E-Fab's Resource Library and Products Gallery

Leaders in Precision Metal Products

With a company-wide commitment to precision engineering and innovation, E-Fab has built a reputation for consistently delivering precision metal parts ready to use in mission-critical applications. Our innovative processes and expert staff ensure that every component we fabricate is of the highest quality.

Known for our experience, expertise, and experimentation, our team of engineers, manufacturers, and quality assurance specialists are relied on for a wide variety of precision metal products that are durable, reliable, and accurate.

Working out of our Santa Clara, California headquarters, we produce globally recognized quality parts for leading technology companies, defense contractors, medical equipment manufacturers, and innovators.

As a TPC Company, we’re a proud member of The Partner Companies group of specialty manufacturers. As a customer, you can leverage the experience, materials, capabilities, and expertise shared amongst the network.

Explore our diverse range of precision metal products made from various types of metals and see what we can do for you.

Innovative Product Design. High Precision Parts.

More than just a process, our strategic approach to product design is what positions E-Fab at the forefront of precision metal manufacturing.

It’s no secret that the quality of your product design determines the success and quality of the final product. That’s why at E-Fab, we leverage decades of engineering experience we work with you to produce parts and components that ensure the highest form, function, and performance.

We are focused on pushing your design to the next level by leveraging the latest cutting-edge technology and engineering principles. Our engineering philosophy and expertise revolve around innovation, so we aim to blend ingenuity and precision so that every project coming out of E-Fab meets exacting standards and tight tolerances.

The synergy between customer designs, our engineering and manufacturing expertise, and our proven quality assurance system means E-Fab continues to deliver superior, reliable, and precisely engineered precision metal parts and components.

Product Showcase

Our portfolio of products covers a wide range of accurate, reliable, and durable parts used for a nearly endless number of applications for some of the world’s leading industries.

With our company-wide commitment to innovation, we engineer and manufacture precision metal products with complex or intricate geometries and tight tolerances for applications where failure is not an option.

Our precision manufacturing services are relied on for a wide variety of precision metal products that are durable, reliable, and accurate.

Let’s take a close look at some of our key products and their applications:

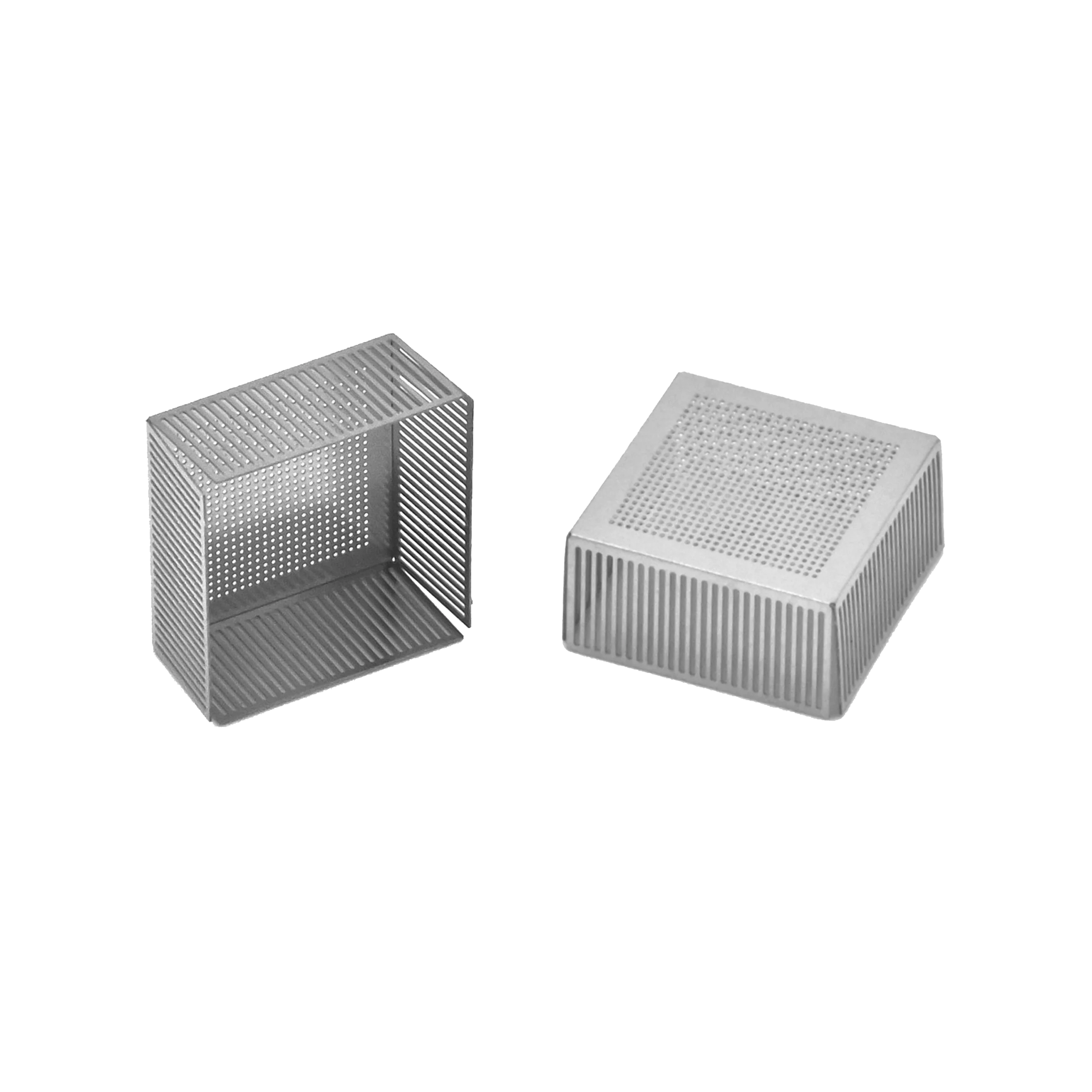

Stainless Steel Shields:

Our custom metal shields are relied on for a number of mission-critical applications within the electronics industry. These precision stainless steel shields are used to protect electronic components from electromagnetic interference (EMI) and radio-frequency interference (RFI), ensuring the stable operation of electronic devices. They are also crucial for thermal management, dissipating heat from sensitive electronic components, and helping maintain optimal operating temperatures.

Brass/Beryllium Copper Contacts:

Our custom-made contacts play a crucial role in aerospace, semiconductor, and defense industry applications. Our brass contacts are used in aircraft electrical systems for reliable connectivity, ensuring stable operation under various environmental conditions. Our beryllium copper contacts are used to shield semiconductor components from electromagnetic and radio frequency interference and maintain signal integrity.

