Common use cases for PCE of Molybdenum

In this article, we look at what makes PCE and molybdenum such a powerful combination, the key applications of chemically-etched molybdenum, and what makes E-Fab the trusted partner in molybdenum etching.

In this article, we look at what makes PCE and molybdenum such a powerful combination, the key applications of chemically-etched molybdenum, and what makes E-Fab the trusted partner in molybdenum etching.

Examine the properties that make military-grade titanium so powerful, where it’s used in critical defense applications, and why this wonder metal has become the trusted choice for the defense industry.

Engineers call for titanium because of the material’s strength and versatility. In this article, we look at why engineers view titanium as a valuable metal, discuss the versatility of etched titanium, its unique advantages, and where you can find titanium etched parts across many industries.

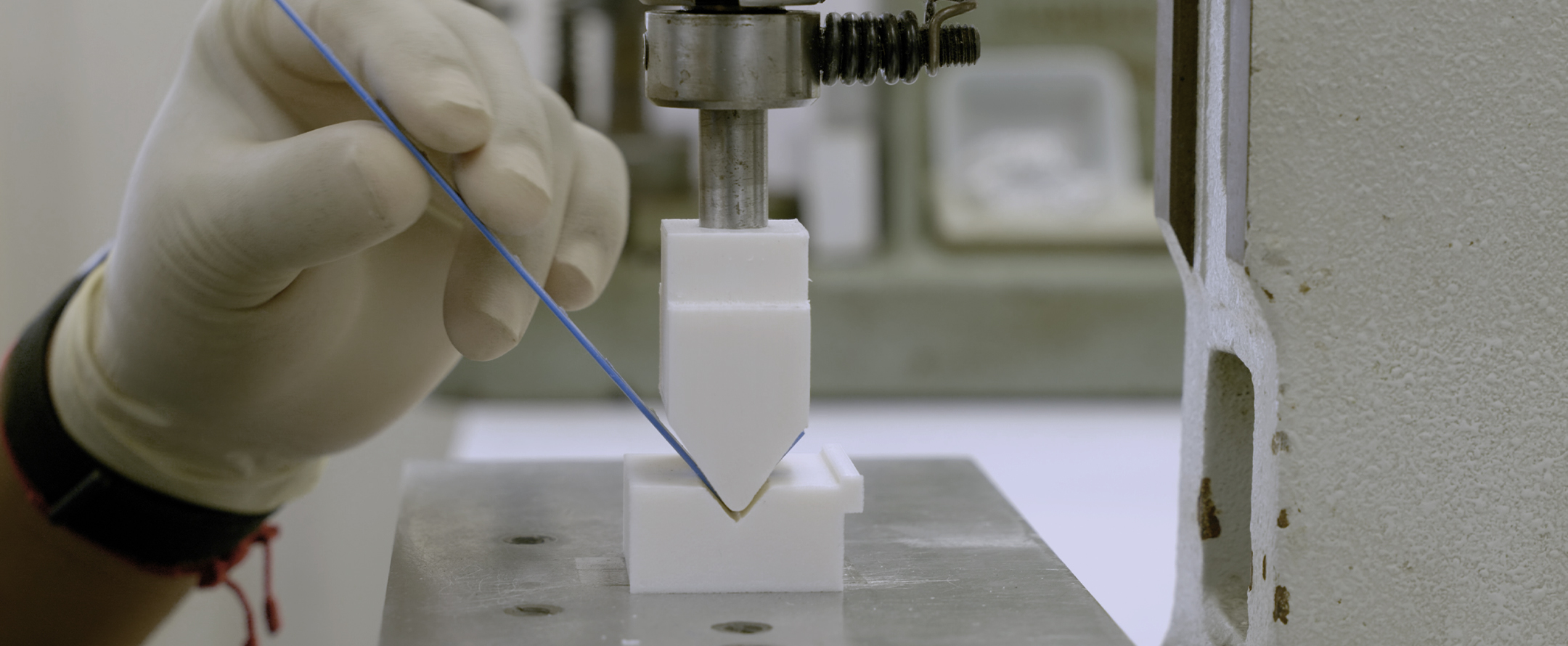

In this article, we examine the main differences, benefits, and drawbacks of chemical etching vs. laser cutting so you can make an informed decision about your manufacturing needs.

