Turning ideas and designs into innovative, technically accurate, and reliable parts for use across a multitude of industries takes expertise in materials and processes. The E-Fab core of engineers and manufacturers have decades of experience working with materials that can withstand the highest tolerances and offer the greatest efficiency.

We stand ready to understand your needs, talk to you about materials options, and process your parts.

Our relationships across The Partner Companies network enable us to procure materials we don’t have in stock.

To learn more about a specific material, click one of the material cards below.

Don’t see what you are looking for? Give us a call, and our engineering team will help.

Busbars

Apertures

Stiffeners

Encoders

Leadframes

Shields

Straps

Electrodes

Spacers

Retainers

Apertures

Encoders

Flexures

Mesh Screens

Clamps

Microstrip Contacts

Springs

Contacts

Microwave Circuits

Carriers

Apertures

Spacers

Labels

Ion Grids

Heatsinks

Gaskets

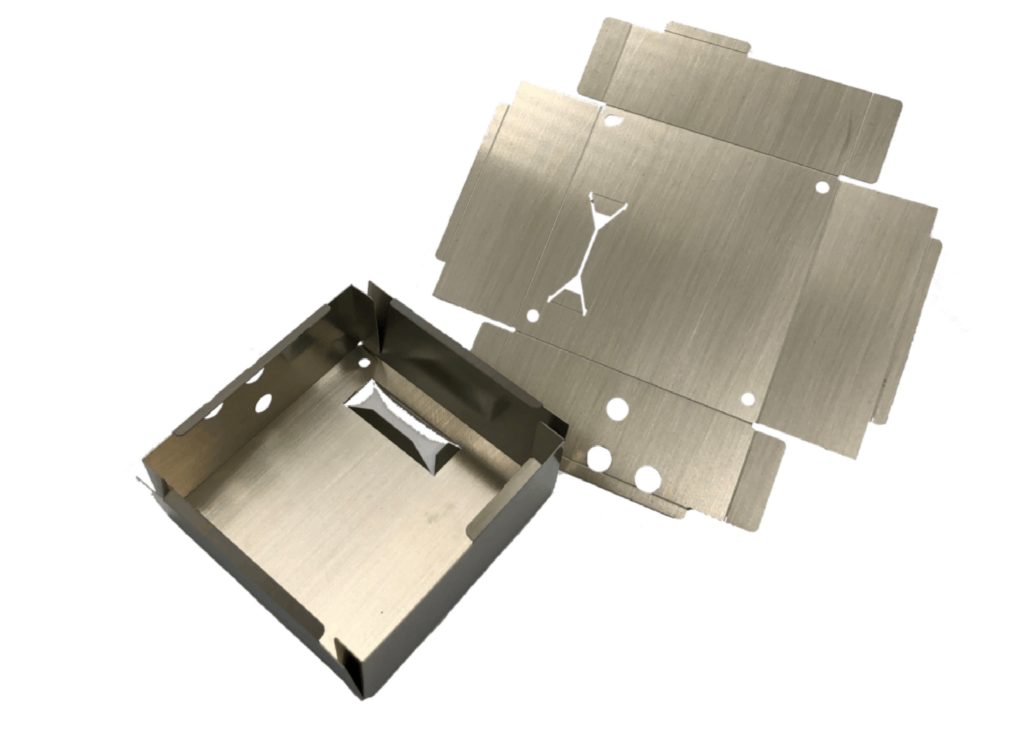

Shields

Spacers

Carriers

Microwave Circuits

Valves

About Our Aluminum Photochemical Etching Capabilities

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

1009 Timothy Drive

San Jose, CA 95133

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us