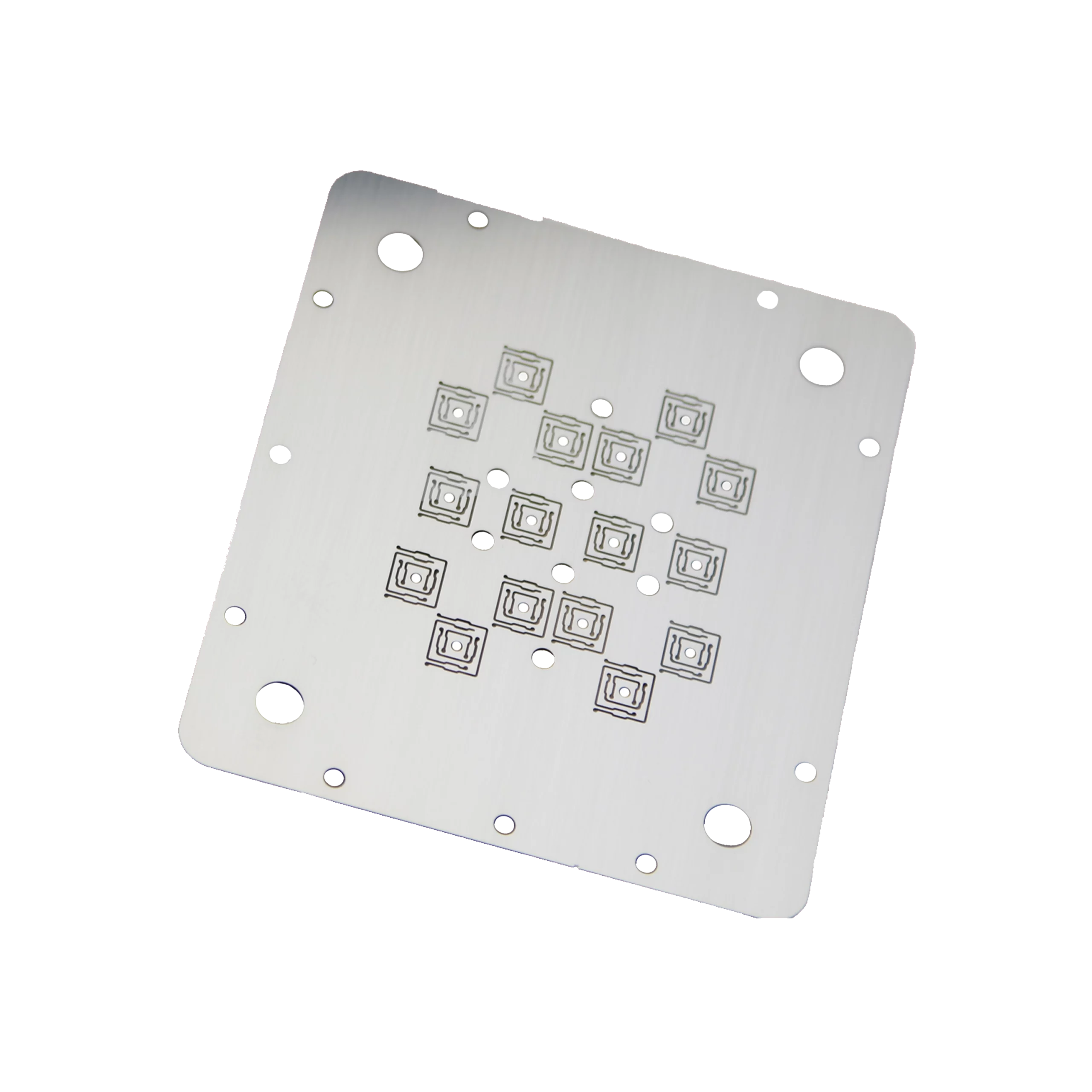

Beryllium Copper Microwave Circuit:

Our beryllium copper microwave circuits are critical in radar systems for defense and aerospace, offering durability and high conductivity for effective signal transmission.

Explore our diverse range of precision metal products in the Gallery below. Our Gallery shows what we can do but not the exact parts we’ve produced for customers.