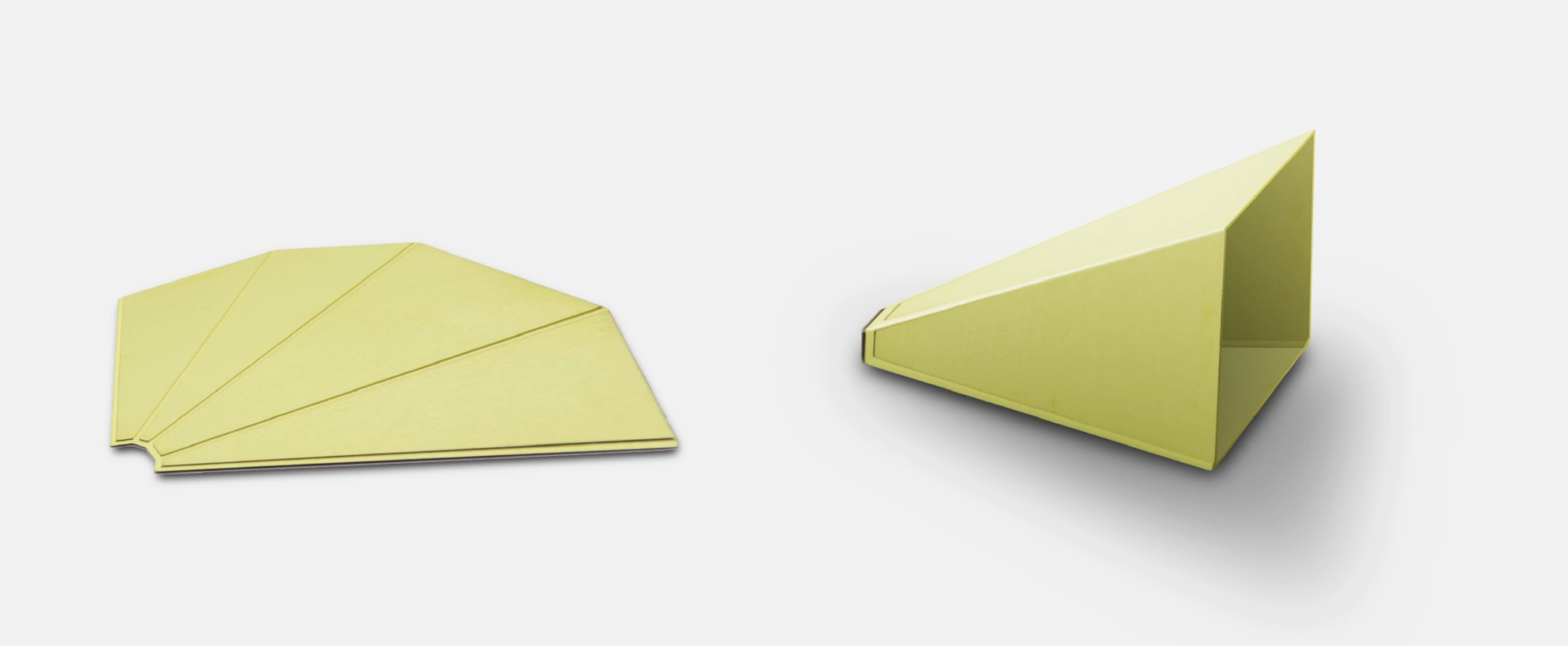

In this article, we break down the key differences between shield, waveguide, and angle forming processes so you can make an informed decision when selecting your manufacturing partners.

Explore the impact interference can have on medical device performance and the critical role RFI/EMI shielding continues to play in protecting sensitive electronics in medical equipment.

