Explore the impact interference can have on medical device performance and the critical role RFI/EMI shielding continues to play in protecting sensitive electronics in medical equipment.

One of the main threats to the functionality and reliability of the medical equipment relied on by doctors and nurses is interference from unwanted electromagnetic signals. Precision-engineered RFI/EMI shields play a crucial role in the design and manufacture of modern medical devices and equipment.

As experts in RFI (Radio Frequency Interference) and EMI (Electromagnetic Interference) shielding, E-Fab provides proven, customized shielding solutions that meet the unique requirements of medical device manufacturers, ensuring optimal performance and regulatory compliance.

In this article, we explore the impact interference can have on medical device performance, the challenges faced in equipment design, and the critical role RFI/EMI shielding continues to play in protecting the sensitive electronics in medical equipment.

Medical Device Shielding: Understanding RFI/EMI Shielding

The best healthcare calls for the use of sensitive medical devices and equipment for accurate diagnoses and life-saving treatments. Any interference or malfunction in these devices can compromise the effectiveness of medical procedures and jeopardize patient safety, making electromagnetic interference (EMI) and radio frequency interference (RFI) a significant concern.

EMI shielding materials play a crucial role in protecting electronic devices, especially in medical device applications where reliable signal transmission is essential. EMI refers to any frequency of electrical noise, while RFI is a specific subset of electrical noise within the EMI spectrum. When exposed to EMI or RFI, unshielded devices are susceptible to disturbances like electric shocks, power surges, circuit failure, and distorted signals that can interrupt, obstruct, degrade, or limit the performance of a device.

Certain medical devices are particularly vulnerable to EMI and RFI, such as pacemakers, implanted devices, life-sustaining equipment, monitoring devices, and those with lead wires like defibrillators.

These devices are at a higher risk of interference due to their sensitivity and reliance on accurate signals for proper function.

Incorporating robust EMI shielding materials into medical devices helps mitigate these risks, ensuring reliable and interference-free operation in critical healthcare settings.

EMI can lead to false signals in medical equipment, potentially causing misinterpretation of data or incorrect device operation. For instance, a pacemaker may mistake EMI for irregular heart rhythms, posing a significant risk to the patient’s health.

Challenges in Medical Equipment Design

As the reliance on electronic technology rises and the need for RFI/EMI shielding grows, medical device manufacturers face significant challenges when designing reliable shielding solutions, especially for new medical devices.

One of the primary challenges is ensuring compliance with stringent regulatory standards, such as those set forth by regulatory bodies like the FDA and the World Health Organization, around electromagnetic compatibility (EMC) to ensure their products are safe and effective in various healthcare environments.

Another key challenge lies in achieving high levels of shielding effectiveness while maintaining device functionality and minimizing production costs, where advanced expertise from medical device engineers and precision manufacturing techniques comes into play.

Other key challenges faced by my manufacturers include:

Interference from External Sources

Imaging devices, monitors, and communications are just some of the electronic equipment at a medical facility. Each generates electromagnetic fields and could interfere with the operation of sensitive medical devices.

Sensitivity of Medical Devices

Many medical devices, such as pacemakers, defibrillators, and infusion pumps, contain sensitive electronic components susceptible to electromagnetic radiation interference, requiring robust shielding solutions to mitigate risks.

Variability in Operating Environments

Medical devices may be used in diverse environments, including hospitals, clinics, ambulances, and home settings. Each place has unique electromagnetic characteristics and potential sources of interference, necessitating adaptable shielding solutions.

Addressing these challenges demands collaboration between engineering teams, regulatory experts, and precision metal manufacturers to develop innovative solutions that ensure reliable and interference-free operation of medical devices in healthcare settings.

The Crucial Role of RFI/EMI Shielding in Medical Devices

Shielding solutions play a crucial role in protecting sensitive electronics in medical equipment from electromagnetic interference (EMI) and radio frequency interference (RFI).

These shielding solutions, typically composed of specialized metal alloys such as stainless steel or aluminum, are precisely engineered to create a barrier that blocks or absorbs electromagnetic waves. By surrounding sensitive electronic components with these shielding materials, medical equipment manufacturers can effectively prevent external electromagnetic radiation from interfering with the operation of critical devices. This protection ensures the reliable performance and accuracy of medical equipment, safeguards patient safety, and maintains the integrity of diagnostic and treatment procedures in healthcare settings.

As we mentioned earlier, some medical devices are particularly vulnerable to EMI and RFI, putting them at a higher risk of interference due to their sensitivity and reliance on accurate signals for proper function. They include:

MRI (magnetic resonance imaging) machines

MRI machines utilize strong magnetic fields and radio waves to generate images of the body’s internal structures, making them highly susceptible to external electromagnetic interference (EMI). Shielding is essential to prevent interference that could distort imaging results or compromise patient safety.

Pacemakers

These implanted medical devices regulate heart rhythm and are particularly vulnerable to EMI. Shielding is required to ensure a pacemaker’s reliable and interference-free operation, thereby safeguarding patients’ lives.

