What to know from the experts at E-Fab

In industries where precision and performance are non-negotiable, such as aerospace, medical, defense, and electronics, engineers face a common challenge: how to produce intricate, high-performance components from advanced metals without compromising quality or efficiency.

Traditional methods like stamping, machining, or laser cutting often fall short, especially when working with ultra-thin materials that require delicate detail, stress-free edges, or tight repeatability. That’s where thin metal etching, and more specifically, chemical etching of thin metals, becomes a game-changing solution.

At E-Fab, we specialize in precision thin metal etching, enabling engineers and sourcing managers to push the limits of design while ensuring reliable, cost-effective manufacturing.

What is Thin Metal Etching?

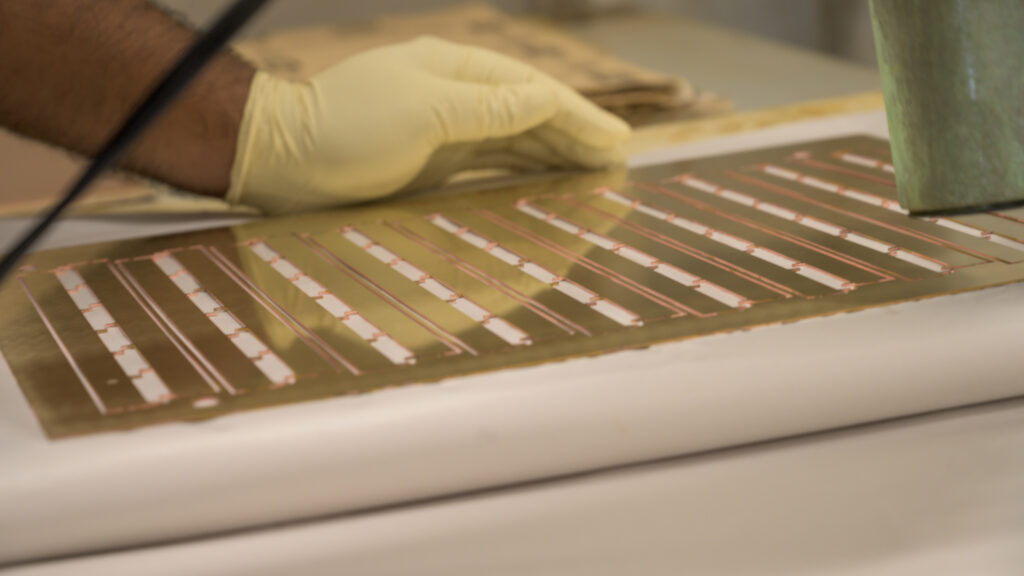

Thin metal etching (also known as photo etching thin metals or chemical etching thin metals) is a subtractive manufacturing process that uses photolithography and chemical etchants to selectively remove areas of a sheet metal. In the first step of the photochemical etching process, a photoresist is applied to the sheet metal, and UV light is used to define unprotected areas, resulting in the imaged design. Chemistry such as Ferric chloride is then used as the chemical etchant to selectively dissolve the unprotected areas of the metal, allowing for precise control over dimensions, thickness, and material thickness. This processing method avoids mechanical forces and heat-affected zones, preserving the properties of the metal sheets. The photochemical machining process enables the manufacture of burr-free, highly precise, and repeatable components with tight control over dimensions and thickness for mission-critical applications. Compared to other manufacturing processes and traditional manufacturing methods, photochemical etching offers advantages such as minimal lead time, suitability for a variety of sheet metals, and the ability to achieve complex designs without deformation. Value-added services like plating, forming and post-processing can further enhance the final product.

The Thin Metal Etching Process

- Photoresist Lamination – A light-sensitive photoresist is applied to the metal sheet.

- UV Exposure – A phototool (mask) with the component design is aligned and exposed to UV light.

- Chemical Etching – Exposed areas are etched away using a controlled chemical solution.

- Final Component – The resist is removed, leaving behind the finished part with clean, distortion-free edges.

Benefits of Thin Metal Etching

- Burr-Free Results – Eliminates the need for costly secondary finishing.Burr-free edges also enable precise alignment of layers for further assembly or bonding.

- No Heat Distortion – Material integrity remains intact since the process doesn’t introduce thermal stress.

- High Repeatability – Ideal for both prototyping and high-volume production.

E-Fab has honed this process to deliver precision thin metal etching results that consistently meet the exacting standards of aerospace, defense, and medical industries.

Techniques in Thin Metal Etching

E-Fab’s photochemical etching services deliver precise, thin metal parts for industries such as electronics, medical systems, and industrial machinery.

- Rapid Prototyping with Photo Etching Thin Metals. Engineers can quickly iterate designs without costly retooling.