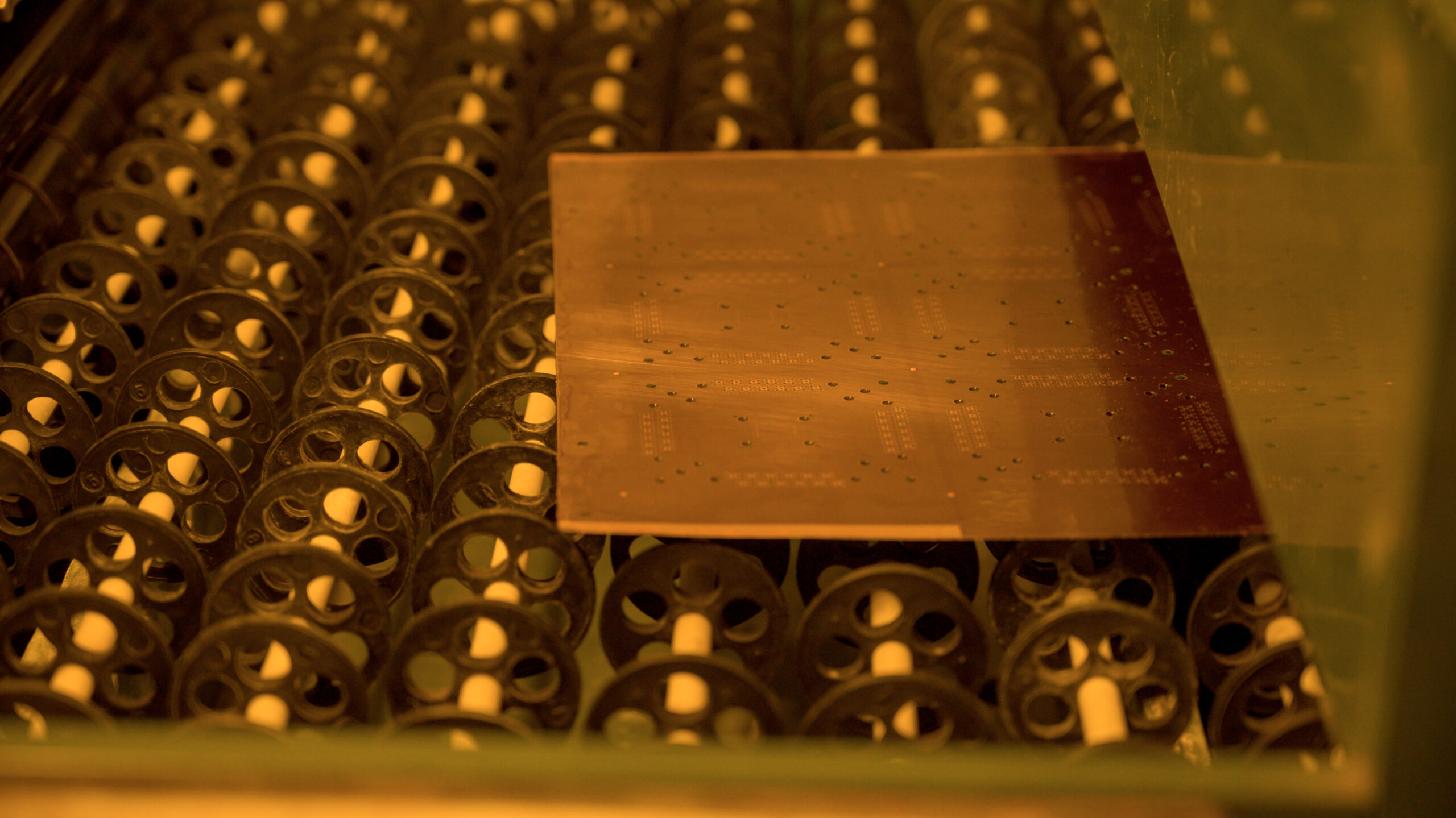

In this article, we look at the advantages of photochemical etching, the parts it can produce, and the reasons why it’s shaping the future of precision manufacturing.