Product: Shield

Material: Stainless Steel

Industry: Electronics

Product: Waveguide

Material: Brass

Industry: Microwave

Product: Flexure

Material: Stainless Steel

Industry: Electronics

Product: Contact

Material: Brass

Industry: Defense I Aerospace

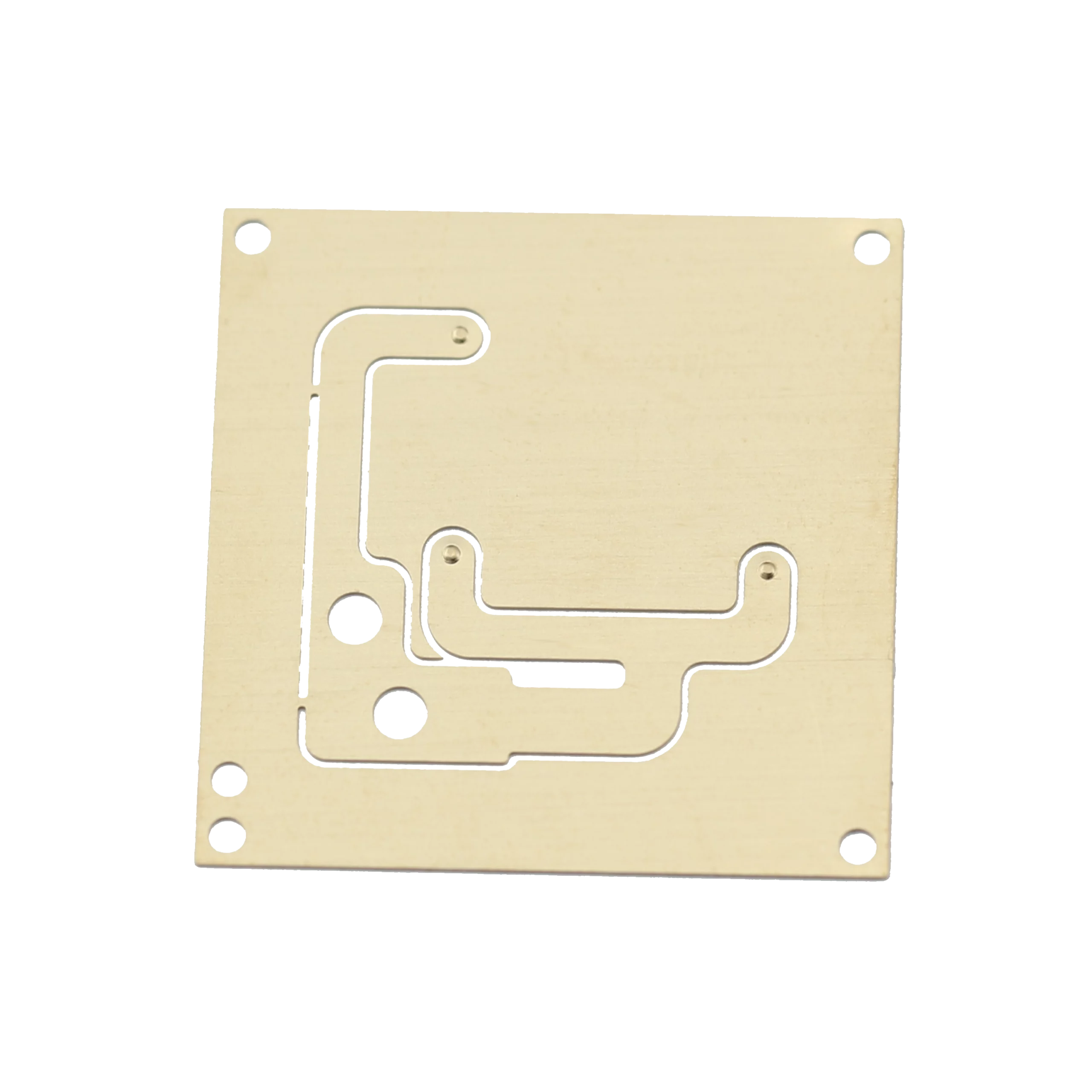

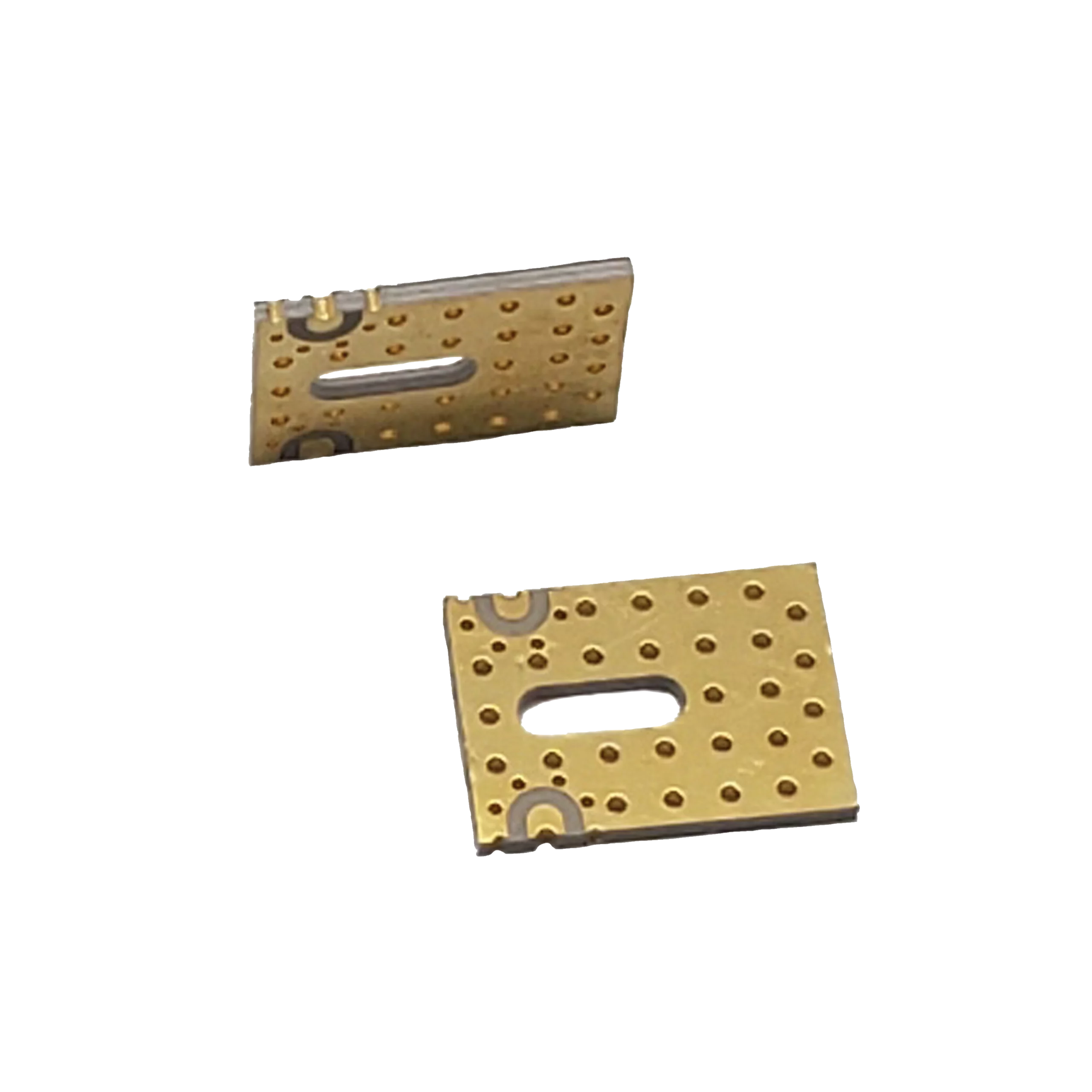

Product: Shield

Material: Brass

Industry: Communications

Product: Contact

Material: Beryllium Copper

Industry: Semiconductor

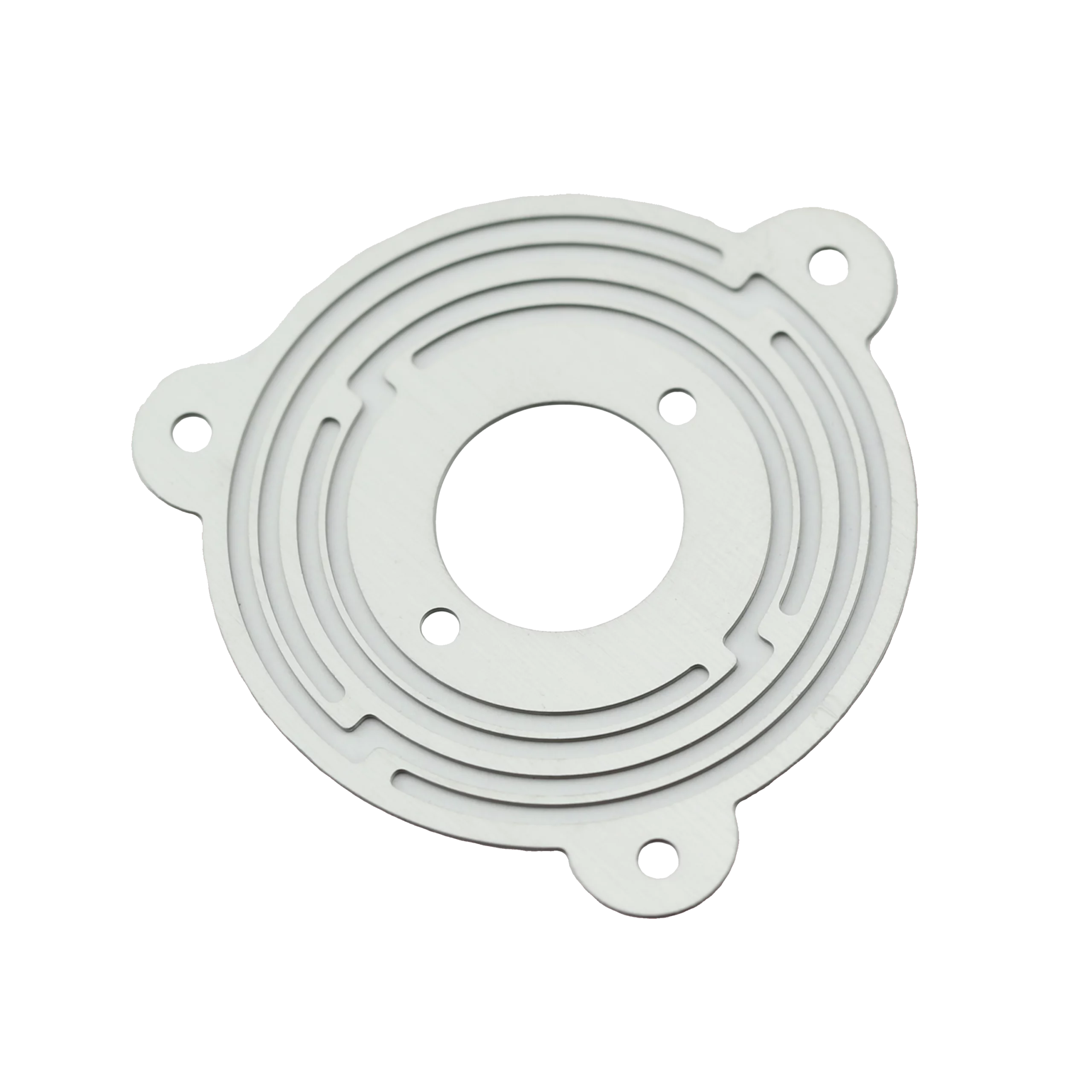

Product: Flexure

Material: Stainless Steel

Industry: Semiconductor

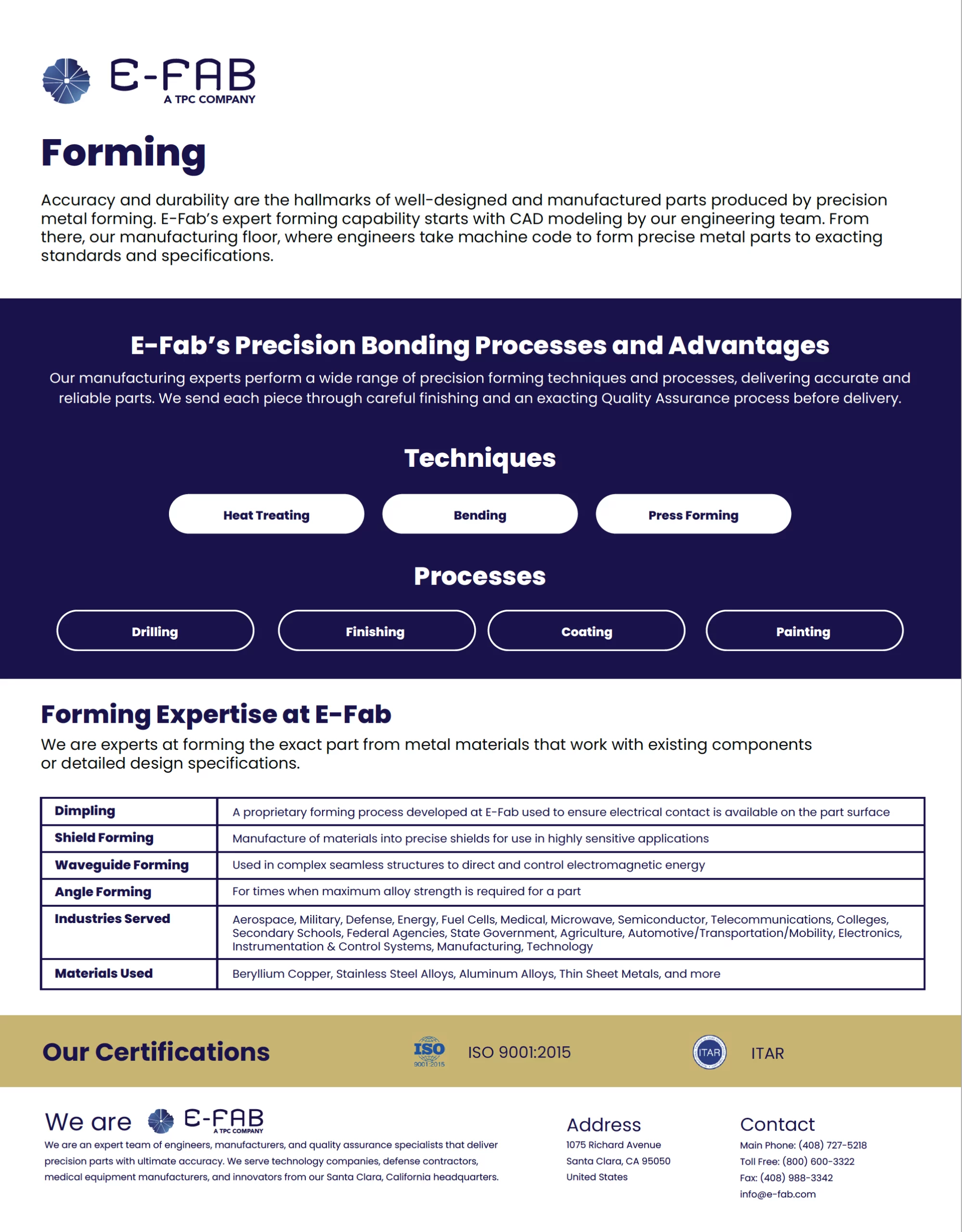

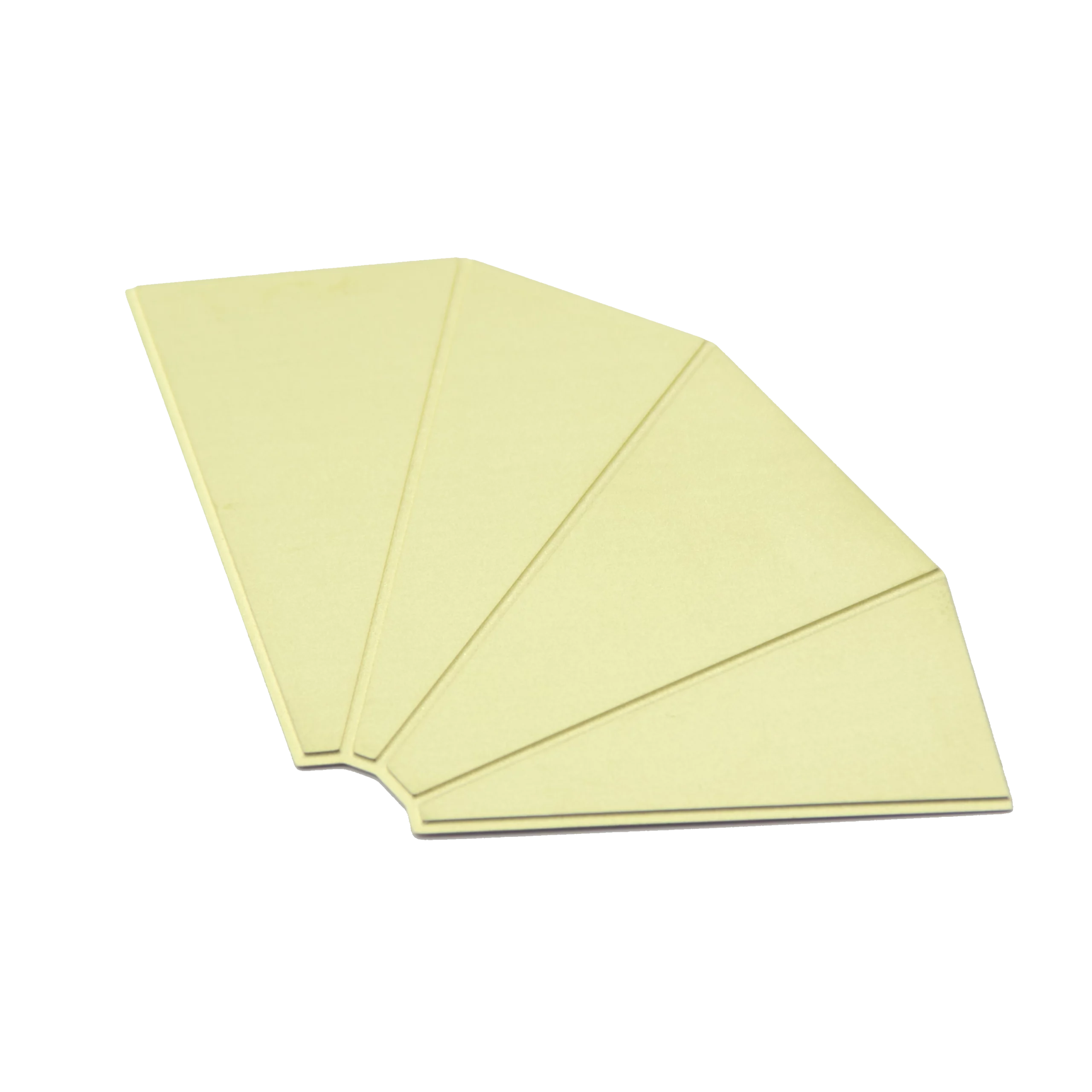

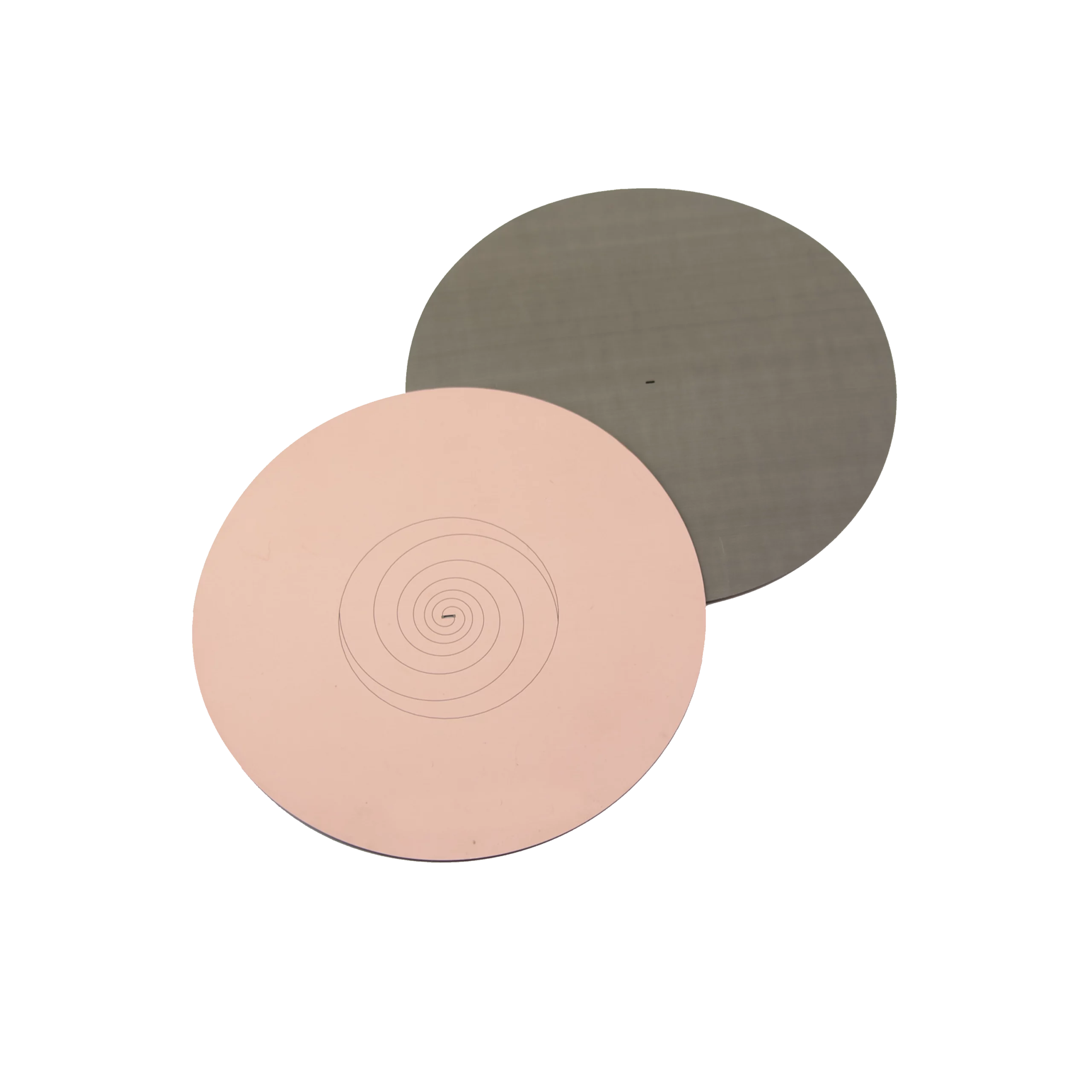

Product: Logarithmic Spiral

Material: High Frequency Laminate

Industry: Defense I Aerospace

