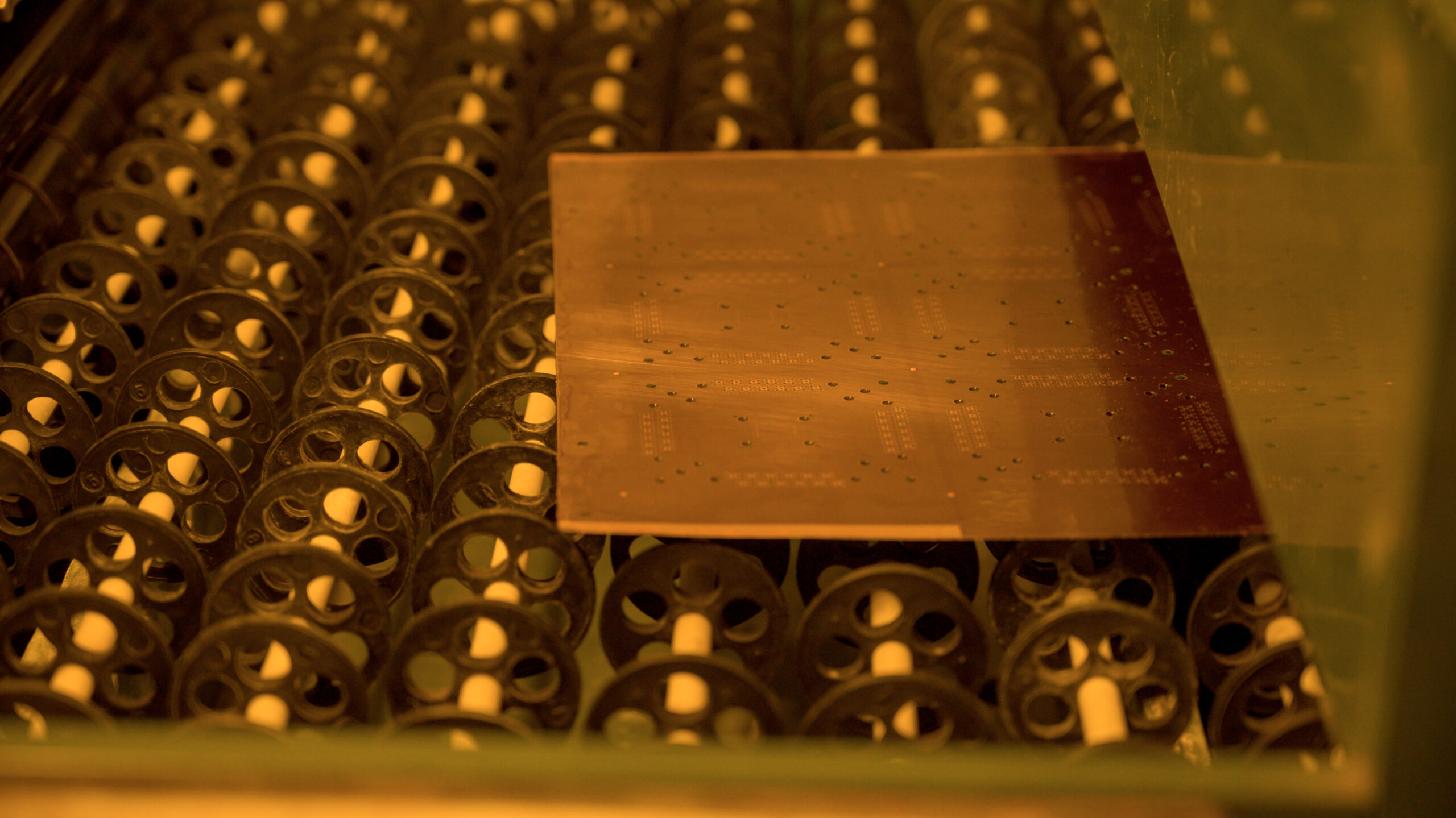

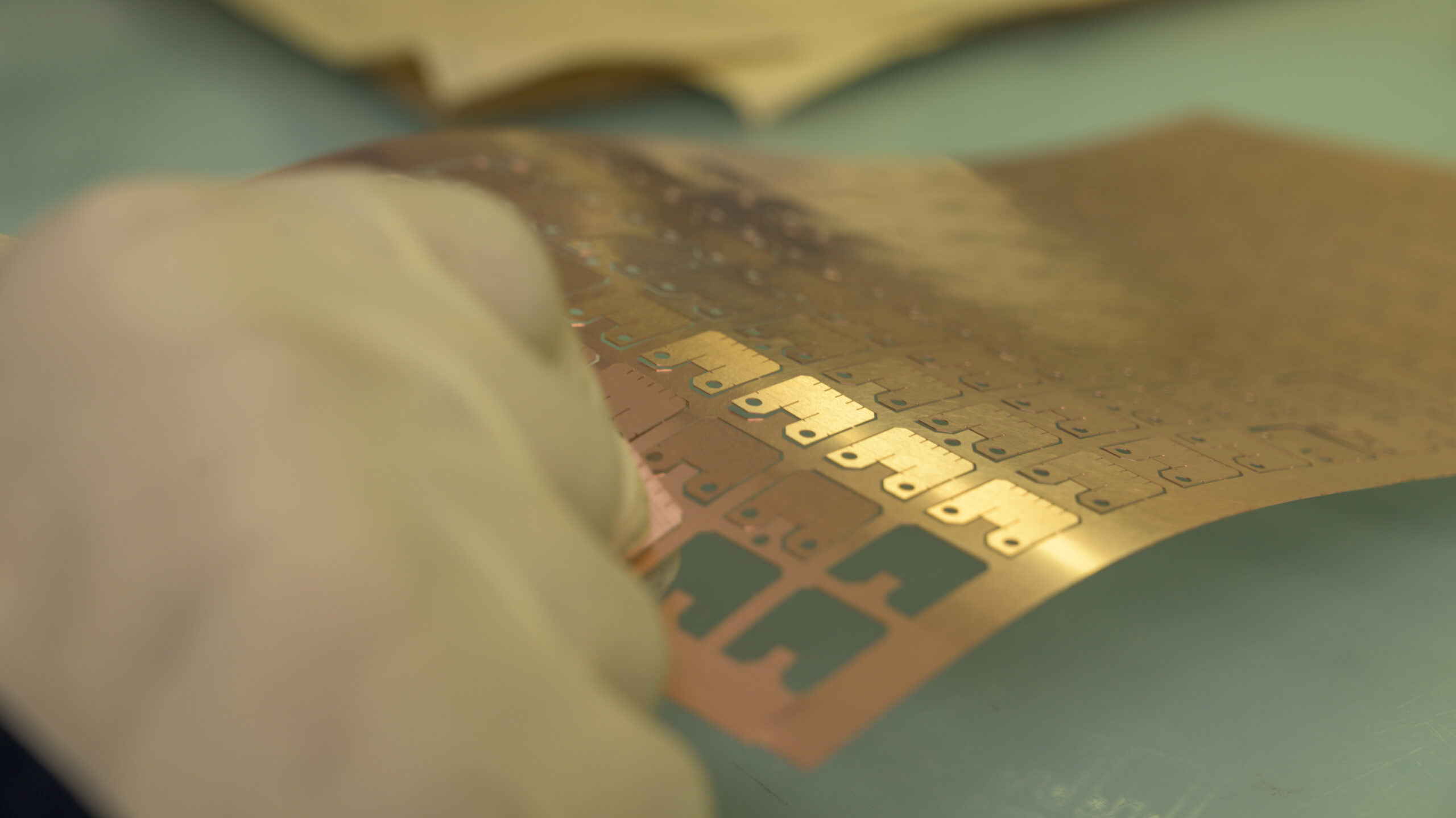

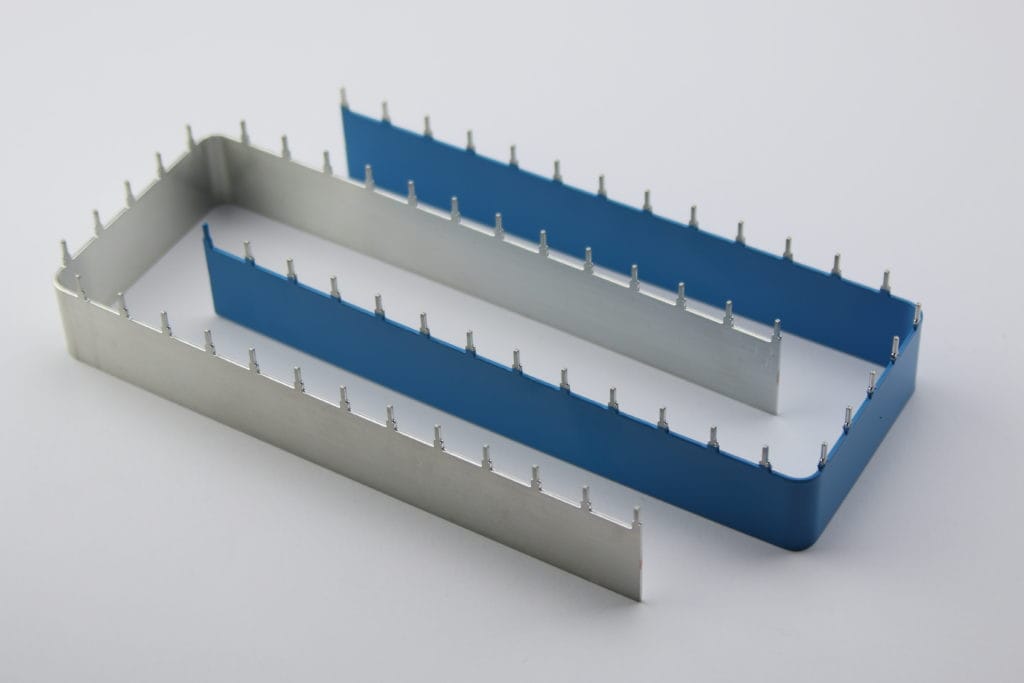

Known as a remarkable refractory metal, molybdenum has quickly become a powerful and popular choice for precision manufacturing. But why is that? The secret lies in its superior properties. Boasting a unique combination of high melting point, exceptional strength, excellent thermal and electrical conductivity, and corrosion resistance, molybdenum offers enhanced performance, durability, and reliability for components in critical applications across various industries. Its low coefficient of thermal expansion, high elastic modulus, and high melting point make it particularly suitable for