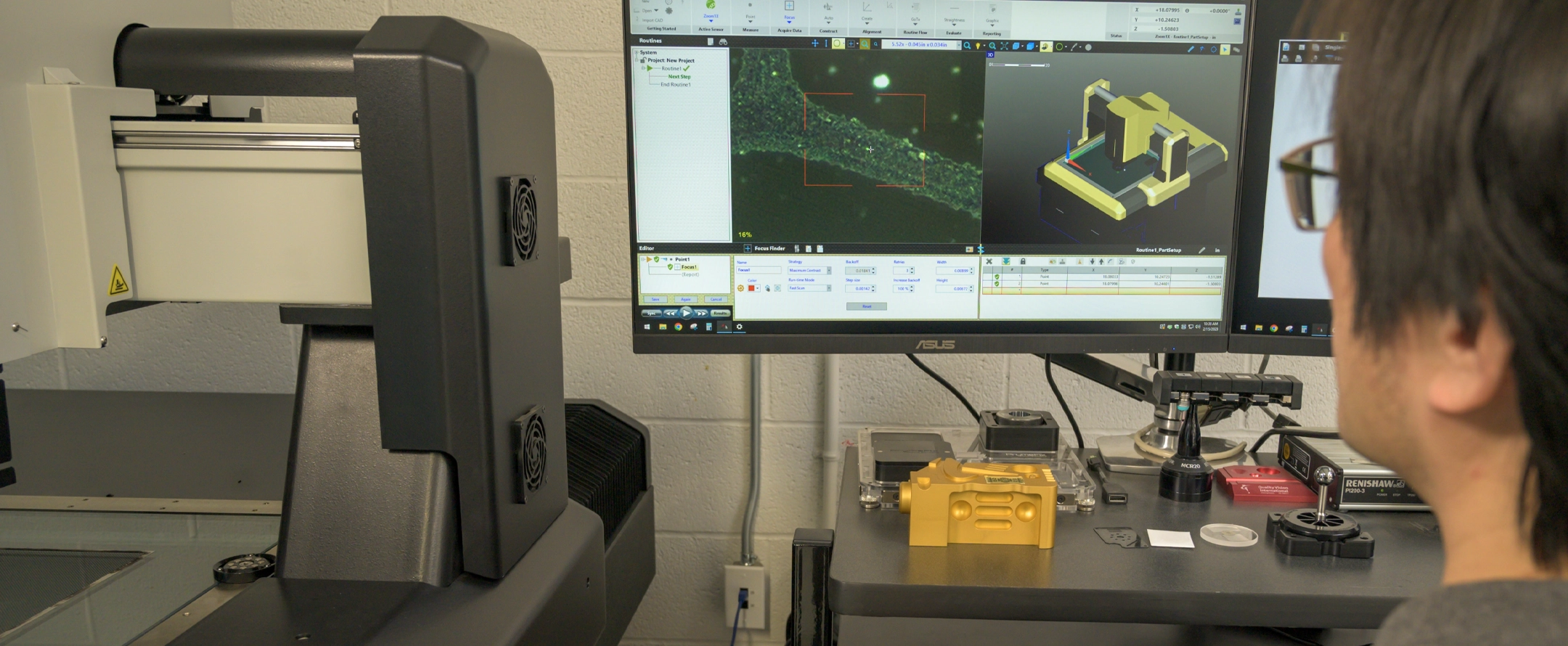

In this article, we explore the role precision plays in engineering and how it’s shaping the landscape of modern manufacturing.

In this article, we discuss how to achieve precise metal fabrication cost-efficiently, which can be particularly important when dealing with large production volumes.

As the metal manufacturing domain forges ahead, metal prototyping stands out, owing to modern technologies such as CNC machining, laser cutting, and direct metal laser sintering. These innovations not only streamline design testing but also bolster cost efficiency and accelerate development.