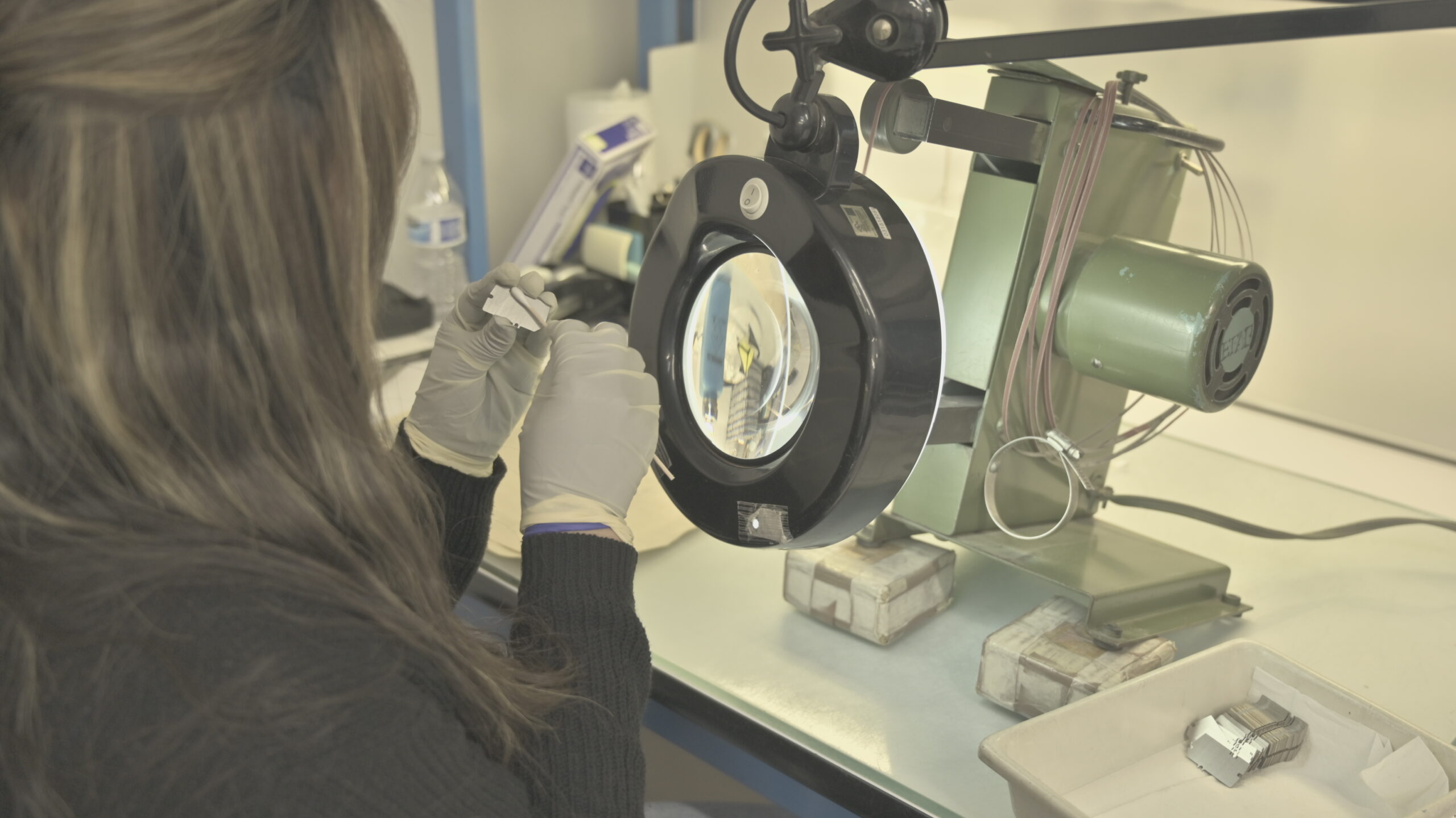

Our customers choose us not just for what we make, but how we work:

- Miniaturization expertise: Mastering tolerances down to microns.

- Material handling knowledge: Including expertise in handling silicon-based materials for semiconductor applications, as well as biocompatibility for specialized applications.

- Rapid prototyping & scalability: Accelerating time-to-market.

- Certified quality: ISO-certified processes ensure repeatable results.

- Collaborative process: From design input to delivery, our engineers work as an extension of your team.

Applications in Semiconductor Manufacturing

E-Fab’s etched components support a wide range of semiconductor and microelectronics applications:

- Microchips and integrated circuits

- Power electronics

- Sensors and MEMS devices

- Consumer electronics

- Telecommunications infrastructure

E-Fab’s etched components are used to create precise patterns and features on the wafer’s surface in a variety of semiconductor devices.

Whether it’s improving device performance, enabling miniaturization, or ensuring reliable connections, E-Fab’s etched solutions drive semiconductor innovation forward.

Why Partner with E-Fab?

With E-Fab, you don’t just get components, you gain a trusted semiconductor manufacturing partner:

- Decades of experience in semiconductor precision components

- In-house engineering support for design optimization

- Proven results across etched lead frames, shields, and fine microstructures

- Flexible volumes and fast lead times to keep production moving

Ready to Get Started?

Your semiconductor designs deserve a partner who understands both the science of precision and the urgency of production.