Infusion pumps

A patient receives medications or intravenous fluids via an infusion pump. The electronic controls on these devices ensure accuracy in dosage and time, so it’s essential to patient safety to protect them from EMI.

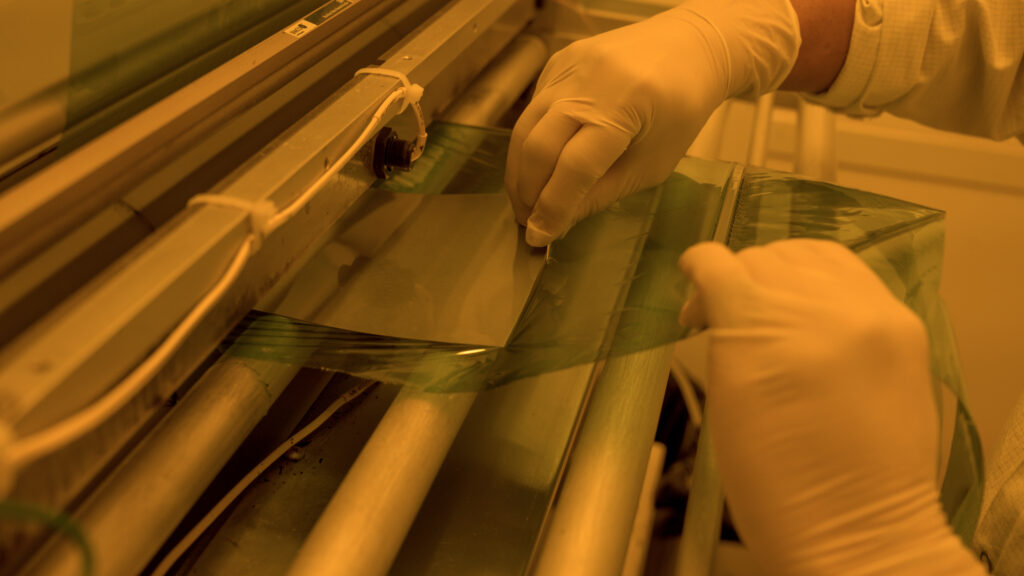

Benefits of Photochemical Etching for Shielding

When it comes to manufacturing shielding solutions, the high precision and efficiency of photochemical etching are superior to other traditional metal fabrication techniques.

Photochemical etching produces parts with high-precision tolerances and complex geometries, making it ideal for industries requiring accuracy and quality. The process delivers intricate designs on various metals with exceptional precision, ensuring the production of specialized items that may be challenging to create using traditional methods.

Photochemical etching also allows for the production of lightweight and thin-profile shielding components without compromising performance or strength, making it ideal for applications where space and weight constraints are critical, such as in medical devices.

Unlike traditional machining techniques such as stamping or laser cutting, photochemical etching does not induce thermal stress or mechanical distortion, preserving the integrity of the metal and ensuring consistent shielding effectiveness.

E-Fab utilizes state-of-the-art photochemical etching technology, allowing precise and intricate etching patterns on various shielding materials. This technology enables the production of customized shielding solutions tailored to the specific requirements of medical equipment.

E-Fab's Customized Shielding Solutions

With years of experience serving the medical device industry, E-Fab understands the unique challenges and requirements associated with shielding solutions for medical equipment. Our industry expertise allows us to provide valuable insights and guidance to clients, ensuring that the customized shielding solutions we produce meet technical specifications and comply with relevant regulatory standards and industry best practices.

As shielding materials experts, we have deep knowledge of the best metals to use for shielding solutions. We understand the properties of conductive metals, metal alloys, conductive coatings, and composite materials and how they work to attenuate or reflect electromagnetic waves

What sets E-Fab apart:

Customization Flexibility

We know that each medical device has unique shielding requirements based on size, shape, and operating environment. Leveraging our expertise in photochemical etching, we can accommodate a wide range of customization needs, from intricate shielding patterns to specific material properties, ensuring optimal performance and compatibility with medical equipment.

Advanced Photochemical Etching Technology

Utilizing state-of-the-art photochemical etching technology that allows for precise and intricate etching patterns on various shielding materials, we can produce customized shielding solutions tailored to the specific requirements of medical equipment.

Engineering Excellence

Boasting a team of skilled engineers possessing in-depth knowledge of shielding materials, etching processes, and design optimization techniques, we ensure the production of high-quality EMI shielding solutions that meet stringent performance standards.

Quality Assurance

We’re committed to delivering excellence in every aspect of our operations. We adhere to strict quality control measures throughout the photochemical etching process, ensuring that our medical device shielding solutions meet the highest precision, reliability, and durability standards.

EMI/RFI Shielding Specialists

As technology advances and the use of electronic devices increases, the need for effective EMI/RFI shielding in medical equipment will continue to grow.

As trusted experts in medical device shielding, we can design and manufacture customized solutions that safeguard against electromagnetic interference and ensure uninterrupted functionality and patient safety.