Product: Microwave Circuit

Material: Beryllium Copper

Industry: Defense I Aerospace

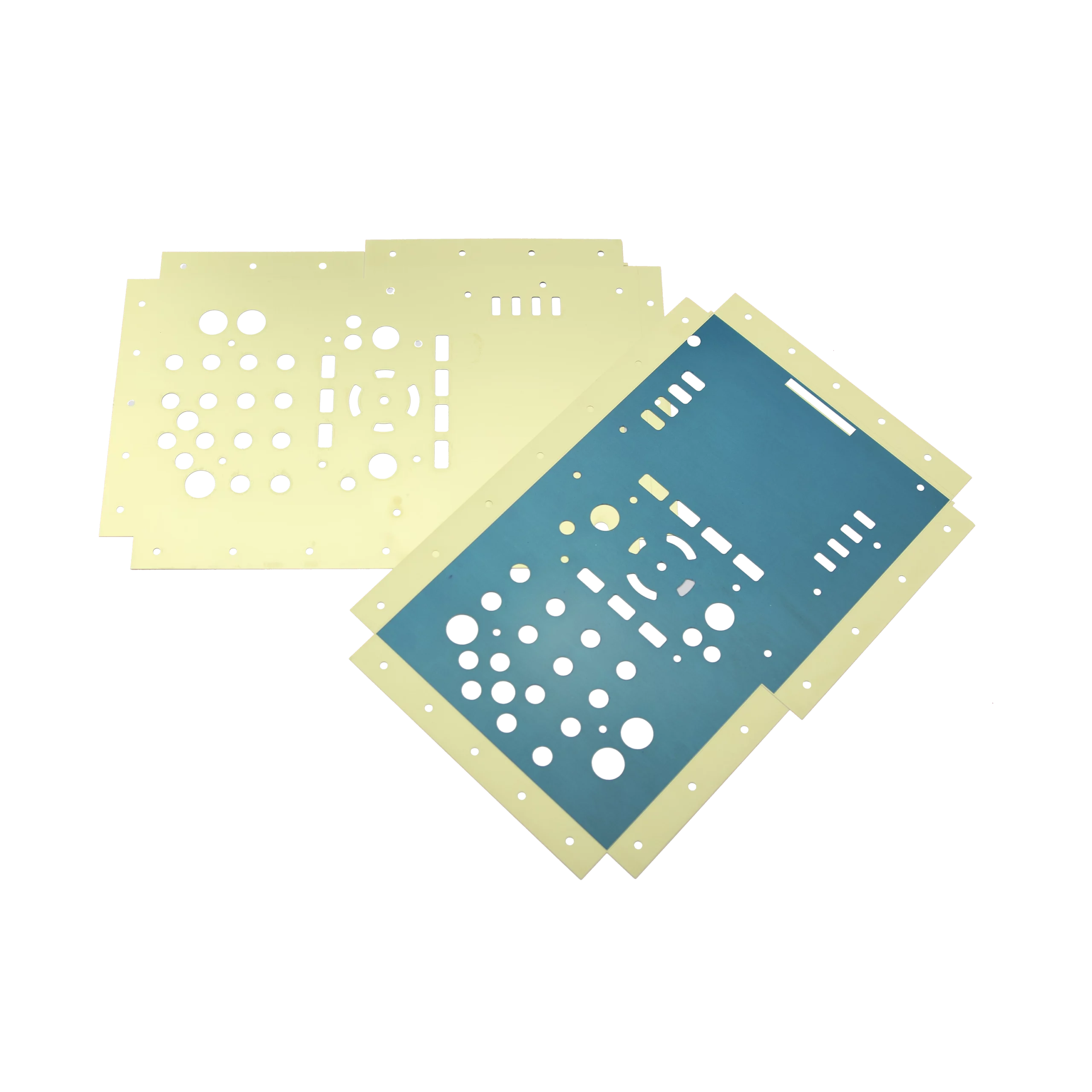

Product: PCB

Material: High Frequency Laminate

Industry: Defense I Aerospace

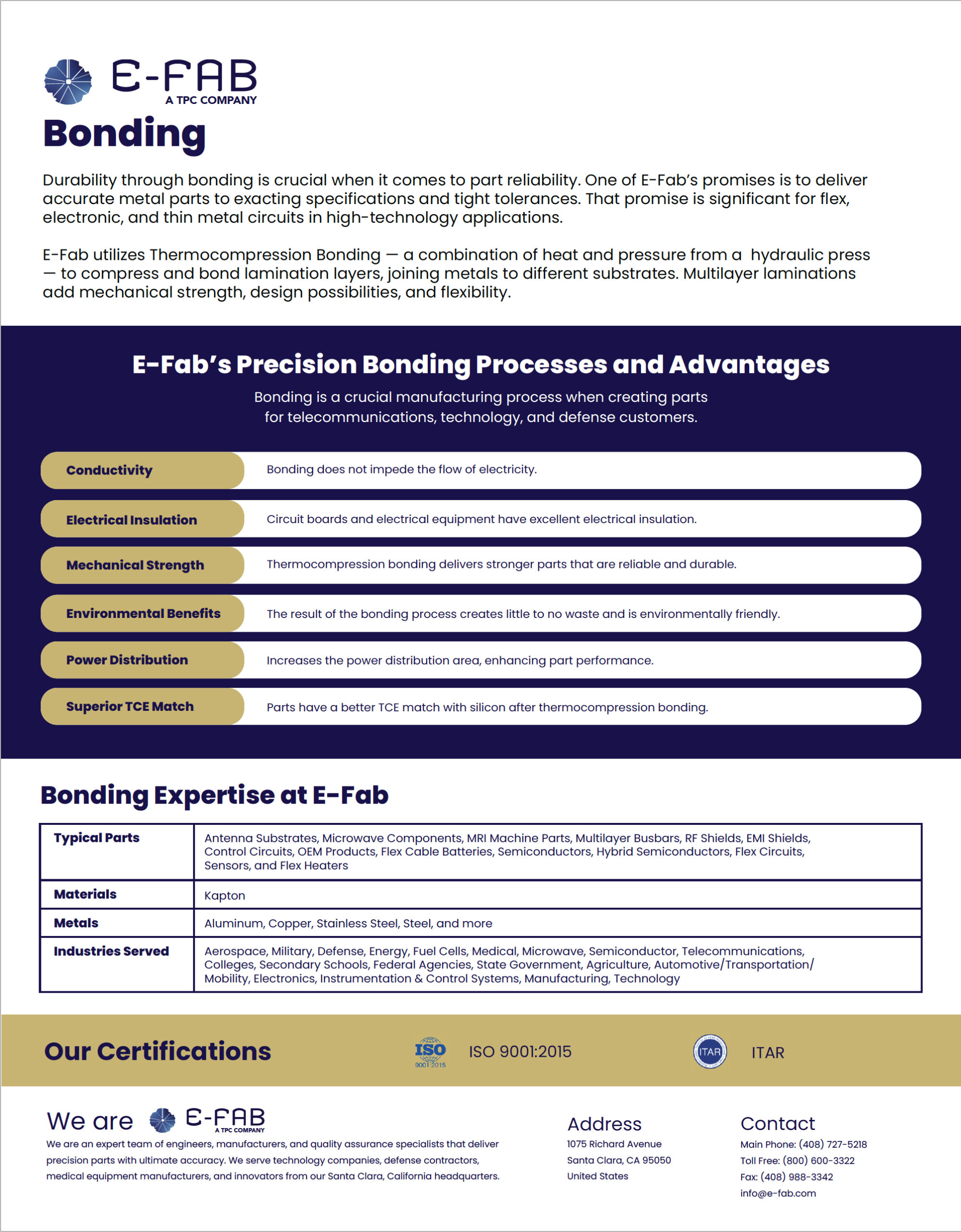

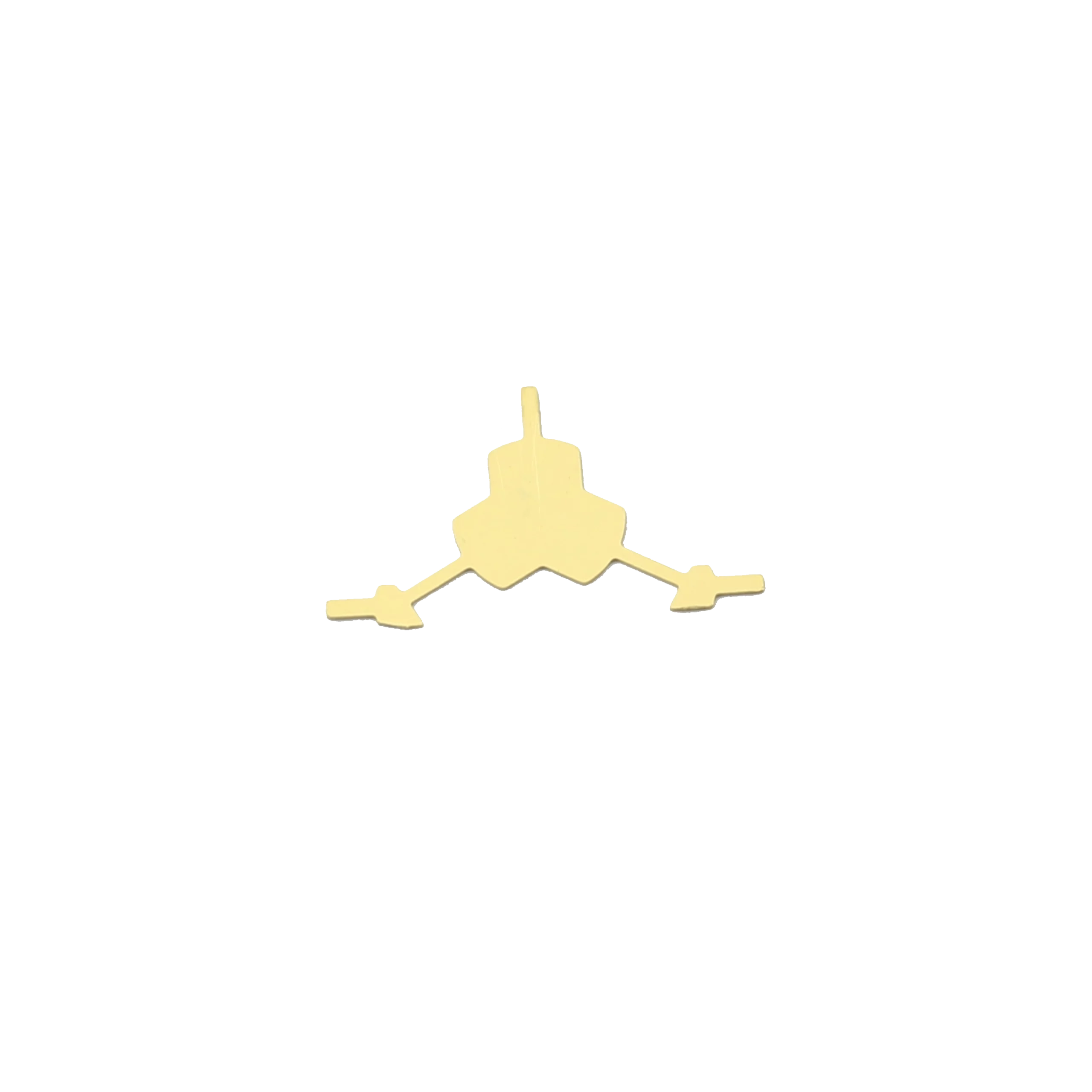

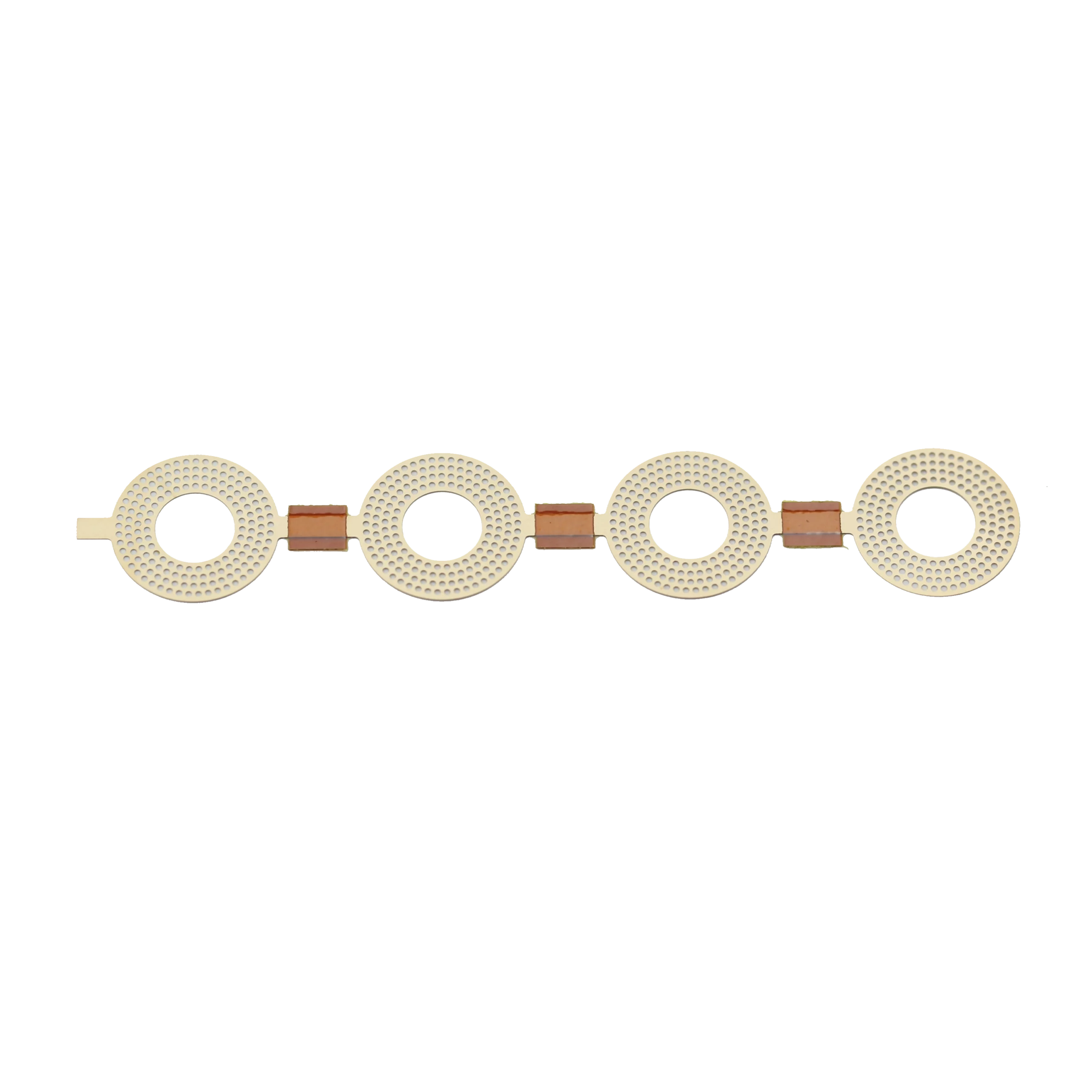

Product: Contact Terminal

Material: Beryllium Copper

Industry: Defense I Aerospace

Product: Microstrip

Material: High Frequency Laminate

Industry: Defense I Aerospace

Precision Metal Products For Any Industry.

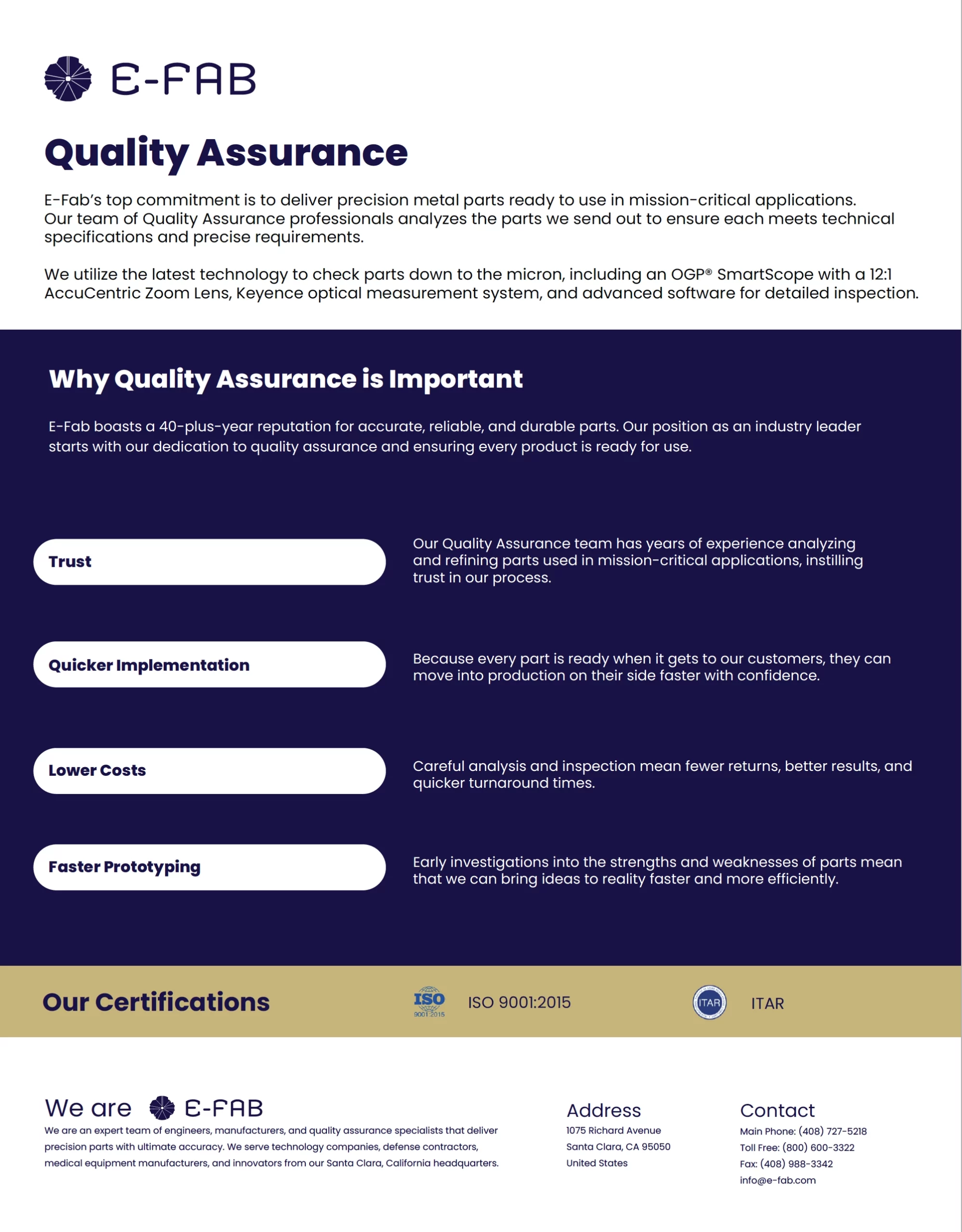

E-Fab boasts a 40-plus-year reputation for accurate, reliable, and durable parts. Our position as an industry leader starts with our dedication to quality assurance and ensuring every product is ready for use.