- Volume Production with Chemical Etching Thin Metals. Once designs are locked in, the process scales easily to high-volume runs while maintaining tight tolerances.

This flexibility makes photo etching thin metals the preferred solution when both speed and precision are critical, offering a range of processing options to meet different project requirements.

Materials Commonly Used in Precision Thin Metal Etching

One of E-Fab’s differentiators is our ability to etch challenging and specialty metals that others often avoid:

- Titanium – Lightweight, strong, and biocompatible. Common in medical implants and aerospace applications.

- Molybdenum – High strength and thermal resistance, making it ideal for electronics and aerospace shielding.

- Tungsten – Offers increased corrosion resistance, making it highly durable in harsh environments.

Beyond these, E-Fab also etches metals such as copper alloys, nickel alloys, and stainless steel, broadening the design possibilities for precision thin metal etching projects. E-Fab has expertise in etching a wide range of sheet metals for various industrial applications, including electrical, medical, and electronic components.

Key Takeaways

Low-Cost Tooling Options in Thin Metal Etching

- Digital tooling eliminates the need for expensive hard tooling used in stamping or die-cutting.

- Uses photoresist and chemical etchants to define parts, reducing upfront costs and lead times.

- Ideal for prototyping and low-volume production where design changes are frequent and reliability is essential.

- Enables fast, affordable iteration, critical in aerospace, automotive, and industrial applications.

Prototyping and Production Capabilities

- Supports both rapid prototyping and full-scale production with the same process.

- Accelerates design validation and testing by quickly producing prototypes.

- Seamlessly scales from a handful of parts to thousands, maintaining tight tolerances.

- Reduces lead times and production costs while ensuring consistent quality.

- Flexible solution for industries needing both small-batch and high-volume production.

Quality and Precision Control in Thin Metal Etching

- Precision managed at every stage: material selection, photoresist application, and etchant control.

- Strict quality control with inspections and testing ensures specification compliance.

- Achieves tolerances as tight as ±0.001 inches.

- Delivers high-quality, reliable parts for aerospace, defense, medical, and electronics.

- Consistently meets the most demanding precision requirements across industries.

Applications of Thin Metal Etching

Thin metal etching unlocks opportunities across industries where complexity, precision, and scalability are essential. E-Fab is committed to understanding customer needs and project details to deliver tailored solutions that meet specific requirements.

- Aerospace & Defense

- Lightweight shielding, precision filters, and micro-components where exact dimensions are critical for performance and safety.

- Medical

- Surgical tools and implantable devices using biocompatible metals like titanium and stainless steel, manufactured to precise dimensions for patient safety and regulatory compliance.

- Electronics & Telecom

- EMI/RFI shields, fine-pitch connectors, and etched circuit components that require tight control of dimensions for optimal functionality.

- Industrial & Energy

- Custom thin metal parts for sensors, renewable energy, and instrumentation, all produced with attention to detailed specifications and accurate dimensions.

- Custom thin metal parts for sensors, renewable energy, and instrumentation, all produced with attention to detailed specifications and accurate dimensions.

By relying on photo etching thin metals, these industries achieve designs impossible to replicate with machining or stamping. E-Fab proudly serves customers around the world, providing high-quality thin metal etching solutions tailored to diverse industry needs.

Why Choose Chemical Etching Thin Metals?

When evaluating processes, engineers and procurement teams consistently find that chemical etching thin metals delivers the best balance of precision, scalability, and cost efficiency.

- Enables Complex Designs – Intricate features and tight tolerances are achievable without compromise.

- Stress-Free Manufacturing – No mechanical force or heat is applied, preserving the integrity of delicate materials.

- Scalable & Cost-Effective – From rapid prototyping to full production, costs remain predictable and competitive.

At E-Fab, we’ve built decades of expertise around precision thin metal etching, not only mastering the process, but tailoring it to the toughest materials and most demanding applications. We are dedicated to customer satisfaction and building long-term partnerships by providing solutions that meet each customer’s unique requirements.

E-Fab: Quality and Precision at Every Stage

Thin metal etching isn’t just another manufacturing option; it’s an enabling technology that empowers engineers to create what other methods can’t. With rigorous process control and proven expertise, E-Fab consistently delivers high-quality, high-precision components.

In chemical etching thin metals, precision starts with material selection and continues through tightly controlled etchant chemistry, temperature, and exposure. Strict quality checks and testing ensure every part meets specifications, achieving tolerances as tight as ±0.001 inches. This level of accuracy makes precision thin metal etching ideal for industries where reliability is critical.

Whether it’s chemical etching thin metals for aerospace shielding, photo etching thin metals for medical devices, or precision thin metal etching for advanced electronics, E-Fab ensures unmatched results.

Ready to transform your designs into high-performance thin metal components? Contact E-Fab today to collaborate with our experts and explore the possibilities of precision thin metal etching.