From leading-edge technology companies and defense contractors to medical equipment manufacturers and innovators, our team of engineers, manufacturers, and quality assurance professionals have partnered with customers to deliver precision metal products for a range of industries.

We deliver parts for use in highly sensitive applications where failure is not an option, so we analyze the parts coming off our manufacturing floor to ensure precision and perfection. E-Fab’s QA specialists utilize OGP SmartScope Flash technology for multi-sensor dimensional measurements through a Zoom 12:1 AccuCentric Zoom Lens. This comprehensive approach guarantees the accuracy of each component, especially crucial for intricate assemblies. Additionally, our commitment to quality extends to meticulous heat-treating processes, ensuring that the thermal properties of the metal components meet the exacting standards required for their intended applications.

As a PCMI-certified company, we ensure our customers receive PCM components manufactured with precision, reliability, and uncompromising quality. Our commitment to PCMI standards sets us apart as a trusted partner in providing high-quality solutions for various industries.

Our ISO 9001:2015 certification signifies our commitment to meeting customer requirements and consistently delivering high-quality products. It demonstrates that we have implemented robust quality management systems that align with internationally accepted best practices.

Our ITAR compliance is integral to our commitment to excellence and customer satisfaction. By adhering to the ITAR regulations, we protect sensitive information, maintain compliance with export controls, and provide our customers with the highest service and quality in the defense industry.

What We Build

If you can think it, we can build it.

At E-Fab, our mission is to deliver engineering and manufacturing solutions to power our customers’ businesses.

Experts in precision, our engineers, manufacturers, and quality assurance specialists turn ideas into precision parts through collaboration, engineering, and expert machining processes.

Blending experience, expertise, and experimentation, we deliver precision parts that are durable, reliable, and accurate for leading industries like technology, aerospace, communications, and defense.

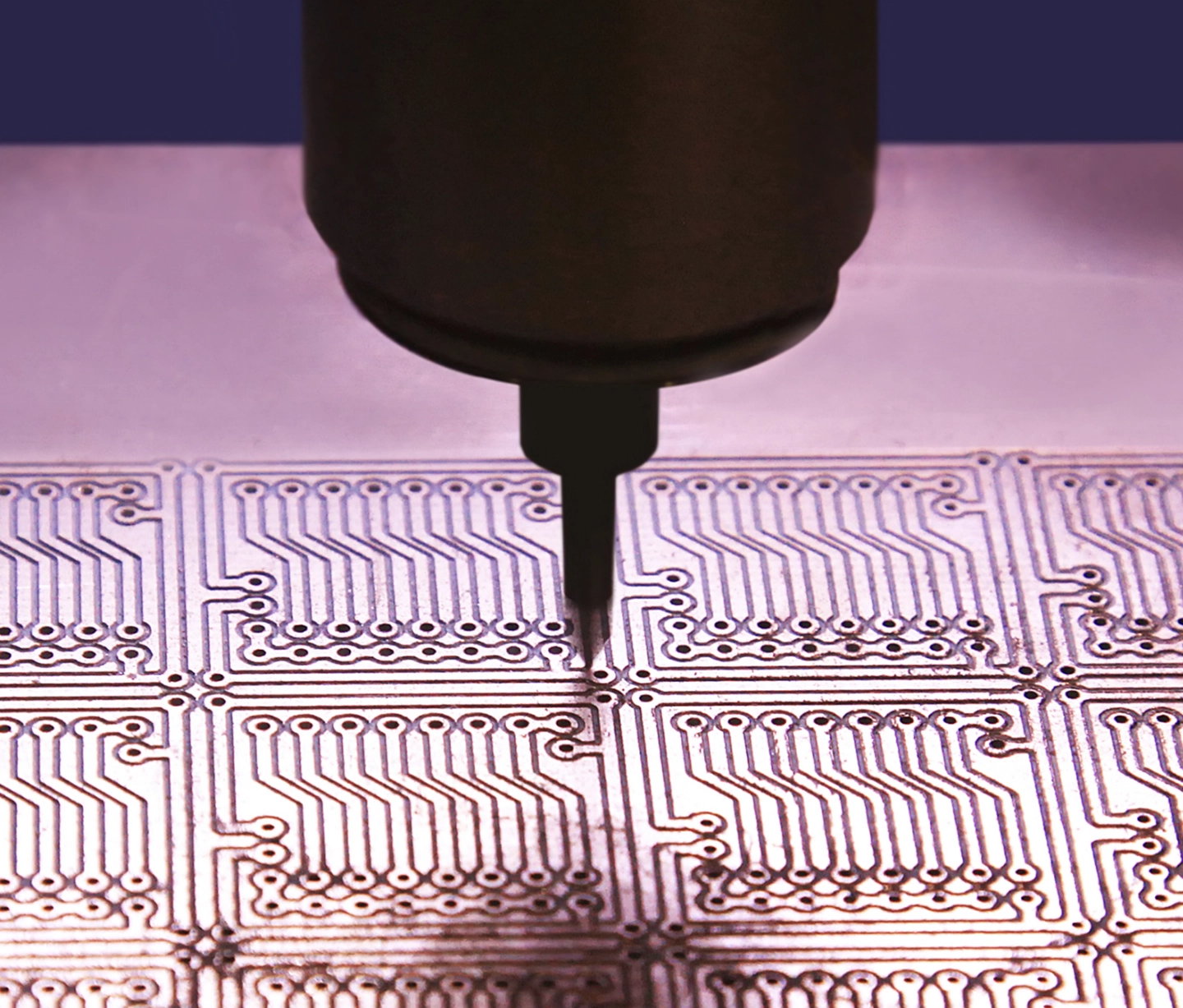

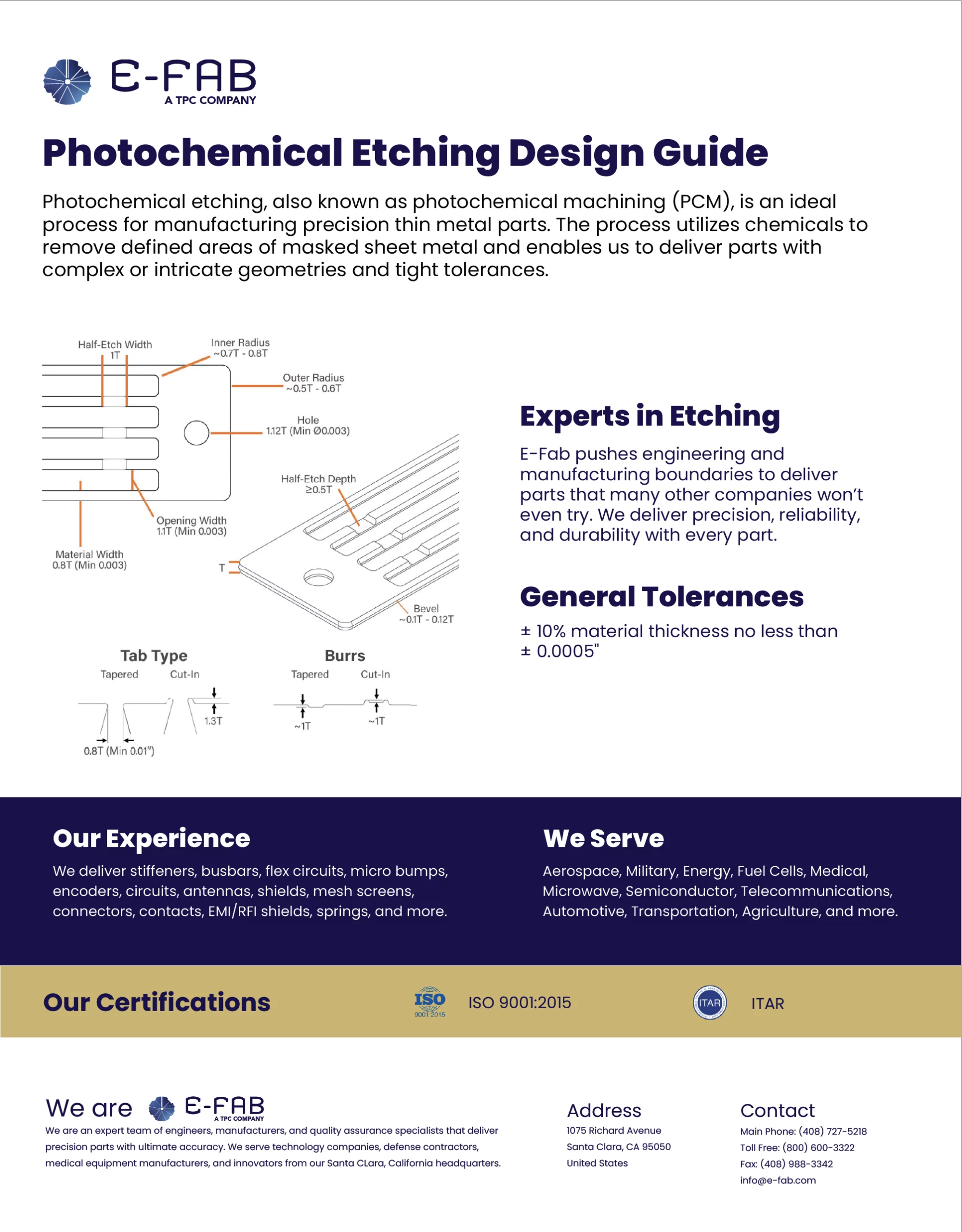

Known for our specialties in photochemical etching, forming, bonding, high-frequency laminate processing, and delivering accurate parts with tight tolerances, our precision metal products are used in dozens of mission-critical applications.

Precision Metal Product Resources

To show our experience and help customers understand the approach and processes behind precision metal manufacturing, we’ve developed a range of helpful resources covering a wide variety of topics.

From our Photochemical Etching Design Guide and our Engineering Resource Paper right through to information on Why R&D is Important, you’ll find everything you need to know about the design, manufacture, and quality control of precision metal parts.